Analysts say 16.3 zettabytes of data were created in the past year, and experts say 180 zettabytes will be created worldwide in 2025. The energy industry’s contribution to that total is substantial. Gas turbines generate 30 gigabytes each day. Wind turbines generate 200 GB. The oil and gas industry generates 2 terabytes each day. And those numbers will continue to grow.

The energy industry has undergone more change in the last five years than in the previous century.

And while energy producers have been slower than other industries to adopt digital technologies as part of their overall business strategy there are incremental changes that can be made to make substantial gains quickly. Data has become one of the world’s most valuable resources and energy companies are sitting on mountains of it. The key is to unlock the potential to provide actionable insights to drive growth.

Data has become one of the world’s most valuable resources and energy companies are sitting on mountains of it.

Companies know they must embrace digitalization, reshaping their business to be more sustainable and efficient, all while enhancing the customer experience. This means moving forward, making critical business decisions to capture market trends, developing strategies to manage risks and costs across all divisions while maximizing assets. The business world of tomorrow is about digitalization, creating a bridge between real and virtual worlds. Digitalization is about turning that data into value for your business. And companies don’t have to do that alone.

Siemens has developed innovative tools to help businesses harness the power of this digital transformation. Its digitalization products and services can strengthen a business by improving reliability while maintaining and potentially increasing profitability. Digitalization is a critical enabler of positive change, for more efficiency, sustainability, and security. Siemens works with businesses to chart a course to overcome challenges, using technology to be stronger and better on the road to success both now and in the future.

Analysts say 16.3 zettabytes of data were created in the past year, and experts say 180 zettabytes will be created worldwide in 2025. The energy industry’s contribution to that total is substantial. Gas turbines generate 30 gigabytes each day. Wind turbines generate 200 GB. The oil and gas industry generates 2 terabytes each day. And those numbers will continue to grow.

The energy industry is in the midst of upheaval. The traditional role of fossil fuel-powered facilities is being transformed. The power generation mix includes more and more renewable resources, and the advent of distributed generation has changed the business model for many local utilities.

Worldwide installations of renewable energy, such as solar and wind, are expected to reach 191 GW by 2020—more than double the level of a decade ago—and to rise to 300 GW by 2030. Renewables are projected to make up 87% of new power installations by 2030, compared to just 55% in 2010, and 65% of distributed power generation is predicted to come from decentralized sources by 2030, nearly double that of 2010. By 2030, 35% of all generation capacity may be customer-owned.

Many power plants are evolving into renewable load-following units, called upon to quickly bring large amounts of electricity onto the grid when the wind stops or the sun fades. The frequent starts and stops required of today’s turbines can bring more unplanned downtime and provide a challenge to maintenance and upkeep.

Power generators also are faced with incorporating energy storage into the generation mix. The annual U.S. energy storage market is expected to reach 1.7 GW by 2020, with a value of $2.5 billion. IHS, which provides information and analysis to businesses worldwide, projects the energy storage market will top an annual installation size of 40 GW by 2022, an exponential increase from an initial installed capacity of just 0.34 GW in 2012-2013. Utilities are looking for energy storage solutions, and some states and countries are mandating that higher percentages of storage be utilized during periods of peak electricity demand. The Energy Storage Association, in its recent U.S. Energy Storage Monitor 2017 Year-in-Review, says that 1,000 megawatt hours were deployed between 2013 and 2017—and more than 1,200 megawatt hours of energy storage will be deployed in 2018 alone, a nearly 300% increase over last year. That’s why Siemens and AES created a joint venture, Fluence, to transform the next generation of energy storage.

The rise of distributed generation and distributed energy resources (DERs), wider adoption of combined heat and power (CHP), and the growth of microgrids also are challenging the traditional grid. Siemens is involved with helping energy providers deal with grid integration of renewables, developing systems to deal with evolving policies and regulation, along with fiscal constraints.

For utilities, it means the integration of cloud services, which today make up half of the IT portfolio for more than 60% of these businesses. Utilities are investing more than 25% of their IT budgets on integrating new technologies with legacy enterprise systems. At least 45% of utilities’ new investment in analytics will be geared toward operations and maintenance of power plant and network infrastructure. Some 60% of utilities will focus on transitioning enterprise mobility, looking to capitalize on the increased use of digital devices by consumers who want information while on the go. It’s all part of the development of smart systems, allowing utilities to improve their service and manage their costs.

The transformation of the energy industry is apparent in the marketplace, with the growth of decentralized energy and the push for cleaner energy sources. Customers require increased flexibility and smarter energy solutions, turning the promise of big data into actionable resources. More than half of the world’s data was created in the past year, but less than one-half of 1% was analyzed or used, which underscores the enormous potential of how companies can reap the rewards of digitalization tools and expertise like Siemens’.

It’s taking originally unstructured data and creating value, using the knowledge of analytics, devices, and applications, as well as the market environment, to optimize results—whether you’re running gas turbines, solar arrays, wind farms, or thermal power plants.

Every organization must find the right balance between boosting profitability when the market is ripe, and curtailing losses when the unexpected descends suddenly. Energy companies are no different. To stay ahead of the curve, companies should look at many scenarios, based on real-time digital data feeds. This enables a thorough view of best and worst cases, and anything in between, to help with decision-making and to test strategies. Power generators are always looking for sensible cost-saving actions; the digital transformation presents a clearer picture of where those savings can be achieved.

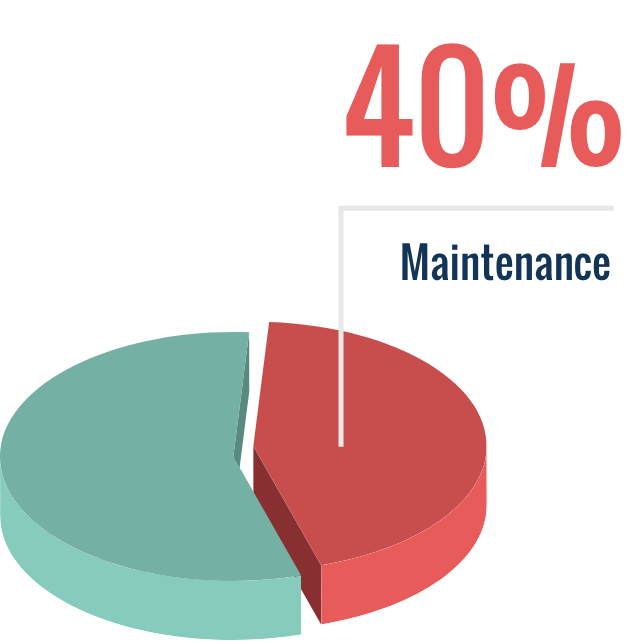

Maintenance can account for as much as 40% of operating costs for energy companies, and those costs can increase with unplanned downtime and money tied up in carrying replacement parts. By leveraging the power of the digital transformation, businesses can identify areas to reduce unplanned downtime, and heighten predictive maintenance accuracy through transparency and advanced analytics. By knowing and understanding the exact condition of your operating assets, it is possible to reduce the need for inventory by ordering a part and conducting maintenance only when necessary.

Digitalization also can increase availability and performance. By connecting OT and IT, it’s possible to integrate and unify the management technology, processes, and methods used to manage physical energy systems—the OT—and business management systems—the IT. This approach is the norm within most competitive energy companies and facilities, and has led to significant gains in efficiency, speed, and effective control. Digitization and virtualization also enables companies to centralize key aspects of system and process management, or outsource services, such as remote analytics support. This makes it possible to do more, to a higher standard. This delivers cost advantages to all operators, and those managing large fleets can benefit most. With the support of remote monitoring and diagnostics from Siemens, a specialized service provider with fleet-wide experience, companies can further increase the availability and performance of their equipment.

The growth in connectivity enables systems of every kind to become “smarter”, better at self-diagnosis and reporting. This can often deliver a true step-change in operational efficiency. Specialist capabilities can potentially be deployed from remote locations, while large-scale, open data flows, supported by customized analytic tools, enable management to become far more proactive than before. In order to stay competitive, to meet ever more demanding commercial terms and regulatory requirements, it is not simply desirable but essential to build a more flexible and fast-moving, fast-responding business.

The new energy landscape does not come without risk. Siemens constantly works to stem the tide of increasing cybersecurity threats, with a goal of keeping critical infrastructure safe and secure. Power generation companies must invest in high-performing cybersecurity solutions to survive and prosper in a more connected and competitive world. Having credible policies for security, continuity, and performance auditing for OT and IT systems can mean the difference between having a competitive advantage or falling behind. Siemens offers a step-by-step approach to cybersecurity, a four-part process built on deep engineering and OT knowledge, backed by global resources and focused on continuous evolution. Siemens has developed partnerships with PAS, Tenable and Darktrace to provide a robust cyber offering to the energy industry.

Experts from Siemens can evaluate organizations, building a complete picture of the asset and organizational landscape, providing clear visibility and identifying areas of concern for all systems, both IT and OT. The company develops an intervention and implementation plan, dealing with urgent issues first, reflecting customer priorities and sound plant maintenance strategies. Siemens’ OT know-how delivers tailored solutions to ensure availability, engineer out weaknesses, and make the entire landscape impenetrable.

Siemens executes repeated, rigorous, comprehensive testing of components, systems, and connections, together with data and ecosystem integrity. Then it maintains security with a long-term, systematic approach to defense, constantly updated and refreshed, based on continuous vigilance. This enables companies to maximize the potential of their expertise through remote management.

As core operational systems become accessible from the internet, the integrity of those systems can be undermined, and when industrial control systems and their respective digital infrastructures are threatened, it can affect not only the companies concerned but also have a broader effect on the economy. Building enhanced cyber strategies is an immediate priority, certainly for power generators whose control systems manage production of nuclear, fossil fuel-based, and renewable energy. Siemens provides organizations with a trusted security partner, there with around-the-clock monitoring and immediate alerts for critical and sensitive systems. The company can deploy cutting-edge technologies, all designed with the knowledge that keeping systems safe today is a necessity for any industry. It provides a charter of trust for a secure digital world.

Today’s digital landscape provides a view across an entire enterprise. Siemens can provide the tools to help customers manage products and services for the complete spectrum of their businesses. The company’s drone technology is being used for site inspections, freeing personnel to be deployed in other areas and reducing operational and maintenance costs. Siemens’ systematic inspection systems using drones and 3-D image analysis can monitor pipelines, large industrial facilities, and pylons in high-voltage electrical distribution systems. Its drones and sophisticated sensors can “see” better than a human, replacing expensive helicopters thanks to their maneuverability, small size, and low costs, opening the door to new levels of security and efficiency for a variety of infrastructures.

The challenges of today’s market, with increased demand for energy, next-generation and disruptive technologies, and competing new business models, mean utilities need to effectively manage their legacy systems as they improve their customer focus. Siemens has developed a modular suite of applications that can be rolled out into preexisting power-generating infrastructure independent of the original manufacturers. For example, with Fleet Center Solutions customers gain full transparency, not just on the machine or plant level, but across an entire fleet. This can allow for benefits such as better risk management, optimal asset deployment—both cost- and revenue-focused—and improved workflows. Siemens Fleet Center Solutions turn technical data into actionable information. Tools can be individually adapted to specific requirements, such as asset diagnostics, performance monitoring, or optimized operations, opening new horizons for utilities to manage and market all their assets.

Siemens’ digital solutions provide answers for disruptive market changes by adding agility to a business. Digital transformation changes the way work gets done, with new business models and new opportunities. It can deliver on the promise of big data, shifting the emphasis from data collection to a focus on deriving meaningful insights and outcomes from data. It’s a paradigm shift, in which interconnectedness applies not only to assets, but also to the ability to work together in partnership.