Equipment Showcase: Coatings and Corrosion Control

A major part of maintaining a power plant at peak efficiency is dealing with or preventing damage from corrosion and corrosive objects that can enter air and water intake systems, including pipes and fluid storage areas. Corrosion includes the chemical erosion type of corrosion, along with oxide corrosion—an electrochemical process that occurs when metal is exposed to water and changes in composition—and galvanic corrosion, caused when two different metals come into contact, and the resulting electrical reaction causes and exacerbates damage. Power plant operators know it’s important to protect turbines, pipes, ducts, and other equipment from damage caused by corrosion and foreign objects. Several companies offer products and services for water treatment and corrosion prevention, and some of the leading manufacturers and service companies are featured here.

United Conveyor Solves Corrosion Challenges

|

|

1. The United Conveyor Corp. (UCC) Corrosion-Resistant Mixer/Unloader is designed to reduce the frequency of maintenance, saving time and money. Courtesy: UCC |

The United Conveyor Corp. (UCC) Corrosion-Resistant Mixer/Unloader (Figure 1) is specifically designed to stabilize and fixate fly ash while disposing of high chlorides and other contaminants purged from flue gas desulfurization (FGD) wastewater streams. Corrosive wastewater generated by these streams presents many challenges for disposal. The UCC Corrosion-Resistant Mixer/Unloader is a cost-effective solution to minimize these issues and help customers meet stringent environmental regulations. The product has a completely enclosed chamber to ensure clean operation. Two counter-rotating shafts with standard UCC DURITE H removable paddles, made of 600 BHN abrasion-resistant cast iron, provide superior mixing and dust control. The replaceable paddles and accessible drivetrain allow for easy maintenance. This product solves corrosion challenges with its unique design, uniform conditioning of materials, easy access doors, and operation to reduce maintenance frequency, time and expense. United Conveyor Corp., Waukegan, Illinois

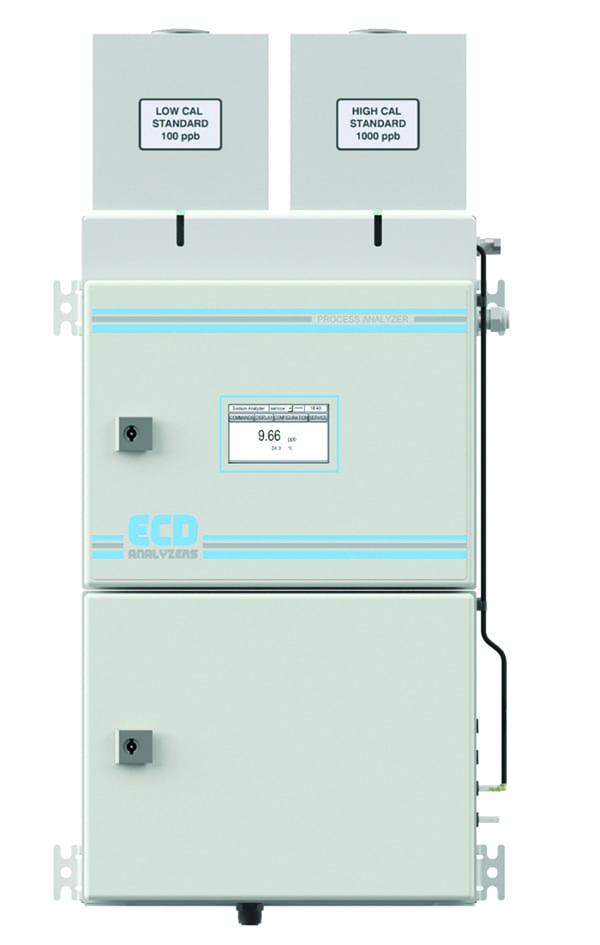

Sodium Trace Analyzer Offers Flexible Operation

|

|

2. Electro Chemical Devices’ (ECD’s) NA6 Sodium Analyzer protects equipment from corrosion. Courtesy: ECD |

Engineers whose processes and plants depend on high-purity and ultrapure water will find the new advanced inline NA6 Sodium Analyzer from Electro Chemical Devices (ECD) sets an industry standard for performance, ease-of-use, and economy to protect equipment from corrosion and ensure product quality. A wide range of sensitive industrial processes and consumer products require high-purity and ultrapure water, including boiler and turbine corrosion control in power generation. ECD’s new Model NA6 Sodium Analyzer (Figure 2) features an advanced glass electrode sensor that measures sodium in water to the parts per billion (ppb), parts per million (ppm), or milligram per liter (mg/l) levels. The sodium sensor’s measurement range of 0.1 ppb to 10 ppb is based on the accuracy of ECD’s proven sodium glass electrode sensor for the online potentiometric detection of low ppb traces of sodium. The ECD NA6 Analyzer is easy to install by a single technician in less than 30 minutes with no special training or tools. Electro Chemical Devices, Anaheim, California

Water Treatment Control Solutions for Plant Operators

|

|

3. Solenis’ expertise includes water treatment chemistries for the power generation industry. Courtesy: Solenis |

Power producers face daunting challenges, from droughts and water constraints to increasingly restrictive emissions standards. Solenis helps power plant operators overcome these challenges. In addition to a broad product portfolio of water treatment chemistries, Solenis offers the latest innovations in cooling tower water treatments, dust control products, and other chemistries optimized for power generation, as well as chemical feed and control equipment. Solenis combines its solutions with applications expertise to ensure power plants perform optimally. Maintaining the optimal performance of cooling and boiler water systems is essential to the energy generation process, and Solenis offers a large selection of water treatment chemistries (Figure 3) for power generation. These chemistries deliver superior results to power producers around the globe, enabling them to improve uptime, reduce water usage, and extend equipment life. Solenis, Wilmington, Delaware

Sensor Ensures Purity of Power Plant Waters

|

|

4. The pHure Sensor series provides accurate pH measurements to ensure water purity in power plants and other facilities. Courtesy: METTLER TOLEDO |

METTLER TOLEDO Thornton’s pHure Sensor series (Figure 4) is valued for providing accurate pH measurements for ensuring the purity of power plant waters. The standard pHure Sensor features a low-resistance pH glass membrane, shielded flow chamber, and a continuous outflow of reference electrolyte for stable measurement. The special, internally pressurized gel electrolyte reference electrode produces similar results to a flowing junction reference but offers more convenient installation and maintenance. The pHure Sensor LE uses free-flowing liquid electrolyte to provide the most-accurate pH measurement available for pure waters. The accompanying stainless-steel housing provides a controlled flow path with minimum volume to encourage corrosion particles to flush through. Mettler Toledo, Columbus, Ohio

mt.com

Cortec Rust Preventative Protects Equipment Surfaces

|

|

5. Cortec offers many products that prevent rust and corrosion, including its Tool & Die Rust Preventative. Courtesy: Cortec Corp. |

Cortec’s EcoAir Tool & Die Rust Preventative is designed to meet the needs of mold, tool, and die manufacturers, and end users, including protection of equipment in industrial settings such as power plants. This liquid rust preventative comes in a non-flammable spray can that makes it easier to use than traditional greases and shipping oils employed to protect tooling assets and all tool steels during shipping, storage, and transport. It is also relatively safer to store than traditional highly flammable aerosols. EcoAir Tool & Die Rust Preventative (Figure 5) is specifically designed for all similar tool and die applications. For power generators, uses include cleaning grease, oils, adhesives, and water deposits off metal surfaces; displacing moisture and protecting metal surfaces from corrosion; and preserving all types of carbon- or alloy-based steel tooling, molds, fixtures, and dies long-term up to 24 months indoors. Cortec Corp., St. Paul, Minnesota ■