Industries use a significant amount of water and energy in day-to-day processes, and monitoring boiler water systems can be the key to cutting costs and optimizing resources. SUEZ Water Technologies…

Gas

Coverage of every aspect of gas-fired power plant design, construction, and O&M, including combined cycles, HRSGs, cogeneration, and LNG.

California and Texas—two regions where summer reliability concerns were forecast earlier this year—are suffering extreme temperatures and are scrambling to relieve stress on the grid. The California Independent System Operator…

Poised to drive the future of coal power, many Southeast Asian countries are considering new coal plants with high-efficiency, low-emissions (HELE) technologies, a new report suggests. According to the International…

Successful bid employs flexible MAN 51/60DF units MAN Energy Solutions in consortium with Danish power-plant specialist, Burmeister & Wain Scandinavian Contractor A/S (BWSC), has won the 100m USD contract to…

Lima, Peru- (July 19, 2018) There is a Change in Power happening around the world as a combination of natural gas and renewables dominate new installation activity in the power…

For a decade or more, heat recovery steam generator (HRSG) users have heard that Grade-91 tubing (T-91) is susceptible to microstructure damage from improper heat treatment. Now, a new damage…

NRG Energy will not restart its Dunkirk power plant in western New York, with the company on July 11 saying the cost to reconnect the facility to the state’s electric…

The Anyang plant uses GE’s 7HA.02 gas turbine, D652 steam turbine, heat recovery steam generators and plant control system The new equipment increases the plant’s efficiency by more than 13%…

MAN Energy Solutions has won the order from Oman Liquefied Natural Gas LLC (Oman LNG) to equip a new power plant with nine MAN 51/60 gas engines. The contract was…

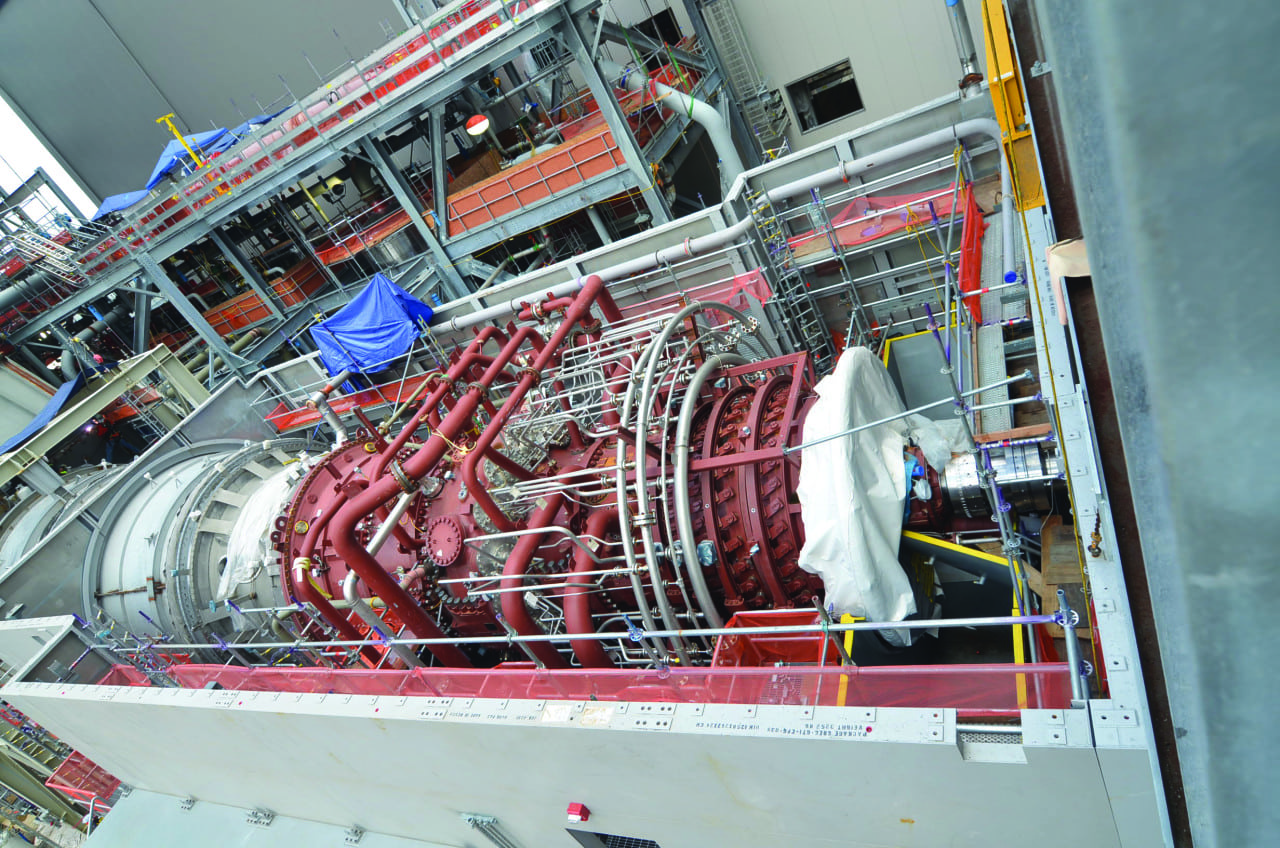

Siemens has introduced a new SGT-800 performance enhancement that is applicable to all existing SGT-800 units with 43-47.5-MW ratings. The new upgrade is designed to provide owners and operators with…