Leveraging Fuel Flexibility for Coal Power Plant Survival

Improving fuel flexibility at coal power plants is typically considered a way to reduce generating costs and increase reliability. But in the uncertain regulatory and economic future of power generation, fuel flexibility will also become a matter of survival.

While having lunch at a downtown café with my friend the biology professor, the subject of animal extinction arose. “When it comes down to it, we really don’t know exactly why most prehistoric species became extinct,” she said. “But we’re pretty sure that one key to long-term survival is being able to quickly adapt to your changing environment.”

“What about crocodiles?” I asked. “They haven’t changed much at all since they appeared on the paleontological scene.”

“Crocodiles found a niche market,” she replied. “They’re littoral apex predators with abundant food sources, benefiting from all the advantages of both land and water habitats. Don’t mess around with crocodiles.”

If you are wondering where I’m going with this anecdote, dear reader, consider this: Most coal-fired power plants were built in an era when coal was cheap, environmental pressures were low, and competition from other generation sources was scant. Over the past decade, however, coal power plants have faced pressures that very few of them were designed to withstand, and in order for a coal power plant to maintain relevance, it will either have to exist in a niche market or adapt and evolve. And one of the most important factors that can determine the survival of a coal-fired power plant is fuel flexibility.

Fuel flexibility can be defined as the ability of a coal-fired power plant to safely, efficiently, and cost-effectively burn a wide range of coals with different properties—or to burn many different potential fuels, such as natural gas, fuel oil, biomass, and unconventional opportunity fuels. Although some coal power plants benefit from a design specification with built-in fuel flexibility, most coal-fired power plants were designed for a relatively narrow range of fuel quality, and—as Figure 1 illustrates—deviating from that range can lead to disaster. With that in mind, the purpose of this article is to demonstrate how improving fuel flexibility, through both capital and operations changes, can evolve your coal-fired power plant and give it a much better chance of survival.

Fuel Flexibility Benefits

The most obvious benefit of fuel flexibility is the ability to burn a variety of different fuels, and thus provide more supply choices when considering both short-term and long-term fuel contracts. However, what is occasionally not understood is the incredible savings that can result from having this ability. As in the case of most economic studies that I perform, it is difficult to receive permission to cite specific company names, but here are some real-world examples where fuel flexibility resulted in significant benefits:

■ An Eastern utility that modified its mills to allow its coal specification to change from a maximum moisture content of 12% to 16% found several new spot market coals were now available for use, resulting in a savings of $4 million in the first year. The cost of the mill modifications: $325,000.

■ A Southwestern utility that frequently blended Powder River Basin (PRB) coal with local coal at a 30:70 ratio modified its mills to allow it to fix a long-standing “hot spot” issue, allowing increased use of PRB coal. Increasing the PRB coal use to 50% resulted in a $23 million savings on the utility’s long-term coal contract. The cost of the modifications: about $1 million.

■ An Illinois utility that reactivated a row of “dead” furnace wall sootblowers above the burner zone discovered it could now accommodate larger quantities of a higher-ash, higher-iron coal into the unit’s fuel diet, resulting in a savings estimated at $500,000 per year. The cost of the repairs: about $120,000.

Beyond individual unit benefits, a 2012 Swedish study of the effects of fuel switching at combustion plants in Europe from 1978 to 2004 found that, not only did units with fuel flexibility have the ability to manage their costs by fuel switching, but also, the price pressure that having a multi-fuel ability placed upon suppliers resulted in limiting price increases even for units that were not fuel flexible.

Risk Reduction. Aside from these more obvious benefits, there are numerous benefits to unit performance, operations, stack emissions, and maintenance practices that can result from increased fuel flexibility.

For example, improving mill maintenance or upgrading one’s mills in order to burn a wider variety of fuels and change operations from achieving maximum continuous rating (MCR) with all mills in service, to having one spare mill at MCR, can result in a significant improvement in a unit’s availability factor. From a study conducted by Black & Veatch on behalf of a 650-MW (net) unit considering mill upgrades, with all other things being equal, the benefit of having a spare mill to accommodate unplanned mill outages and to improve mill maintenance was 7.2 GWh of increased generation opportunity per year (assuming a 65% net capacity factor). At a market rate of $35/MWh, this equated to approximately $250,000 of increased generation revenue per year. Not included in this metric was the improved efficiency of mill maintenance operations and reduced scheduling stress for the maintenance staff.

Future-Proofing Your Plant. Even if your plant exists within a market niche environment, similar to a crocodile, the future is difficult to predict. Almost all power plants are subject to many potential risks that can either curtail or eliminate their ability to maintain their role within their owner’s generating portfolio.

To avoid obsolescence, improvements related to fuel flexibility may include upgrades of existing capital equipment, new and higher-capacity equipment, new generation technology (such as installing a coal additive system or flue gas sorbent injection system), or improved operations via better monitoring and diagnostics hardware and software. And although the U.S. Supreme Court may have set aside the Mercury and Air Toxics Standards (MATS) with its ruling in Michigan v. EPA, very few believe that the progression of environmental regulations on coal power plants is at an end,

Fuel Flexibility with Coal Alone

As mentioned, stack emissions and other environmental regulations are almost certainly not going to be loosened in the future; rather, the trend is clearly the reverse. Increasing fuel flexibility can help one prepare for future emissions regulations while also providing operations benefits.

One example comes from an Illinois coal plant I worked with whose electrostatic precipitator (ESP) was designed for coal with a sulfur content of 1.5% or greater. Knowing that eventually they would need to begin burning low-sulfur PRB coal, plant management undertook a major upgrade to their ESP that included sealing leaks in the ductwork and casing, upgrading the transformer-rectifier sets, and installing an improved rapping and spark control system. Years before the first PRB coal train arrived at the plant’s gates, it had switched to a higher-moisture and higher-ash local coal that ordinarily would have led to derates resulting from both opacity and induced draft fan capacity. However, the upgraded ESP allowed the plant to meet the utility’s load-demand requirements and stay high on the dispatch curve.

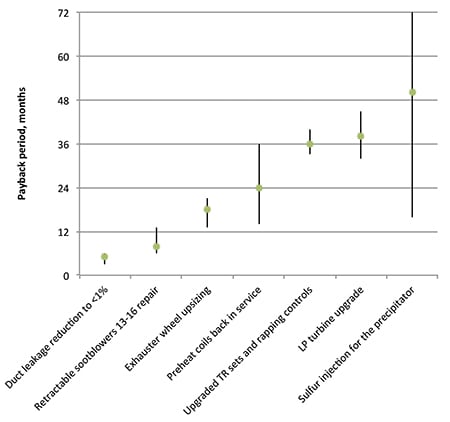

Another utility I worked for had an ancient coal power plant that it had decided to keep alive for the next 20 years via capital improvements, and the plant managers came to me with a question: “Given that our existing coal diet is very limited, and given these capital upgrades that we can make to improve fuel flexibility, which upgrades will give us the best return on our investment?”

To perform this analysis, we obtained operating cost data from the power plant, reviewed its capital expenditure plan, and examined its current short-term and spot coal market situation in the region. Being located directly in the Appalachian region, there were approximately 300 viable sources for truck and train-delivered coal, which we reduced to a “best 60” group for consideration. We then performed a 10-year analysis using the Electric Power Research Institute’s Vista fuel quality impact analysis program to determine the operations risk and total fuel-related cost when burning each of these 60 fuels. We then performed a separate analysis assuming that individual capital improvement projects were undertaken, to see what the minimum, maximum, and mean rate of return was for each plant upgrade.

As shown in Figure 2, some upgrades were obvious, whereas others were high-risk ones. For example, fixing duct leakage in the flue gas path of the power plant provided badly needed margin for an induced draft fan that was struggling, which also reduced the mean gas velocity through the ESP, thus improving particulate emissions performance. On the other end of the scale, adding a sulfur injection system did not address the root cause of many of the core limitations of the power plant, and the effectiveness of the system varied greatly depending upon the sulfur content of the coals that were selected.

The Role of Coal Handling in Fuel Flexibility. One may think of improving the fuel flexibility of a coal power plant via upgrades to boiler and ancillary systems, but one must never forget the important role that is played by the plant’s coal-handling systems.

Coal pile management can be critical for ensuring that a more consistent and better-managed product is delivered to the plant in the first place, thus preventing problems before they begin. For example, as many U.S. generators found, as rail deliveries were falling behind in recent years, plants were being required to dig deeper into their reserve piles and uncover coal that had been significantly aged and weathered. In some cases, this has resulted in 8,800 Btu PRB coals that have tested at 7,800 Btu or less, due to both a loss of volatile matter and an increase in moisture.

Worse still is the situation where a plant “hits bottom” and begins to dredge up coal from the depths of its long-term reserve. One client of mine that was forced to scrape the bottom of the barrel at two of its coal power plants discovered with horror that the PRB coal near the bottom of the pile was testing with an ash content exceeding 50% and a volatile matter content less than 8%! When this coal was mixed with fresher coal from elsewhere in the pile, the result was severe combustion problems and boiler slagging.

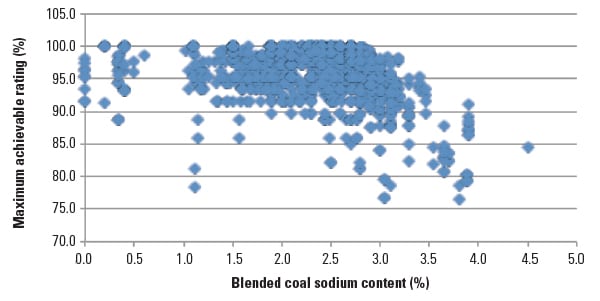

To illustrate how the coal-handling system can influence fuel flexibility, let’s consider the example of a plant I worked at that received coal from two different primary suppliers—one supplying high-sodium coal and the other supplying low-sodium coal—and blended the coals to attempt to meet a specification of about 2% ash sodium content. As shown by Figure 3, when the sodium content was greater than about 2.75%, significant reductions in load were seen due to severe tube fouling in the upper furnace region of the boiler. A study conducted on whether it was more cost-effective to improve fuel flexibility via boiler upgrades or coal-handling system upgrades found that giving the coal yard personnel better equipment to manage sodium swings before the coal was sent to the boiler was the much more cost-effective option.

What Works Best? Generally speaking, it’s been my experience that the following systems are the most likely to yield a benefit both for the bottom line and overall operations efficiency when fuel flexibility is part of a plant’s business and operational strategy:

■ Duct and casing leakage. Everyone has it, and in some cases it’s quite severe. Induced drafts are marginal at many power plants that have not undergone a recent back-end emissions upgrade, such as installing selective catalytic reduction or flue gas desulfurization, and reducing duct and casing leaks can greatly improve operator confidence when burning poorer-quality fuels.

■ Returning “dead” sootblowers to service. A typical scenario involves a coal power plant having a set of sootblowers that were either high-maintenance items or that were located in an inconvenient place to perform maintenance on (such as in the under-arch region of the boiler). As the upper and lower slope of the furnace nose is a common location for slagging and ash deposition to become problematic, bringing sootblowers back into service in this region can result in a return on investment within the first year.

■ Improved monitoring and diagnostics of the boiler. Although significant improvements have been made within the past five to 10 years in terms of upgrades to plant sensors and controls, many coal power plants still short-sheet their operators by not investing in the tools they need to help the plant improve its fuel flexibility. I have witnessed a 400-MW coal unit with but a single oxygen sensor dangling in its flue gas ductwork, a 1,200-MW coal power plant that could only determine its coal burn rate to +/–15% at any given time at any of its individual units, and innumerable instances of operators who were unable to employ reheat steam spray for attemperation even when sorely needed. At one coal power plant I visited, the operators had no trustworthy method of determining whether there was fire in the boiler—so they left an inspection port open and set up two weighted posts with mirrors on top, such that operators could look outside the control room window and see the reflected light from the boiler! While it was an ingenious and simple solution (illustrated by Figure 4), imagine trying to respond to changes in fuel quality for flexible operation with those sorts of limitations.

■ Pulverizer upgrades. This is a topic that could easily take another article to cover, so I’ll be brief. The pulverizer is both affected by many qualities of the fuel (heat content, moisture, and grindability) and affects many qualities of boiler combustion (combustion temperatures, unburned combustibles, NOx and CO production, and slagging). In many cases a simple tuning of roll wheel pressure, ball classification in a ball-tube mill, or air and coal-pipe balancing effort can work wonders for unit performance and fuel flexibility. In other cases, grinding circuit and primary air upgrades may be required.

Dual-Fuel Power Plants

Although the ability to utilize a broad range of coal quality has significant advantages, when those advantages are combined with the ability to utilize a second primary fuel source, then a synergistic effect is seen.

The most common example is the case of a coal power plant that has substantial natural gas cofiring capability. (Editor: For a detailed case study, see the story on this year’s Reinvention Award winner, “Colorado Energy Nations Boiler 5 Upgrade Project,” in the August 2015 issue.) Natural gas cofiring provides many advantages to a coal power plant, including reduced regulated stack emissions, improved operations via lower levels of boiler slagging and fouling, increased margins for coal combustion–related equipment, and decreased production of coal-related waste products (including bottom and fly ash, scrubber waste, pyrites, and mill rejects). Coal equipment life can also be increased by reducing the erosion and corrosion associated with coal combustion, as well as by reducing the loading and duty cycles of the coal-related equipment.

In terms of specific fuel-flexibility advantages, natural gas cofiring provides the following additional benefits:

■ Lower-cost coals can be purchased with less concern for lost capacity. For example, a unit that operates most efficiently using only coals with moisture content of 27% or less (a typical Southern PRB coal) can likely push this specification to include the lower-cost, higher-moisture coals from the Northern PRB. Based on 2016 average projections, the commodity price savings for 8,400 Btu PRB coals is 11.5¢/MMBtu, or $2.5 million per million tons of coal purchased.

■ More aggressive spot market purchasing can be employed. A “finicky” unit that suffers from a variety of exclusively coal-related derates can sometimes find great values on the used equipment market, knowing that if the coal-related equipment isn’t up to the task, natural gas can supplement the heat input and maintain the desired load.

■ Power stations that are unsure about the quality of their coal stockpiles or that suffer from poor or erratic blending practices can put those fears to rest. If, for some reason, too much poorer-quality coal is stocked into the bunkers or silos, then operators can modulate natural gas use to make up the difference.

■ Unexpected outages of parallel equipment (such as coal mills) can be hedged by having natural gas available to make up lost load.

■ Coal inventory levels can be reduced and coal supply delays and shortfalls better managed. Conversely, should natural gas supply restrictions unexpectedly occur, coal use could be increased to maintain the unit generation plan. Last winter one-third of the utilities within the Midcontinent Independent System Operator region had to reduce coal generation and even take units offline due to both rail delays and unexpectedly cold temperatures.

These examples may also apply for other dual-fuel situations, such as coal-oil and coal-biomass cofiring.

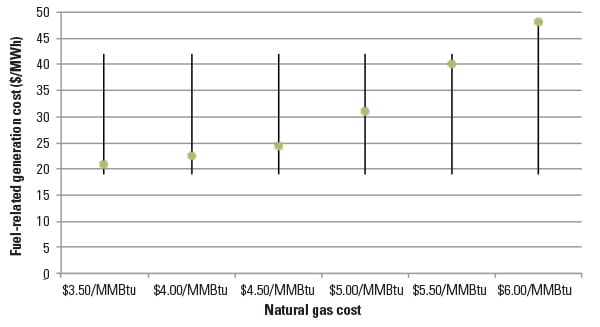

To demonstrate how dual-fuel capability can reduce operations risk, here’s an example that I investigated for a Pennsylvania coal power plant that was able to receive a large number of truck-delivered spot-market coals to supplement a long-term coal contract supplying about half of its fuel purchases.

This plant had limited natural gas cofiring capability, in the form of supplemental burners that could supply up to 12% of the total heat input of the unit at its maximum continuous rating. When reviewing a recent selection of 41 different coal supply bids, we discovered by use of the aforementioned Vista program that the potential range of total fuel-related generation cost was enormous for these fuels, largely due to three factors: some of the fuels were ranked as very high slagging fuels, some possessed a low heating value that led to a unit derate due to insufficient pulverizer and induced draft fan capacity, and some were predicted to exceed the particulate emissions limit of the unit.

Each of these coal cases was evaluated again, assuming that natural gas was available to eliminate derates when one occurred, with a balance between the cost of natural gas consumption versus the cost of the derate itself (as well as the attendant costs of differential maintenance, unit availability, unit stack emissions, dispatch ability, and the like). Figure 5 shows the results of this analysis.

Multi-Fuel Power Plants

When we speak of multi-fuel capability at a coal power plant, we generally are including coal, natural gas, fuel oil, and biomass or some sort of opportunity fuel. In the current regulatory and market climate of most countries there is little advantage to significant investment in biomass cofiring, but in the European community, or nations with a ready supply of biomass, opportunities could exist for leveraging three different fuel markets simultaneously.

Yet another, unorthodox, method of increasing fuel flexibility exists for coal-fired assets within a utility system: capital and operations upgrades that enable those assets to support wind and solar generation being added to the grid.

In a 2013 report published by the National Renewable Energy Laboratory (NREL), the benefits of upgrading coal and gas-fired power plants to improve their operational flexibility (ramp up/down rates, faster startup times, and the ability to operate stably at very low loads) were explored for a test case utilizing the Rocky Mountain Power Pool system. A variety of upgrades to the boiler, pulverizers, combustion air systems, and steam turbine systems were analyzed. The study found that while a cost-benefit analysis may not apply if a single power plant is considered, when a utility fleet is analyzed, the cost-benefit of having improved “fuel flexibility” to support increased wind and solar generation was a total savings of 1.6% per year.

Enabling Fuel Flexibility from Day One

All of the examples provided within this article have concerned themselves with existing coal-fired power plants. Some readers may be in the position, however, of working at a utility or power generator that is considering building a new coal-fired power plant. I am asked to consult on many feasibility studies for new coal-fired units, and I have witnessed a desire for future fuel flexibility being put into practice with much greater attention given to circulating fluidized bed (CFB) boilers over pulverized coal (PC) boilers. In addition to their potentially lower boiler NOx and SO2 emissions, as well as improved performance with high-slagging coals, CFB boilers typically can accommodate a wider range of fuel quality than a PC boiler by nature of their combustion process—not only on a long-term, but also on a real-time basis. A Foster Wheeler internal study cited in the Journal of the Southern African Institute of Mining and Metallurgy concluded in one example that a 600-MW CFB boiler could leverage a fuel arbitrage of 8.7% via its inherent fuel flexibility.

That being said, I also frequently find opportunities where more focus should be placed upon further increasing the fuel flexibility of the proposed power plant. Modern coal power projects are typically being specified with a 40- to 60-year expected life, and I have even encountered one with an anticipated 80-year life. The smartest coal resource scientists on the planet cannot tell us for certain what the price of world market coals will be in 20 years, let alone 40 or 60. Adding to this future uncertainty is the potential for economic disaster, international or civil conflict, geologic resource errors, or sea changes in the geopolitical environmental landscape. Building fuel flexibility into your new coal power plant will almost certainly help save you money and manage your operations and generation risk.

Fuel Flexibility Implementation

In my more than two decades of experience working with personnel from more than 500 generating units around the world, the one resource most utilities lack is the freedom to make investments in their own future. One can blame regulatory uncertainty, unregulated competition, or even (akin to a dinosaur-destroying comet) forces beyond our control. Despite the possible reasons for not considering fuel flexibility in the past, increasing fuel flexibility today has the potential to improve operations and increase profits in both the short and long term, and to potentially keep your generating assets from becoming extinct.

— Una Nowling, PE ([email protected]) is an adjunct professor of mechanical engineering at University of Missouri-Kansas City and the technology lead for fuels at Black & Veatch.