Weighing the Environmental Impacts of Wind and Solar

Renewable generation is usually characterized as more environmentally friendly than fossil fuels, and in many respects, that’s true. But there is a growing recognition that solar and wind generation have their own impacts, and an increasing number of manufacturers and generators are looking for ways to minimize them.

Iceland might be about the last place you would look for innovation in solar energy, but if so, you’d be missing something significant—and it concerns Iceland’s own energy supply, as you’ll soon see. But first, some background.

Solar energy is often hailed as the most environmentally benign source of electricity, and once a solar plant is in place, this is arguably true. But getting there has more environmental impacts than you might think. And it starts with the silicon that forms the substrate of the most common types of solar photovoltaic (PV) cells.

Silicon is one of the most common elements in Earth’s crust—about 90% of which is composed of silicate minerals—but producing elemental silicon pure enough for solar PV cells is no simple matter. For one thing, it requires an enormous amount of electricity—roughly half of the energy required to produce a PV cell is consumed in the silicon manufacturing process. Metallic silicon is typically produced by reacting high-purity silica sand in an electric arc furnace, which can require as much as 120 kWh per kilogram of elemental silicon from input to final product. To the extent that electricity is produced with fossil fuels—consider all the PV panels manufactured in China, where coal is the number one generation source—it can negate some of the carbon avoidance from solar energy.

Second, turning raw silicon into finished wafers pure enough for solar cells involves a number of toxic and corrosive materials. The most common method for producing polycrystalline silicon, known as the Siemens Process, involves converting elemental silicon into gaseous form and then growing the silicon crystals through chemical vapor deposition. This process requires hydrochloric acid, and the resulting gas, trichlorosilane, is toxic, explosive, and corrosive. The process also produces silicon tetrachloride, another toxic substance that must be recovered and recycled. Several tons of silicon tetrachloride are produced per ton of polycrystalline silicon, and though it can be recycled to produce silicon and hydrochloric acid, the process is difficult and expensive, so not all manufacturers perform it.

Reducing Toxic Byproducts

Concerns about this process have been raised in a variety of quarters, from both supporters and opponents of renewable energy. But a San Jose–based company has developed a completely different, much more environmentally friendly method of producing solar silicon that has the added benefit of costing half as much as traditional processes and using one-third the energy.

Silicor Materials is planning a facility in Iceland to make it happen. Why Iceland? The island’s abundance of cheap hydroelectric and geothermal power has made it a mecca for metals processing despite its remote location—the tiny nation in fact ranks 11th worldwide in production of aluminum. And it’s the aluminum smelting process that Silicor uses to produce its silicon.

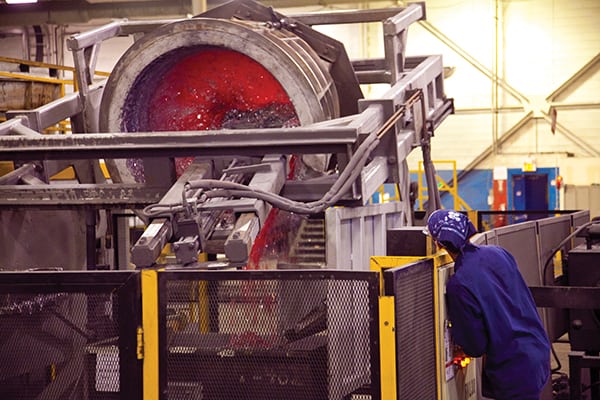

Silicor Chairman and CEO Terry Jester explained the method to POWER. Rather than using gaseous silicon, Silicor’s method partners with the island’s aluminum smelters to extract silicon from the aluminum smelting process, where silicon is viewed as an impurity. Metallurgical-grade silicon is dissolved into an aluminum smelt, and the silicon will crystalize out before the aluminum solidifies as the mixture is cooled (shown in the header photo). The crystallized silicon flakes still contain a coating of aluminum, but this is then removed using hydrochloric acid. Unlike traditional silicon production, however, this process produces polyaluminum chloride, a nontoxic compound that is used in water purification, among other processes. The remaining silicon flakes are then re-melted, and what little aluminum remains forms a thin layer on top of the silicon ingot that can easily be removed (Figure 1).

According to Michael Russo, Silicor’s executive vice president of sales, marketing, and commercial business development, the factory is set to break ground in Grundartangi, Iceland, this fall and will have a capacity of 19,000 metric tons of solar silicon (all of which has been committed to customers) when it reaches full output in 2019. In addition to the environmentally friendly manufacturing process, its location in Iceland will allow it to source 100% of its electricity from renewable energy.

Raising Awareness

But solar PV cells are more than just silicon. The PV manufacturing process involves a range of toxic substances such as hydrofluoric acid, and it produces substantial wastewater and solid waste streams. Treating and recycling that waste costs money, and there have been examples of a few PV manufacturers cutting corners by dumping wastewater rather than treating it. In one widely reported incident, protests over dumping outside a Chinese manufacturer’s plant in 2011 turned violent and the company later faced legal action over it.

Concerns about these issues led the Silicon Valley Toxics Coalition (SVTC), a nonprofit organization that tracks environmental impacts in the tech industry, to begin publishing an annual scorecard ranking PV manufacturers on the transparency and sustainability of their manufacturing processes. To achieve a positive score, the manufacturer needs to support PV panel recycling, clearly report emissions across its supply chain, make efforts to reduce module toxicity and use of heavy metals, and keep in place modern health and safety standards for its workers, among other criteria.

Not surprisingly, scores since the SVTC began the scorecard in 2010 have fluctuated widely given the substantial number of mergers, bankruptcies, and new companies entering the field. And, since the scorecard relies on self-reported data, manufacturers that did not participate in the survey tend to have low scores. Still, the scorecard shows that at least some manufacturers are making substantial efforts to reduce the impacts of their manufacturing processes. Three major companies—SunPower, SolarWorld, and Trina—all achieved scores above 90 on the 2015 scorecard.

Other efforts to reduce solar PV impacts include an embrace of extended producer responsibility (EPR). EPR is a term used for the idea that the environmental costs of a product throughout its life cycle should be reflected in its market price, typically with some sort of surcharge. (If you bought a computer recently, you may have seen such a fee added on to the purchase price.) While the European Union has an EPR scheme that funds disposal costs for PV panels, no such scheme exists in the U.S. However, the SVTC reports that a number of panel manufacturers have asked the Solar Energy Industries Association to work on this issue.

Birds and Bats and Turbines, Oh My

Unlike solar PV cells, wind turbine manufacturing is relatively benign, or at least little different in impact from traditional turbine generators, since many of the same components are used. Wind turbines using permanent magnets require rare earth elements such as neodymium, the extraction of which can have serious environmental consequences because of the acids used in refining and the frequent occurrence of uranium and thorium in the ores. However, the percentage of neodymium going to wind turbine manufacturing is a small component of worldwide demand for this element, which is used in a wide variety of consumer products as well as electric vehicles.

Much more controversial has been the issue of bird mortality at operating wind farms (Figure 2). Though the scope of the impact has been heavily studied, the reported ranges are quite large. Estimates of bird mortality in peer-reviewed studies vary from wind farm to wind farm, and range from 0 (that is, no fatalities were found) to as many as 10 or more birds killed per turbine per year. Nationwide, a 2013 study reviewing published data concluded that 573,000 birds and 888,000 bats were killed each year at U.S. wind farms in 2012, while another study in 2014 estimated bird deaths at 140,000 to 328,000.

|

|

2. Avian impact. This red kite was killed by a wind turbine blade at the Montes del Cierzo wind farm in Spain. Courtesy: Gurelur |

It is worth noting that generalized totals do not give an accurate picture of the true impact of bird mortality for a variety of reasons. Deaths in different regions and over different periods of the year have different effects on the environment. Mortality rates for different species are not clear, even though deaths of different species also have different impacts. For example, the loss of 10,000 sparrows will have far less effect on the ecosystem than the loss of 10,000 bald eagles.

Data suggest that migratory birds tend to suffer the greatest mortality from wind turbines, accounting for around 75% of all fatalities, according to several studies. Some authors have suggested that deaths for these species are underreported because these birds tend to be small and their carcasses are more easily scavenged and thus less likely to be found during site studies. However, because these species also represent some of the largest bird populations, many studies have concluded that these deaths are ecologically insignificant, especially when viewed in context with deaths suffered by collisions with power lines, buildings, and other structures, and predation by domestic cats.

On Wings of Eagles

Though raptors (eagles, hawks, and related species) make up a small portion of the total bird fatalities (the 2013 study mentioned above estimated 83,000 per year), these deaths are much more significant because these birds are typically apex predators and their population has a direct effect on a wide variety of other species. Thus, it is not surprising that wind turbine raptor deaths have garnered most of the attention.

There is evidence that raptors are attracted to wind turbines as nesting sites, and they are likely more vulnerable to blade impact because of their habits of staying aloft longer and floating on thermal patterns while hunting for prey. One oft-cited study estimated as many as 100 or more raptors being killed at the Altamont Pass Wind Farm in California every year, though this high level of mortality has not been seen at other wind farms.

Some studies have suggested that this disparity exists because most of the turbines at Altamont were constructed before bird mortality was an issue considered during wind farm development and little thought was given to reducing risks. Studies have shown that wind farm location can have a dramatic effect on avian mortality, with poorly sited projects killing far more birds than ones built with more responsible planning.

Older wind farms tend to be higher density than newer projects, grouping turbines much more closely, which can increase avian risk. Such farms are also more likely to have lattice-frame towers instead of the monopoles used by modern turbines, as well as above-ground transmission lines (Figure 3), both of which are known to attract birds.

Adjust Cut-In Speed to Cut Mortality

Though the data are not extensive, there is growing evidence that proper planning and design can substantially reduce avian mortality. A 2010 study from the U.S. Fish and Wildlife Service (FWS) makes a number of recommendations. Among these are assessing avian populations in the area during the planning process, with particular attention to nesting sites, migration routes/stopovers, and the potential for fragmenting existing habitats. Where such factors exist, other sites should be considered. As specific sites are identified, more detailed studies of potential impacts are recommended, particularly of species behavior in the area.

When building the farm, the study recommends placing turbines outside of areas identified as crossing routes and using only strobe lights that fire simultaneously rather than continuous lighting. (This is to avoid attracting insects that in turn attract birds and bats. Several mass mortality events at wind farms have been linked to the use of high-intensity lighting.) Measures should also be taken to avoid creating potential habitats for prey animals such as rabbits and ground squirrels, as these will attract raptors. During operation, avian mortality should be monitored and recorded, and in areas where significant mortality is found, further mitigation efforts should be explored.

One mitigation measure that has been identified is increasing blade cut-in speed, that is, raising the minimum wind speed at which the turbine begins operating. Many birds and bats are more active during periods of low wind, and keeping turbines motionless or at low speed in these conditions has been shown to reduce mortality.

The effectiveness of deterrent devices such as those that generate ultrasonic noise is unclear. Some studies have shown reduced bat mortality, but the data are not extensive. Accordingly, the Department of Energy is currently funding several studies, including one by GE, of deterrent devices to determine whether they could be effective in reducing bat mortality.

Other approaches include using radar to detect approaching birds and automatically shutting down or slowing turbines, but the effectiveness of this method is also not yet known.

Meanwhile, the federal government is struggling with how to regulate avian mortality at wind farms, since many avian species killed by wind turbines—such as bald and golden eagles—are protected by federal law, and causing such deaths is normally cause for prosecution. Duke Energy was fined $1 million in 2013 and PacificCorp was fined $2.5 million in 2014, both for eagle deaths in Wyoming, but enforcement actions have otherwise been rare. (Duke has since taken steps to reduce avian and bat mortality at its 16 wind farms, such as slowing down blades in low wind.)

In 2013 the FWS issued a rule allowing wind farm owners to apply for 30-year permits to kill limited numbers of eagles (technically referred to as “incidental take”), a regulation that was successfully challenged in court by several conservation organizations. In May 2016, the FWS proposed a new rule that would require active monitoring and mitigation of avian mortality, with the permits being reviewed every five years. The proposed rule is open for comment through July 5. ■

—Thomas W. Overton, JD, is a POWER associate editor.