Waste-to-Energy Technology Options Increase but Remain Underutilized

WTE technologies offer cost-effective, near-term solutions for producing baseload electric power, meeting renewable energy targets, and reducing greenhouse gas emissions in the U.S. and other countries. They also present opportunities for improving resource management practices, increasing energy security, enhancing environmental quality, and supporting climate policy goals around the world.

Waste-to-energy (WTE) technologies convert the chemical energy stored in residues associated with human activities into heat, steam, and electricity. Primary fuel sources include municipal solid waste (MSW) and other materials diverted from disposal facilities as well as gases rich in methane that are generated when organic substances decompose in the absence of oxygen.

Among the many available fuel-processing and energy conversion technologies, incineration of MSW and derived fuels in boilers is commercially mature and in common use around the world, as are combustion-based systems that fire gases resulting from uncontrolled anaerobic decomposition of waste buried in landfills and from controlled processing of organic materials in purpose-built digesters. Advanced thermal conversion technologies such as gasification and pyrolysis—which transform MSW into versatile fuels suitable for high-efficiency energy production or direct end use—are finding increasing application but are not yet proven.

Overview of Technologies

State-of-the-art WTE technologies are widely recognized by government agencies as effective resource management solutions and renewable generation options. When incorporated within integrated MSW plans emphasizing reduction, reuse, recycling, and composting, they provide an environmentally sound means of recovering energy from the residual wastes while decreasing the volume of material that must be landfilled by roughly 90%. At landfills, agricultural facilities, and wastewater treatment plants, they generate useful energy while substantially reducing emissions of methane, a greenhouse gas (GHG) with high global warming potential.

Globally, WTE capacity has expanded significantly in recent years, driven largely by policy considerations. First and foremost, many nations have forsaken landfilling as inefficient and environmentally undesirable, leading to a steady increase in the annual tonnage of MSW subjected to energy recovery. For example, a 1999 European Union directive essentially banned the landfilling of combustible MSW fractions in order to control methane emissions, avoid nonproductive use of land and other resources, and prevent water and soil contamination.

In Europe, Asia, and elsewhere, such policies—along with climate change mitigation and renewable energy targets—have motivated the construction of hundreds of mass-burn incinerators, the early commercial application of various advanced thermal conversion technologies, and the proliferation of smaller-scale landfill gas (LFG) and digester gas systems. Frequently, these WTE plants supply heat or are combined heat and power (CHP) facilities; in fact, 18% of the district heating load in Denmark is served by MSW combustion. Across Europe, WTE facilities produced 56 terawatt-hours (TWh) of renewable energy in 2006, including 31 TWh of heat and 25 TWh of power.

A far different situation exists in the U.S., where public concern over pollutant emissions from incinerators has yet to dissipate, despite the stringent air quality control requirements imposed more than 15 years ago by the U.S. Environmental Protection Agency (EPA). No new MSW energy recovery plants have been constructed since the mid-1990s, and no commercial-scale MSW gasification or pyrolysis facilities have been built. The modest WTE capacity additions—largely of LFG facilities—have been motivated by federal air quality regulations and, more recently, state renewable portfolio standard (RPS) requirements, rather than by waste management policies.

According to data from the U.S. Energy Information Administration (EIA), load-serving WTE capacity exceeded 4.1 GW in 2008, but the amount running on MSW has declined slightly since 2003, falling to 2.2 GW. However, recent growth in LFG deployment helped to keep WTE’s share of nonhydro renewable capacity near 11%, third-largest behind wind and wood biomass.

As baseload, dispatchable units, WTE plants continue to play an important role in U.S. renewable energy generation, even accounting for the fact that capacity has stagnated and the EIA includes only the fraction of output attributable to biogenic sources such as green power. WTE technologies supplied 15.4 TWh of renewable energy to the grid in 2008, equivalent to 16% of nonhydro renewable generation, second only to wind. Of this total, MSW incinerators and fluidized bed combustion (FBC) units produced 7.2 TWh from biogenic fuels, which make up roughly 55% of the total U.S. waste stream by heat input. Counting output attributable to the combustion of plastics and other nonbiogenic materials, these plants produced roughly 13 TWh, pushing overall generation from WTE technologies above 20 TWh.

Independent power producers—among them waste management firms and municipalities—own the majority of load-serving WTE capacity, while more than half of the methane-rich fuel produced at U.S. landfills, agricultural operations, and wastewater treatment plants is applied to generate on-site heat and power.

Conventional incinerators typically collect MSW from a broad area, operate on must-run status, and offer availabilities exceeding 90%. LFG and digester gas facilities—collectively referred to as anaerobic-digestion-to-energy (ADTE) plants—are distributed resources sited, sized, and run according to fuel availability and production rate. Both MSW-derived fuels and digester gases may be cofired in fossil plants, but this may have operational and regulatory implications.

MSW projects have a unique attribute: As an alternative to landfilling, they typically charge a tipping fee to municipalities and other entities (Figure 1). This translates into a negative fuel cost—and a revenue source—that may help offset the high capital costs associated with fuel handling and environmental control systems and the high operations and maintenance (O&M) costs attributable to the variable composition, high moisture and ash content, high contaminant level, and low energy density of waste materials. ADTE plants also require a steady supply of no-cost fuel to justify the expense of collection, treatment, and conversion systems.

|

| 1. Turning trash into treasure. At waste treatment facilities, the tipping fees offset the operation, maintenance, labor, and capital costs of the facility along with the final disposal costs of any unusable residues. The fee can be charged per load, per ton, or per item, depending on the source and type of waste. This photo shows the Lee County waste-to-energy facility’s tipping floor, which is the designated receiving area where waste collection vehicles discharge their loads. Courtesy: HDR Inc. |

The economics of WTE plants are extremely site-specific, depending on tipping fees, MSW characteristics, environmental regulations, byproduct management practices, and many other factors. WTE installations often benefit from the investment and production tax credits granted to renewable energy sources. However, MSW plants sometimes are granted no, or partial, incentives because a significant percentage of their energy production results from the combustion of plastics and other nonbiogenic materials.

The economic viability of ADTE installations is strongly influenced by policy drivers. Policies requiring control of air pollutant and greenhouse gas emissions from landfills, agricultural operations, and wastewater treatment plants improve economics by reducing the incremental cost of adding generating capacity. Depending on site-specific circumstances, these projects also may yield revenue streams in the form of marketable renewable energy certificates and carbon credits.

Globally, more than 1 billion tons of post-recycling MSW continues to be disposed of in landfills each year, including more than 130 million tons in the U.S. While European, Asian, and other nations move forward with strong commitments to energy recovery, the U.S. faces mounting MSW management challenges, including the declining capacity of existing landfills, growing opposition to new disposal sites, high per-capita waste generation rates, low recycling rates, and air and water pollution concerns.

Electric Power Research Institute (EPRI) modeling studies of the U.S. electric sector performed using the National Electric System Simulator & Integrated Evaluator (NESSIE) project a fourfold increase in load-serving MSW capacity to almost 9 GW and a threefold expansion in load-serving LFG capacity to more than 4 GW over the next two decades under market-based climate policies.

Other countries that have not yet incorporated energy recovery as a key component in MSW management provide analogous deployment potential. China, for example, has indicated that WTE technologies will be employed to handle more than 30% of its MSW by 2030, a huge increase over current practice.

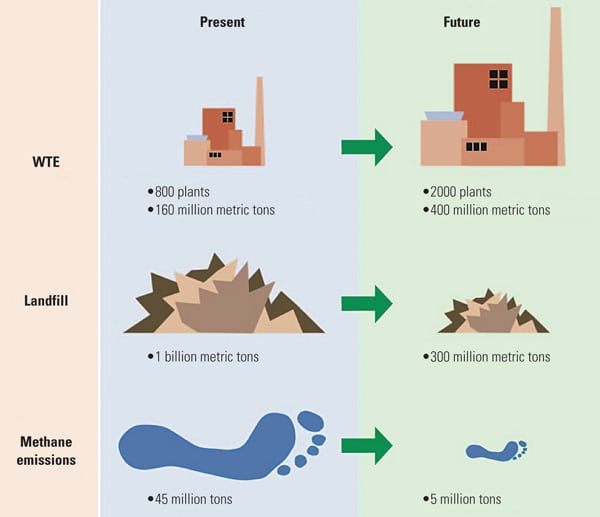

Figure 2 illustrates how a global transformation in MSW management—encompassing increases in recycling, energy recovery, and other practices to levels already being achieved in many countries—could lead to more than double current WTE capacity while decreasing the amount of MSW being landfilled by more than two-thirds (despite the growing waste volume associated with a growing population). If this transformation were to include expanded energy recovery from LFG, then a ninefold reduction in methane emissions also could be realized. To grow the role of WTE in meeting energy needs, advances are required in resource management, fuel processing, power generation systems, O&M techniques, and environmental controls. Supportive policies and incentives, and greater public acceptance, also are needed.

|

| 2. Benefits of expanding WTE deployment. Global adoption of integrated resource management strategies could dramatically increase deployment of incinerators and advanced conversion technologies. This development would reduce landfilling and associated emissions of methane, while expanded landfill gas capture and energy production could further reduce the carbon footprint of waste management practices. Source: Lauber & Themelis, 2010 |

Resource Management

Waste differs from other energy sources in that MSW management practices, along with producer and consumer behavior, determine the volume and characteristics of fuels suitable for conversion by individual technologies. Figure 3 displays a solid waste management hierarchy, with environmental efficacy declining from top to bottom.

|

| 3. Greening up MSW management. Incineration and advanced thermal conversion of the residual waste remaining after recycling and composting represent environmentally sound municipal solid waste (MSW) management options. Digestion-based waste-to-energy technology also may be deployed to extract useful energy from compostable materials and from landfill gas that is captured to reduce pollutant and greenhouse gas emissions. Source: EPRI |

Traditionally, integrated MSW management plans have focused on decreasing the amount of material that must be disposed of via incineration or landfilling. More recently, “zero waste” strategies have come to the fore, emphasizing prevention and materials recovery but also sharpening the focus on energy recovery as an approach for securing additional environmental benefits, including reductions in land use and emissions. In fact, the small physical footprint of incinerators and other WTE plants, relative to landfilling, is an important driver behind their widespread deployment for MSW disposal in heavily populated European and Asian countries.

Furthermore, although modern landfills are engineered and operated to avoid or minimize environmental releases of methane, volatile organic compounds, hazardous air pollutants, and leachate, control systems are nonexistent or inadequate at many locations, while even new landfills may capture as little as 60% of life-cycle methane emissions. Globally and in the U.S., landfills thus remain the second-largest anthropogenic source of methane, which has a global warming potential many times that of carbon dioxide (CO2). WTE plants avoid methane and leachate production, and flue gases generally are subject to stringent air quality controls.

On average, modern, electricity-only incinerators also yield roughly an order of magnitude more net energy per ton of MSW than LFG plants. Energy recovery from MSW thus is capable of displacing larger amounts of fossil generation. Additional emission reductions occur when materials removed from the incoming fuel feed and/or metals recovered from combustion byproducts are recycled. This avoids emissions attributable to the extraction and processing of virgin materials.

A frequently cited resource management concern is that WTE facilities may undermine recycling programs, but the European experience shows that countries with high energy recovery rates also exhibit higher-than-average recycling rates. In 2006, 41% of the MSW stream across Europe was recycled or composted, 19% was delivered to more than 400 WTE plants, and 40% was landfilled. In 2008, the U.S. recycling rate was 33%, 13% of MSW was delivered to a total of 87 WTE incinerators and FBC units, and 54% was landfilled, according to the EPA. Similarly, the post-recycling energy recovery rate is more than 30% across Europe, less than 20% for the U.S., and even lower in China and many other nations. By contrast, this rate ranges from 70% to 80% in Japan and exceeds 90% in Denmark and the Netherlands, highlighting the potential for increased WTE deployment.

Fuels and Processing Methods

As a fuel, MSW poses a number of challenges. It is produced on a distributed basis, and its composition is highly variable, including a mix of organic and inorganic constituents. Hazardous and toxic waste stream components pose health and safety risks. Low energy density and high moisture, chlorine, and ash content lead to handling, combustion, slagging and fouling, corrosion, and byproduct management issues.

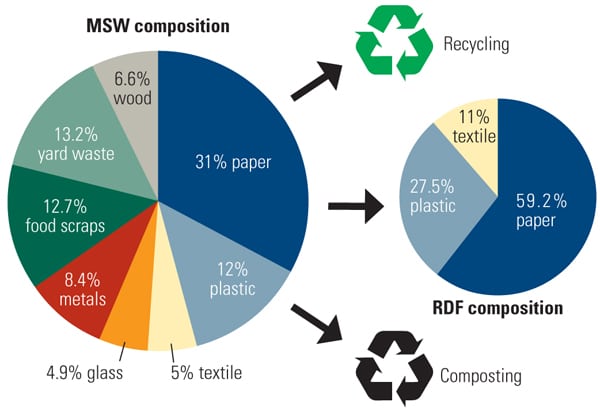

Lightly processed, post-recycling MSW received at mass-burn WTE plants has a heating value in the range of 4,500 to 5,500 Btu/lb. High-intensity processing yields refuse-derived fuel (RDF)—also known as solid recovered fuel—which is more amenable to firing in FBC units and advanced thermal conversion systems and offers the potential for high-rate cofiring in pulverized coal plants.

Mechanical, magnetic, thermal, biological, and other techniques may be applied to isolate and process combustible fractions. Residual waste—mainly a mixture of paper and plastics—is pulverized and dried to form a fluffy material of relatively uniform consistency with a heating value of roughly 5,500 to 6,500 Btu/lb (Figure 4). RDF may be packed as cubes or pellets for easy storage and transportation.

|

| 4. From refuse to electrons. When raw municipal solid waste (MSW) is transformed into refuse-derived fuel (RDF) that can be used to generate electricity, large amounts of inorganic and organic materials are recovered for recycling and composting. The end result is a higher-quality fuel with more uniform content and significantly improved handling and combustion performance. RDF also may be pelletized to improve transport. Sources: EPA and Scoullos et al., 2008 |

Processed engineered fuel (PEF) refers to higher-grade RDF produced from sorted and mechanically processed wastes, such as packaging materials and tires, and from custom blends of paper, plastic, and other materials.

The higher energy density, improved handling characteristics, and reduced moisture and ash content of derived fuels translate into lower heat rates and O&M costs. Of course, realizing these benefits has impacts, in that installing and operating fuel-processing systems at the plant site imposes energy and cost penalties. Centralized manufacturing of higher-grade fuels offers potential economies of scale, while source-based production creates opportunities to reduce hauling costs and facilitate long-distance trade. RPS eligibility remains an issue for individual fuel formulations.

For ADTE technologies, the digestion process relies on anaerobic bacteria that break down organic materials into sugars, acids, and then gases, leaving behind liquid and solid residues. Decomposition occurs over years to decades in landfills and days to weeks in purpose-built digesters.

Produced at atmospheric pressure and saturated with water, digester gas typically must be compressed, dehydrated, and treated. Depending on the fuel and power generation option, extensive pretreatment may be required to remove siloxane, hydrogen sulfide, and other constituents with potential to cause corrosion, erosion, environmental control, and odor problems. Further cleaning and purification are necessary to achieve the quality required for injection of pipeline-quality renewable fuel in natural gas delivery systems.

Generation Technologies

WTE technologies come in different forms, offer a variety of outputs, and are in various stages of development, but they have two common objectives: to both manage waste and generate energy. Conventional combustion-based processes transform solid wastes into heat for direct use or further conversion into steam and electricity, while advanced conversion processes convert solids into gaseous or liquid fuels offering broader utility. Figure 5 displays the status of a broad range of WTE technologies, showing the extent to which public-private investment is required to yield commercially mature systems.

|

| 5. Maturing at different rates. WTE technologies are at varying stages of development and commercial maturity, as shown by this Grubb curve. Source: EPRI |

Comparing the economic, energy, and environmental performance of individual WTE technologies on a consistent basis is extremely difficult. Traditionally, incineration and other options have been evaluated on the basis of $/ton of MSW disposed in comparison to the cost of landfilling or on their ability to meet the objectives of integrated resource management plans, rather than on the $/kW and $/MWh metrics commonly used in the power industry.

From an energy recovery perspective, producing hot water for direct use in district heating is the simplest and highest-efficiency approach for MSW, with a net level exceeding 60%. Generating steam for district or industrial process heating or CHP applications is somewhat less efficient, while cofiring RDF and PEF in coal plants further reduces conversion efficiency to around 30%. Steam-electric power generation in a dedicated incinerator or FBC plant offers low efficiency—around 20% or less—due primarily to fuel properties, boiler design and size, and heat losses, as well as reduced net power export due to parasitic energy consumption required by environmental control systems. MSW conversion processes yielding gaseous fuels suitable for firing in combustion turbines and combined-cycle plants offer potential for substantial gains in electricity production efficiency.

Conventional Thermal Conversion

Mass-burn incineration, the simplest and lowest-cost option for electricity production, also accounts for the overwhelming majority of installed WTE capacity.

FBC technology offers higher conversion efficiency and lower pollutant emissions, but its application has been constrained by the limited availability and higher cost of RDF. Higher-quality fuel is required to maintain stable combustion conditions in these systems because they have a much shorter residence time.

For both types of plants, steam serves a turbine-generator train, and power flows through a transmission-class substation onto the grid, as shown in Figure 6. Net electrical output is roughly 550 to 600 kWh/ton of MSW. Turbine exhaust is directed to a condenser for cooling, but in cogeneration applications heat may be extracted and water or steam fed to a distribution system for district or process heating. Conventional wet cooling systems may require significant amounts of water. Air-cooled condensers can reduce water consumption by up to 90% while imposing parasitic loads that increase generation costs.

|

| 6. Conventional and advanced thermal conversion technologies. Conventional mass-burn incinerators typically operate on as-received or lightly processed municipal solid waste and are based on mature steam-electric generation systems. In contrast, advanced thermal technologies require higher-quality refuse-derived fuel or processed engineered fuel and involve a multi-step process, whereby solid fuel is transformed into syngas that must be cooled, cleaned, and then fired to generate electricity. Source: EPRI |

Advanced Thermal Conversion

For advanced thermal conversion technologies, design goals are to increase materials recovery and recycling rates, improve the quality of recyclables, simplify flue gas cleanup, and reduce the quantity and improve the quality of solid byproducts that must be disposed of via landfill. There are three advanced thermal conversion processes of importance:

- Pyrolysis involves energy-assisted heating of MSW in the absence of oxygen within a range of about 400C to 800C. Byproducts include volatile liquids and syngas—with relative proportions determined by process temperature—plus a blend consisting primarily of metals that may be recycled and char that may be used for energy recovery or beneficial applications.

- Gasification involves heating of mixed MSW or derived fuels at temperatures exceeding 700C in the presence of sufficient oxygen to allow partial oxidation, but not enough for full combustion. This energy-assisted process yields a syngas mixture of hydrogen, carbon monoxide, water vapor, methane, and other constituents.

- Plasma arc gasification is a technology developed for hazardous waste incineration. It involves the use of a gasification reactor in combination with high-voltage electrodes that create a plasma torch. The torch operates at about 1,200C, well below the temperatures employed to destroy hazardous waste but sufficient to transform the complex gas mixture into a simpler syngas.

Once treated, MSW-derived syngas may be fired in internal combustion engines sized in 1-MW increments or, far less commonly, in steam-electric boilers. With additional processing, it may be used in combustion turbines or combined cycle units. Units generally are sized at 20 MW or less, and electric generation efficiencies of 25% to 40% are achievable. Energy recovery may yield recyclable slag, residual material that must be landfilled, or both.

Biological Conversion

Digestion relies on biological processes to produce gaseous fuels exhibiting considerable utility and energy density. Processes occurring within landfills generally are uncontrolled, while those occurring in enclosed plastic, concrete, or metal structures may be managed by altering feed characteristics and rates, controlling physical conditions, and making chemical and biological additions.

LFG is commonly collected and used to serve on-site needs for energy. At wastewater treatment plants, digester gas arising from processing of the solid fraction of domestic sewage traditionally has been fired for process heating, but a growing number of plants are using it for CHP applications. Manure from large-scale cattle, pig, and poultry operations increasingly is being employed to generate fuel for energy production consistent with some RPS mandates.

Digestion of biogenic MSW fractions is an emerging approach to solid waste management. For this application, mechanical pretreatment may be used to separate out residual recyclables and noncombustibles and isolate the organic materials to be introduced to the digester.

Reciprocating engines—the most commonly employed generation option for digester gas—may be installed in 1-MW increments to match the on-site fuel supply. Both smaller and larger engines are available. Small combustion turbines may be deployed in the range of 1 to 5 MW or at microturbine scale, while fuel cells may be employed for fuel meeting tight quality standards. Steam-electric and combined cycle plants are suited only to sites with fuel supplies capable of supporting central-station generation. In many cases, ADTE installations are backed by natural gas or propane firing capability to ensure consistent energy production.

Cofiring and Hybrid Cycles

MSW-derived solid fuels, syngas, and digester gas may be cofired in fossil plants, and hybrid cycles involving distinct waste and fossil fuel feeds are being explored. Depending on the fuel characteristics and policy environment, these approaches may provide options for reducing fuel costs and GHG emissions as well as generating renewable energy.

Proper fuel specifications are critical for successful MSW cofiring applications. Experience indicates that PEF with heating values in the range of 8,500 to 11,500 Btu/lb (wet weight basis) may successfully contribute up to 30% of the input energy in coal-fired boilers.

Renewable Gas

LFG, digester gas, and syngas may be upgraded and injected into natural gas networks for direct use in heating or transportation applications. LFG from the Fresh Kills Landfill in New York, for example, has been treated to increase methane concentrations, meet other pipeline-quality criteria, and feed the local gas distribution system for more than 30 years.

A number of utilities and agencies are exploring renewable gas production as an option for GHG mitigation and enhanced energy recovery because modern heating systems achieve efficiencies of 80% to 90% and higher—far above those achieved in power generation applications.

Operations and Maintenance

Modern WTE plants offer availabilities exceeding 90%, comparable to those of other baseload generating options. Sensor and control systems, operating environments, degradation mechanisms, and maintenance needs also are generally similar. Many of the O&M challenges unique to WTE capacity arise from the characteristics of MSW as a fuel source.

Difficulties in MSW handling and feeding increase labor and maintenance requirements and, along with variations in fuel quality, complicate process control in incinerators. High slagging and fouling rates necessitate frequent removal of ash deposits, while noncombustible materials and aggressive chemical conditions lead to accelerated rates of erosion and corrosion.

Environmental Controls

Modern incinerators have lower life-cycle pollutant and GHG emissions than landfilling. In general, WTE plants have output-based emission rates for conventional air pollutants roughly comparable to those of existing coal-fired capacity but higher than those of gas-fired units. On a per-MWh basis, overall CO2 emissions from incinerators typically exceed those of coal-fired plants due to high moisture content, other fuel properties, and low conversion efficiencies. However, the substantial percentage of these releases attributable to combustion of biogenic fuel fractions is commonly subtracted from the total under conventional life-cycle analysis frameworks.

Stack emissions and other releases from WTE plants generally are subject to stringent regulation, such as the maximum available control technology mandate under the Clean Air Act that required large U.S. incinerators to install dry flue gas desulfurization (FGD) scrubbers, fabric filter baghouses, activated carbon injection, selective noncatalytic reduction, and other measures by 2000. This largely has eliminated harmful emissions from existing MSW capacity, at the cost of increased parasitic energy consumption and higher O&M costs.

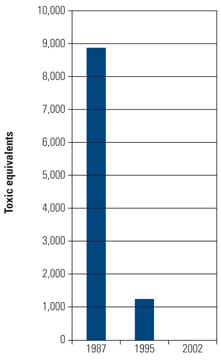

Figure 7 illustrates the dramatic reduction in dioxin and furan releases—from 8,877 toxic equivalents (TEQ) in 1987, when incinerators accounted for more than 60% of total U.S. airborne emissions, to 12 TEQ in 2002. This 99.9% decrease was complemented by absolute reductions in emissions of mercury, lead, cadmium, and hydrochloric acid of more than 90% and of sulfur dioxide and particulate matter by more than 85%. For some contaminants, source reduction has made important contributions. Many mercury-containing products have been phased out, and recycling programs in communities served by WTE facilities are keeping mercury out of the MSW stream.

|

| 7. Cutting out dioxins and furans. State-of-the-art environmental control systems have reduced dioxin and furan emissions from U.S. incinerators by 99.9% since the mid-1980s, and they allow these facilities to routinely comply with air quality standards tighter than those faced by coal-fired plants. Source: Psomopoulos et al., 2009 |

Capturing and recovering energy from LFG substantially reduces pollutant and GHG emissions, relative to landfilling. Limited data are available on air emissions associated with energy recovery from digester gas generated from wastewater, manure, MSW organics, and other biogenic wastes. A variety of pretreatment, combustion-based, and post-combustion technologies are available. Odor management measures include enclosures, filters and treatment methods at air intakes and exhausts, and negative pressure control.

Solid byproducts from MSW combustion and control processes include fly ash, bottom ash, slag, and FGD solids. Ferrous and nonferrous metals typically are extracted from bottom ash as recyclables, and the remaining ash then may be recycled as an aggregate material. Fly ash and FGD solids often contain relatively high concentrations of heavy metals and other contaminants. This may limit opportunities for beneficial reuse in concrete, fill, gypsum, and other applications and require disposal in a dedicated landfill, at significant cost.

Conventional treatment technologies are available for liquid wastes and thermal discharges generated during fuel storage, dewatering, steam-electric conversion, environmental control, and cooling operations associated with WTE capacity.

Future Directions in the Development of WTE Technologies

Many European and Asian nations have high energy recovery rates, while mature WTE technologies have experienced relatively modest application in the U.S. and many other countries. To expand deployment in the U.S. and elsewhere, common misconceptions regarding the environmental performance of WTE technologies must be eliminated, and decision-makers must treat post-recycling MSW as an asset for energy recovery, emission reduction, and baseload renewable energy production rather than as a liability for disposal.

In addition, the costs and risks of existing and emerging WTE options must be reduced through investments in research, development, and demonstration (RD&D) to improve cost-performance characteristics and through consistent policy and market frameworks that account for their attributes as renewable energy and climate mitigation options.

As shown in Figure 8, most U.S. regions continue to landfill much more than 50% of their solid waste. Almost half of the existing MSW-firing plants are sited in densely populated northeast states, where landfill space is at a premium. Since 1996, no new incinerators have been deployed in the U.S., leading to an increase in intrastate MSW transport from sending areas lacking landfill capacity to more rural receiving areas. Despite the fact that long-distance hauling and landfilling result in higher levels of pollutant and GHG emissions than would energy recovery from a nearby WTE facility, this trend may continue as existing disposal sites are closed and challenges associated with permitting new landfills in developed areas grow.

|

| 8. Untapped potential. Given the very low energy recovery rates and high landfilling rates in many regions of the country, the U.S. has many promising prospects for successful WTE deployment. Sources: Michaels, 2007; Simmons et al., 2006 |

Countering this trend is the recent expansion of a WTE plant in Lee County, Fla. (Figures 9 and 10), where generating capacity was augmented from 40 MW to 60 MW to handle the increasing MSW volume from Ft. Myers and nearby communities. Efforts to expand existing facilities are under way elsewhere, and new plants are being considered across the country. However, a number of U.S. states maintain bans on new MSW incinerators and are considering extending these bans to include advanced WTE technologies such as gasification and pyrolysis.

|

| 9. Leading the way. The Lee County waste-to-energy (WTE) and recovered material processing plant, one of the most advanced solid waste management systems in the U.S., burns waste at more than 1,800F. The plant is equipped with extensive air-pollution control systems, such as the scrubber shown in the photo. The Lee County WTE plant is the first U.S. plant built with a permanent activated carbon injection system for controlling mercury emissions. Courtesy: HDR Inc. |

|

| 10. Once is not enough. Adding an additional layer of sustainability, the Lee County WTE plant operates as a zero-discharge facility. The clarifier at the plant is used to treat recycled wastewater from a nearby municipal wastewater treatment plant. Courtesy: HDR Inc. |

Relative to landfilling, energy recovery offers much lower GHG emissions, requires much less land, and boosts recycling rates. Stringent regulations, advanced control technologies, and other measures hold pollutant emissions from modern incinerators below the permit limits established to protect environmental and human health. Handling practices—such as using rail rather than truck transport, employing covered containers, and unloading MSW inside buildings with negative pressure control—help address noise, litter, and odor concerns. WTE technologies deployed at landfills, treatment plants, and farms offer an advantage in that they may be seen as part of an ongoing municipal or agricultural operation.

Comprehensive life-cycle analyses evaluating energy recovery within waste management, energy supply, and climate mitigation contexts are needed to document the benefits of WTE technologies, while proactive communication with decision-makers, stakeholder groups, and the public is required to address concerns and increase acceptance for individual projects as elements within integrated resource management strategies. Science-based information and educational outreach also are necessary to help ensure that WTE options are eligible for the investment and production incentives granted to renewable energy sources and are designated as qualifying technologies under RPS mandates and other directives.

Cost reduction and further improvement in environmental performance represent additional RD&D priorities. At present, MSW incinerators are much more costly to build and operate than coal-fired steam electric capacity and other baseload generation, and most WTE plants are economically viable only because their fuel provides a source of revenue in the form of tipping fees.

New source separation and MSW processing technologies are needed to remove potentially harmful constituents and to produce derived and engineered fuels offering improved handling characteristics, increased energy density, and decreased moisture and ash content, and reduced emissions of pollutants and GHGs. These advances would reduce the capital investment required for fuel feed and environmental control systems, as well as lower heat rates and O&M costs for incinerators. In addition, they would facilitate long-distance fuel transport, potentially leading to the siting and construction of larger, more cost-efficient WTE facilities in rural areas. Improved fuels also would enable high-rate MSW cofiring in coal-fired plants, a potentially low-cost approach for reducing carbon emissions from existing capacity while generating renewable energy.

To support deployment of advanced conversion processes and hybrid plant concepts, successful commercial-scale demonstrations are needed to confirm the ability of individual technologies to handle large amounts of waste on a reliable basis, in an environmentally sound manner, over an extended period.

Current EPRI projects address several key areas for growing the role of WTE technologies in meeting U.S. needs for clean, affordable, reliable, and sustainably produced electricity. EPRI plans to continue collaborative work with utilities, agencies, and other stakeholders to identify and pursue near-, mid-, and long-term RD&D needs and opportunities.

— Stan Rosinski ([email protected]) is program manager of Renewable Generation at the Electric Power Research Institute Inc. (EPRI). To access EPRI’s full “Waste-to-Energy Technology” white paper, go to http://tinyurl.com/7jc4sxs.