If you’re a power plant supervisor, you’ve undoubtedly been forced to find a worker during off-hours on the spur of the moment. New tools are being used today that allow…

Coverage of every aspect of gas-fired power plant design, construction, and O&M, including combined cycles, HRSGs, cogeneration, and LNG.

If you’re a power plant supervisor, you’ve undoubtedly been forced to find a worker during off-hours on the spur of the moment. New tools are being used today that allow…

When many of us pick up our smartphones and take a panoramic photo, we probably think that’s a neat feature. But for inspection personnel at a nuclear energy facility, the…

Utilities and power plant equipment providers know that maximizing the value of their assets includes keeping them maintained and online. Minimizing downtime is critical, certainly when it comes to keeping…

Power plants are challenged to generate value from their data, but this can be a tedious and slow process, with uncertain outcomes. Now, as shown in these use cases, data…

Analysts who spoke with POWER differ slightly on the numbers, but they all agree that U.S. demand for natural gas for power generation will continue to rise. Supply should not…

![POWER Digest [March 2018]](https://www.powermag.com/wp-content/uploads/2016/08/stock_mpw-coal-plant_muscatine-power-and-water.jpg)

ABB Receives Contract to Upgrade, Expand Combined Cycle Plant A consortium including Doosan Heavy Industries and state-owned construction company PT Hutama Karya has awarded a $40 million contract to ABB…

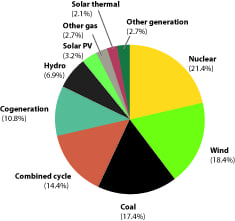

Spanish market and competition regulator CNMC (Comisión Nacional de los Mercados y la Competencia) in a report published on January 24 said a draft government decree to block power plant…

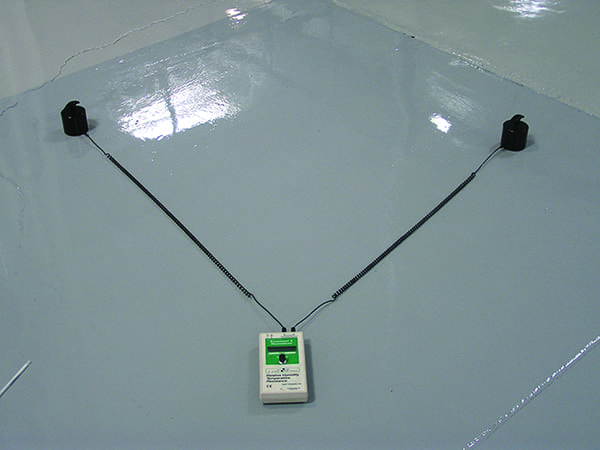

Every element in the construction and operation of power generation plants must be considered to keep such mission-critical facilities running around the clock. The proper flooring can contribute not only…

GE has launched a three-part strategy to address a dismal outlook for its power division that will involve operating in a “leaner, more cost-efficient way,” the company’s head told investors…

An Indiana utility has confirmed it will close three coal-fired power units, replacing that generation with a proposed natural gas-fired facility along with additional solar power. Evansville, Indiana-based Vectren Corp.,…