Optimizing the Life-Cycle Cost of Human Capital

Is it possible to develop a business model whereby an economic dip can be used to a market advantage? One client uses a sports analogy to describe this opportunity: "We are between seasons, and we have an opportunity to recruit and retool our team for the future." This just might be the right time to retool your human resources processes to avoid past hiring mistakes and adopt new hiring practices that will maximize the life-cycle value of your company’s human capital.

The abrupt and unexpected global economic downturn has forced many industrial companies to make gut-wrenching decisions about how to manage their labor costs. In almost every business sector, companies have been forced to curtail production, close plants, and reduce staff just to survive. Such decisions obviously affect plant personnel, but the effects ripple throughout the community where the plant is located.

After making the decision to reduce staff, a company faces additional financial consequences: perhaps hundreds of millions of dollars in cash payments for severance packages and voluntary early retirement program pools for key management positions.

Loss of key employees further reduces the organization’s overall performance because severance packages usually target the most senior and experienced personnel. The spiral continues because loss of these key employees substantially handicaps a company’s ability to respond to the inevitable upturn in business.

Turn a Negative into a Positive

When companies hire employees, it often is simply to get work done. Little thought is given to the life-cycle cost of that decision. Many companies hire employees on the basis of the hourly wage plus some benefit cost multiplier. However, the total life-cycle cost of a position should be evaluated prior to making hiring decisions. For example, the actual cost of hiring and outfitting a new mid-level manager for one company was 50% higher than the employee’s $60,000 annual salary. At a 4% inflation rate, the average total fixed cost of hiring and keeping this employee for 30 years could easily exceed $5,000,000.

So how can companies optimize the life-cycle cost of human capital? These nine steps outline a process with proven results:

-

Identify your company’s true core competencies.

-

Evaluate all jobs against the core competency criteria.

-

Analyze the company’s noncore job performance excellence.

-

Benchmark current noncore jobs for performance.

-

Develop a business case for outsourced job function candidates.

-

Select a contracting strategy that will deliver continuously improved performance and results.

-

Select a qualified contractor.

-

Develop contractor key performance indicators (KPIs) that will allow you to objectively measure results and performance.

-

Implement the performance-based contract.

To minimize the fixed labor cost, companies should evaluate where they need to invest in labor to create and maintain a competitive advantage for their business and then determine what activities can be performed more efficiently by someone outside of the company.

1. Identify Your Company’s True Core Competencies

A best practice is to hire only employees who contribute to a business’s core competencies. The problem we often see while dealing with hundreds of clients is that you can emotionally convince yourself that almost any job is core to your business. To avoid this problem, a company’s strategic leadership team should establish objective criteria to determine what is core to the current and future business.

Here is an example of a simple test using objective criteria that can be used to determine if activities or job positions are core to a business:

-

They increase market size or access to new markets.

-

They provide a unique or significant contribution to the end product value.

-

They provide a barrier that is expensive or hard for competitors to imitate or recreate.

If an activity or job function does not provide any of these benefits, it should be considered noncore and be a candidate for outsourcing.

Outsourcing noncore functions is a strategic decision that has significant impacts on short- and long-term company objectives. Just because job functions are noncore does not mean they are unimportant. In most cases it is just the opposite.

For example, putting in a new manufacturing line, maintaining production equipment, and performing root cause failure analysis are all critical noncore jobs. Because these functions are critical, doesn’t it make sense to hire experts for whom this type of work is a core competency? This concept is almost never fully understood and is the reason for most outsourcing failures. Remember, noncore jobs do not contribute to:

-

Increasing market size or access to new markets.

-

Providing a unique or significant contribution to the end product value.

-

Providing a barrier that is expensive or hard for competitors to imitate or recreate (or whatever criteria you develop as core to your business).

My experience is that most indirect-cost job functions do not past this test. However, many companies dilute their ability to invest in core business functions because they are paying too much for noncore fixed cost jobs.

2. Evaluate All Jobs Against the Core Competency Criteria

In addition to the test in step one, another way to determine if labor costs are excessively high is to evaluate your capability to deliver at best practice levels. Many companies have invested for years in developing capability in noncore business activities and functions, and eventually they have become quite competent in some or many of those functions.

A simple way to determine the balance of noncore and core business activities is to evaluate whether a company has the capability to deliver world-class services at the lowest cost by doing the following. List your core competencies — such as engineering, contractor management, and maintenance management — down the left side of a table. Add three more columns, and given them the following headers to identify the source of the competency: Owner, Service Partner, and Original Equipment Manufacturer/Vendor. Rank each core competency on a 1 to 5 scale with 5 representing "world-class performance," 1 representing "industry laggard," and 3 representing the "industry norm." Repeat the exercise with noncore competencies.

If the scores for noncore functions are equal to or greater than those for core function, you are overinvesting in noncore job functions and underinvesting in your core business.

3. Analyze the Company’s Noncore Job Performance Excellence

Simply possessing a capability is only one factor to consider. Many companies have pockets of excellence but cannot deploy that capability throughout the enterprise. The same approach as used above can help determine where the ability to deliver lowest-cost services throughout an enterprise resides.

Create another table and list owner competencies down one column, as before. Then title three more columns: Methods and Procedures, Relevant Experience, and Bench Strength. Rate each owner competency from 1 to 5, with 5 for "ready for manufacturing enterprise rollout," 1 for "industry laggard," and 3 for a "pocket of excellence but needs development or investment." Repeat the exercise with your service partner’s competencies.

Owners should have exceptionally high marks in job functions that are core to their business, while service providers should have exceptionally high scores for job functions that are their core competencies. If not, you may need to reevaluate how essential but noncore competencies are managed in your organization.

4. Benchmark Current Noncore Jobs for Performance

Benchmarking in some of the highest performing companies in the world has shown that the best opportunities to optimize the cost of human capital and company performance are mostly in the indirect or noncore part of the business. Because of the nature of fixed indirect cost and noncore services, companies are usually hesitant about investing too much money in these areas, and rightly so. The result is typically untrained personnel and high turnover, inefficient job performance, and excessive cost.

Even when they realize this, many companies are unconvinced that outsourcing to service companies that do have specific functions as a core competency is the best way to lower the cost of human capital. Therefore, a more objective approach should be initiated to quantify the opportunities in terms of dollars.

5. Develop a Business Case for Outsourcing Job Functions

A cost analysis should also be performed to determine the baseline for noncore job performance cost. The performance benchmark data and cost baselines are then integrated with production performance costs and losses to calculate an economic gap analysis. The gap analysis will act as a roadmap to determine the value of improved indirect cost optimization for each category of cost and to prioritize optimization efforts.

Once a proper root cause analysis has been performed on all major performance gaps, an improvement plan can be put in place to calculate the benefits of improved performance and to optimize indirect costs. The options at this point are to determine if investments to remedy deficiencies provide the best return for the money or if there is an opportunity to team with a service provider that has the best practices in a given function to optimize business performance.

6. Select a Contracting Strategy That Will Deliver Continuously Improved Performance and Results

If you determine that outsourcing might be the best way to enhance business performance, you should determine what should be outsourced, select the best contractor to meet your needs, and determine the type of contract you should have with your contractor.

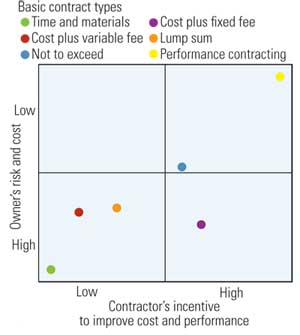

An effective performance contract — one in which the contractor is rewarded based on achieving specific owner business targets — motivates contractors to help achieve the owner’s business goals and objectives through financial incentives. Often, the incentives flow down through the contractor’s organization to reward employees at all levels (Figure 1).

1. Balancing act. Consider different contracting strategies when selecting a contractor that will partner with you to optimize business performance, lower life-cycle labor costs, and properly distribute the project’s financial risk. Source: Fluor Corp.

7. Select a Qualified Contractor

Selecting the right contractor maximizes the benefits of outsourcing while eliminating or minimizing the need to self-perform a task. Leveraging contractor expertise has many benefits, including access to highly skilled, scarce resources.

Other benefits justifying decisions to outsource plant services using a performance contract typically include these:

-

Variable rather than fixed labor costs

-

Increased labor flexibility

-

Improved productivity

-

Access to a broader range of skills and expertise

-

Broader, more effective knowledge base

-

Reduced cost for training processes and management systems

-

Improved focus of internal resources on core competencies

Another problem that companies face is the very concept of outsourcing. For every success story, there are many horror stories about losing jobs, cutting people’s salaries, poor performance, loss of control, and more. Most outsourcing failures are a result of poor management decisions, work process, and misalignment of expectations between the owner and the contractor.

Too often, once the decision to outsource is made, the process is turned over to the procurement department, which puts the outsourcing contract out for lowest price bid — like a commodity. Some companies even go as far as putting the bid on reverse auction to further lower the price. However, selecting a service provider with the necessary knowledge, skills, business processes, tools, and methodologies does not lend itself to typical procurement practices such as issuing a request for proposal and awarding the scope of work to the lowest bidder.

A company needs to perform a thorough evaluation of a contractor’s ability to substantially lower life-cycle cost. A contractor that will have a significant impact on an owner’s business needs to be selected much as you’d choose a business partner. In fact, that is exactly what a strategic performance-based contractor will be: a partner who shares in the business risks and in the business results or profits.

The owner’s due diligence on a strategic contractor should include:

-

History of performance contracting with similar projects

-

References from past, recent, and current clients

-

Documented methods and systems

-

World-class safety record

-

Proven computer-based training programs

-

Change management processes and expertise

-

Subject matter expert resources

-

Business risk management process

-

Executive management commitment

-

Financial stability

-

Strong human resources/industrial relations resources and experience

8. Develop Contractor Key Performance Indicators

Strategic performance contracts require a different contracting strategy. Strategic scopes of work should be directly tied to business results with KPIs. To impact business results, scopes of work typically fall into three categories for a process or manufacturing facility: increasing revenue, lowering operating cost, and maximizing assets.

Increasing revenue:

-

Plant availability

-

Quality throughput

Lowering operating cost:

-

Material cost

-

Inventory cost — obsolescence and turnover

-

Expediting cost

-

Contracting/compliance cost

-

Labor cost

-

Rework cost

Maximizing assets:

-

Improve production plan adherence

-

Increase return on production assets

-

Improve efficiency per labor hour

The key to successful performance contracting is to understand the net effect, impact, or benefit that a contracted scope of work will have on long-term business results. Many times, assets are mined, maintenance is deferred, and key people with essential knowledge and skills are let go or forced to leave in order to deliver short-term benefits. The cost to restore the asset, repair collateral damage because of deferred maintenance, and/or replace knowledge and skills can result in adding back exponential cost to stabilize production, quality, and safety in an operating facility.

The owner must be able to balance the long-term effect of any benefits received from a performance-based contract. Performance contracts should play a part in a company’s long-term strategy and should be structured for a minimum of three to five years to ensure that the contractor delivers sustainable business results that do not undermine the company’s future profits.

9. Implement the Performance Contract

Once the contractor has been selected and the KPIs and performance metrics have been mutually agreed upon, the execution of a performance contract is typically implemented in phases. The three most common phases are:

-

Mobilization

-

Implementation

-

Steady-state continuous improvement

Mobilization is the process of getting the contractor’s and owner’s team into place and is critical to project success. The team should plan and allow for the proper mobilization of the right resources. The owner needs to thoroughly interview the contractor’s essential on-site management team. Although they are not part of the owner’s organization, the owner will ultimately rely on them to deliver the expected results of the agreement. The owner needs to be reasonably sure that the contractor’s team will work well with the company’s. On the flip side, the owner needs to be responsive if the contractor questions the fit of someone on the company’s team. One bad apple can spoil the whole bunch, regardless of who owns the apple.

Implementation is the process of setting up best practices that germinate the improvement process. Almost all owners underestimate the effort and resources that are required to change the way a company does business — and may have done business for more than 50 years. People, culture, methodologies, processes, procedures, and protocol are all affected by change. On a major project, expect the implementation process to take six months to a year or more. Even then, change will not stop; people will become accustomed to the idea that continuous improvement depends on constant change.

Steady-state continuous improvement is the mature phase of a project, when the dividends of performance contracting start to pay off. In the early stages of implementation, low-hanging fruit savings and improvements are realized. However, it is during the steady-state continuous improvement phase that sustainable step changes will occur.

Many top-performing companies have implemented strategic performance contracting as a long-term competitive strategy. In addition, many of these owners are leveraging the contractor’s resources and expertise to deliver additional benefits through such programs as Systematic Failure Elimination and Profit-Centered Maintenance while lowering their cost of human capital.

—Bradley K. Cunic ([email protected]) is an executive director of Fluor Corp.