Anyone who has walked barefoot across a parking lot on a summer afternoon knows that blacktop is exceptionally good at soaking up the sun’s warmth. Now, a research team at…

Monthly Issue | October 15, 2008

Anyone who has walked barefoot across a parking lot on a summer afternoon knows that blacktop is exceptionally good at soaking up the sun’s warmth. Now, a research team at…

Owner/Operator: CPS Energy CPS Energy’s J.K. Spruce Power Plant, Unit 1 was recently recognized by the EUCG Fossil Productivity Committee as the best performer in the large coal plant category over the…

Courtesy: Platts Data source: Platts Energy Advantage and POWERmap. All rights reserved.

News items of interest to power industry professionals. EDF and CGNPG create joint venture for Taishan nukes. Électricité de France (EDF) and the China Guangdong Nuclear Power Group (CGNPG) on…

No U.S. federal standards exist to limit worker exposure to hand-arm vibration (HAV), but the National Institute for Occupational Safety and Health suggests that high HAV acceleration levels (5-36 m/s2)…

Owner/Operator: Korea Midland Power Co., Ltd. Top Plant: From tall skyscrapers and flashing neon signs to Buddhist temples and pagodas, South Korea is a mixture of the new and old Asia. Doing…

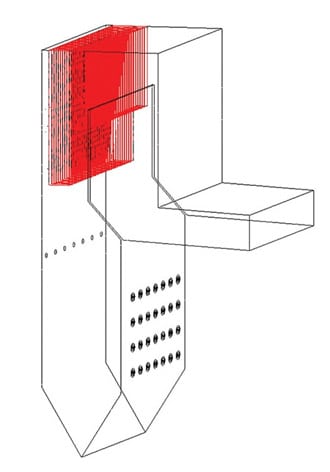

A utility evaluated various methods of obtaining a NOx reduction of at least 30%, as required by upcoming regulations for its boiler, which originally produced 0.54 lb of NOx/million Btu…

How often do you get a clash between two great Lone Star icons? Recently, Willie Nelson, the patron saint of Texas country music, and the Texas & Southwestern Cattle Raisers…

Owner/Operator: Alliant Energy Top Plant: Alliant Energy’s Dubuque Generating Station is a fine example of why small doesn’t mean insignificant in the power generation industry. This winner of the EUCG Best Performer…

As fluid passes through Exact Flow’s new DX-DL dual-rotor turbine flowmeter, the dual rotors become hydraulically coupled due to their counter-rotation. Not only does this allow the rotors to overcome…