The 1940s and 50s are considered the golden age of science fiction literature. After my kids saw the movie, I, Robot, a few years ago, they were surprised to learn…

Monthly Issue | October 15, 2007

The 1940s and 50s are considered the golden age of science fiction literature. After my kids saw the movie, I, Robot, a few years ago, they were surprised to learn…

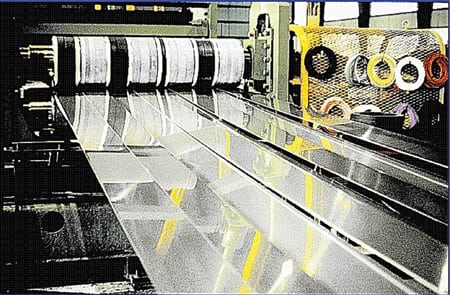

Welding techniques have matured to the point where almost every austenitic, duplex, and full ferritic grade that is made in strip form can be manufactured into a tubular product by…

Siemens ships first blade from U.S. plant This August, the new Siemens wind turbine blade factory in Fort Madison, Iowa, shipped its first blades, bound for the Sweetwater Wind Farm…

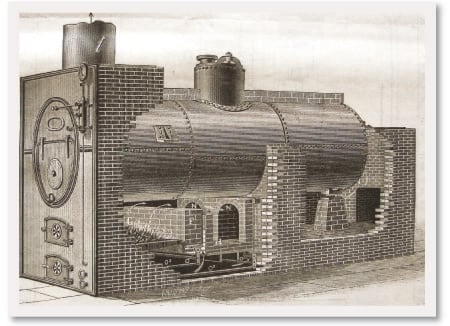

October 1886 In the late 19th century, efficient combustion of solid fuels was achieved more by trial and error than by a fundamental understanding of stoichiometry and staged combustion. Boiler…

COMBINED-CYCLE RELIABILTY Why bypass desuperheaters fail Over the past few years, Thielsch Engineering has been retained several times to inspect, evaluate, and/or repair a through-wall failure of a bypass…

Winston Churchill once said, "Democracy is the worst form of government—except for all the others." The same could be said for competition policy in wholesale power markets. Competition…

Under its Resource Adequacy (RA) program, the California Public Utilities Commission (CPUC) requires load-serving entities—both independently owned utilities and electric service providers—to demonstrate in both monthly and annual filings…

Where there's a will, there's a way. While federal and state legislators and regulators debate the pros and cons of building more coal-fired power plants in the U.S., Japan quietly…

The Clean Air Interstate Rule (CAIR) is pushing utilities in 28 eastern states and the District of Columbia to retrofit many of their coal-fired power plants with selective catalytic reduction…

Tampa Electric Co. (TECO) owns and operates Polk Power Station as part of its regulated generation fleet in Central Florida. The plant (Figure 1) occupies 4,300 acres in Polk County,…