A solar thermal demonstration power plant in Jülich, Germany, that was developed by the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), was formally handed over to its…

Monthly Issue | October 1, 2009

A solar thermal demonstration power plant in Jülich, Germany, that was developed by the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR), was formally handed over to its…

In this column last month I quoted Indian Environmental Minister Jairam Ramesh to represent India’s intention to not agree to any legally binding emissions targets at the Copenhagen Climate Change…

Limestone composition and reactivity are critical factors that determine the performance of limestone-based wet flue gas desulfurization systems. Limestone quality affects sulfur dioxide (SO2) removal, reaction tank sizing, limestone consumption…

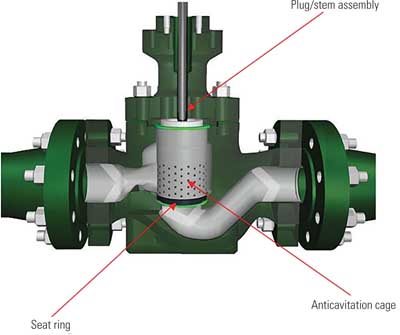

Proper valve sizing and selection saves facilities money by improving plant uptime and decreasing maintenance costs. One way to improve the selection of valves for a particular application is to…

AltaRock Shelves The Geysers EGS Demonstration. AltaRock Energy, a California-based renewable energy company that in 2008 received up to $6 million in DOE funding to demonstrate an engineered geothermal systems…

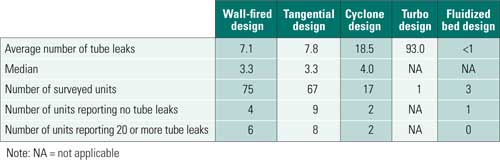

Boiler tube failures continue to be the leading cause of downtime for steam power plants. Is your boiler tube failure reduction program showing improvement when compared to programs at peer…

ESAB Welding & Cutting Products’ newly introduced CaddyTig 2200i AC/DC power source is designed to produce quality gas tungsten arc (TIG) and shielded metal arc (stick) welds in a variety…

When high-temperature boiler feedwater passes through a control valve, the pressure drop can exceed several thousand pounds per square inch, placing extreme stress on the valve body and internal parts.…

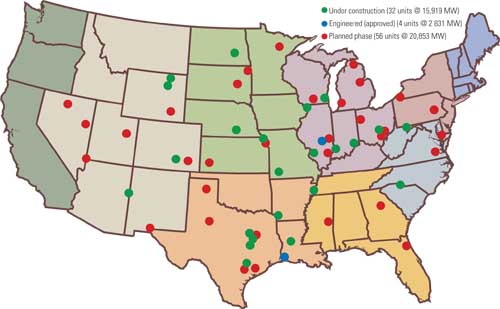

The expected renaissance for U.S. coal-fired generation has been more evolutionary than revolutionary: Less than half of the announced plants will likely progress to construction. However, the percentages for coal-fired…

The design of Nash’s new ECO-FLO builds on the company’s previous liquid ring vacuum pump models. While it offers the same reliability, performance, and operating costs, the ECO-FLO reduces water…