TOP PLANTS: LCEC Generation Plant, Lovington, New Mexico

|

| Courtesy: Burns & McDonnell |

Faced with the need to begin generating its own power after decades of relying on larger regional suppliers, and impending renewable portfolio standard requirements, the Lea County Electrical Cooperative had to get creative. Its choice of a highly flexible gas-fired engine plant that will work together with a nearby wind farm makes this a POWER Top Plant.

The Lea County Electrical Cooperative (LCEC) serves six rural counties in southeastern New Mexico and western Texas. Incorporated in 1949, the cooperative has spent most of its existence trying to stay ahead of its members’ electricity demands. Though it initially operated a diesel generating plant and a gas-fired steam plant, the increasing costs of fuel and generation led it to shut these down in 1983 and purchase all of its power from Amarillo-based Southwestern Public Service (SPS, now part of Xcel Energy), which supplies power to much of New Mexico and west Texas.

In the early 2000s, with the SPS contract due to expire in 2015, the LCEC board began exploring options for the future of its power supply. Xcel/SPS had decided not to invest in sufficient new generation to meet LCEC’s projections for future demand, so the board decided that the best way to meet growth and resource requirements for its retail customers was to terminate the cooperative’s wholesale contracts. In 2010, LCEC negotiated a new agreement with SPS that would require it to be completely off the SPS grid by 2026.

But meeting its demand meant more than just building a new plant. LCEC is subject to a state-mandated renewable portfolio standard that requires 5% of its energy sales to be generated from renewable energy in 2015, rising to 20% in 2020.

After making the break with SPS, LCEC announced plans to build an approximately 40-MW gas-fired engine plant in Lovington, N.M., that would be a first step in once again generating its own electricity. This would integrate into a nearby wind farm that was also in the planning stages. Said Gary L. Hurse, LCEC general manager, the cooperative went this direction because “the ability to integrate fossil fuel generation with a renewable wind project is the future resource mix for the electric utility industry.”

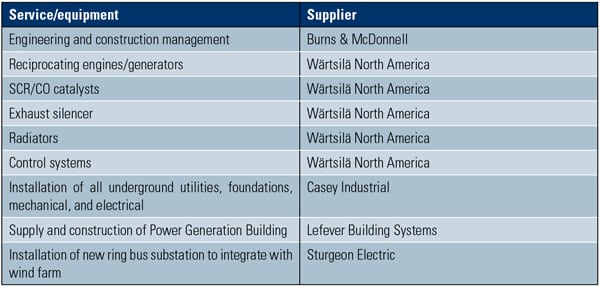

Burns & McDonnell was chosen to oversee engineering and construction of the project, and the contract for the plant was awarded to Finnish manufacturer Wärtsilä. Wärtsilä is a leading supplier of gas-fired engine power plants, having delivered a number of similar projects around the world. Just as important, the fast-starting, fast-ramping plant would provide the best support for power from the wind turbines. The full vendor list is given in Table 1.

|

| Table 1. Major contractors and equipment suppliers to LCEC Generation Plant. Source: Burns & McDonnell |

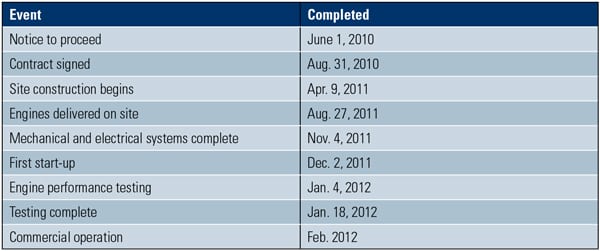

The contract for the engines was signed in August 2010, and construction began in April 2011. The site was prepared and foundations laid over the next two months, and building construction began in June. All ancillary equipment including the radiators, exhaust system, combined auxiliary module, exhaust gas modules, maintenance water tank, and starting air compressors were set in place in preparation for arrival of the engines from Finland.

After a more than 6,000-mile journey by ship, rail, and truck, the engines were delivered to the site in late August and early September. All mechanical and electrical systems were finished in November. Testing was conducted in December, and the plant was fully operational on January 4, 2012—five months ahead of schedule and after a mere nine months for the combined construction, installation, and commissioning. Key milestones are given in Table 2.

|

| Table 2. Key milestones for the LCEC Generation project. Source: Burns & McDonnell |

As completed, the LCEC Generation plant comprises five 20V34SG Wärtsilä gas reciprocating engines, each rated at 9.34 MW (Figure 1). At full power, the plant can provide 46.7 MW of intermediate and peaking generation. It employs a selective catalytic reduction emission system that reduces NOx by 96% and carbon monoxide by 94%.

|

| 1. Ready to rumble. The five Wärtsilä gas-fired engines provide LCEC with a highly flexible, highly responsive generation resource. Courtesy: Burns & McDonnell |

The LCEC Generation Plant is the first step in LCEC’s plans. This facility provides direct backup and load following for the 27-MW wind-powered generating installation that was just completed by Exelon. This wind farm consists of 13 Suzlon S97 2.1-MW turbines. It is currently undergoing testing and went online in early July.

The LCEC plant has the ability to reach full output in 5 minutes, and 25% power in 2 minutes. It can maintain constant performance over varying ambient conditions and responds rapidly to varying grid conditions. The plant can operate efficiently at low loads, providing a “spinning reserve” for the system. Wärtsilä rates the LCEC plant’s overall efficiency at approximately 45%.

“This will be the first time in the United States that these high-efficiency Wärtsilä gensets will be used in tandem with wind energy,” Hurse said at the ribbon-cutting ceremony. “We’re looking forward to providing our members with the clean, renewable energy they want along with the reliability that these new generators will ensure.”

Brian Elwell, the project manager for Burns & McDonnell, was equally effusive about the final result. “We hear every day that we need to develop an energy strategy that incorporates an ‘all the above’ strategy. LCEC did more than just talk about it. They aggressively pursued matching the latest in natural gas technology with a renewable wind project. I am positive that this will be a great success for LCEC.”

— Thomas W. Overton is POWER’s gas technology editor.