HD Electric Co.’s Phase Rotation Meter (PRM) is used to determine the leading phase of any two phases in a three-phase conductor system. The PRM is a dual-range 0 to 5…

Monthly Issue | August 1, 2010

HD Electric Co.’s Phase Rotation Meter (PRM) is used to determine the leading phase of any two phases in a three-phase conductor system. The PRM is a dual-range 0 to 5…

The cover of the July 5 special History Issue of TIME magazine features Thomas Edison holding a glowing bulb. A series of articles celebrate Edison’s many inventions and closes with…

Luminant used remnants of the ill-fated Twin Oaks and Forest Grove plants (which were mothballed more than 30 years ago) to build the new two-unit 1,600-MW Oak Grove Plant. Though…

The SEL-734P Portable PQ Meter is a new metering solution from Schweitzer Engineering Laboratories (SEL) that addresses the need for complete and portable power quality monitoring. In addition to the…

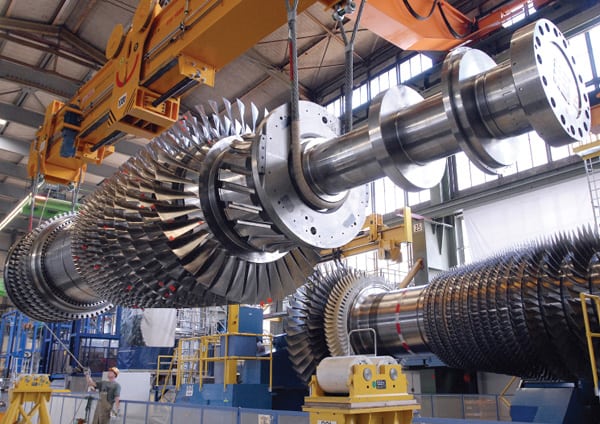

This May, following two years of construction, Siemens Energy put into operation Irsching 5, an 847-MW advanced combined-cycle power plant near Ingolstadt, Germany. The plant’s owner, Gemeinschaftskraftwerke Irsching GmbH—a joint…

With commercial operation of Madison Unit 3, Cleco Power now claims bragging rights for owning the largest 100% petroleum coke–fired circulating fluidized bed power plant in North America. For using…

A new family of Rotating Line Moles (RLM) from NLB gives users more than 40 choices for cleaning pipes and tubes with high-pressure water. Designed for tubes with diameters from…

Nearly a quarter-century after the Chernobyl nuclear power station disaster in Soviet Ukraine, Russia has been making deals with energy-starved nations all over the globe to help them build new…

The refurbishment and restart of all four CANDU reactors at Bruce A may be Ontario’s most significant and complex power generation project since the first phase of the Bruce Nuclear…

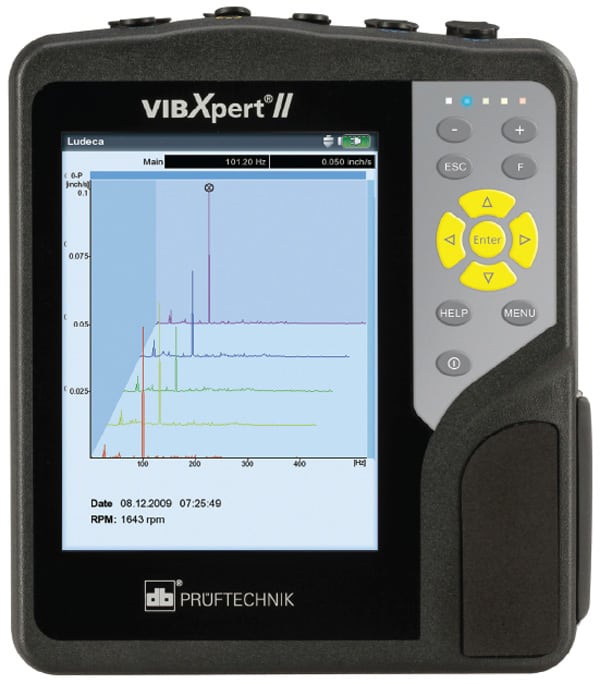

LUDECA has introduced VIBXPERT II, the latest addition to its PRUEFTECHNIK family of portable route-based vibration data collectors. VIBXPERT II is rugged and lightweight and combines the advantages of a…