Himalayan Run-of-River Project Depends on New Component Types

The Himalayan Mountains tower over some of the most rugged terrain and harshest climate conditions on the planet. Melting snows from Mount Everest, K2, and hundreds of other snow-capped peaks carve out more than 6,000 rivers in Nepal, China, Bhutan, India, and Pakistan. The vast majority of the people living along these remote rivers and valleys survive in under-developed living conditions in geographically isolated and difficult-to-access areas. In more ways than one, the rural people of the Himalayas exist off the grid.

The homes and schools in these tiny villages (Figure 1) do not have a consistent source of electricity, although a few have small solar panels that provide enough power for one or two lights. As in most developing countries, basic services—like heat and electricity—are scarce and inconsistent. Small stoves, burning animal dung or scarce wood resources, provide all of the heat and cooking for villagers. Unfortunately, connecting these small communities to existing power grids and centralized power is cost prohibitive.

|

| 1. View from a helicopter of Ringmo, Nepal. Isolated villages, such as Ringmo, offer significant challenges for electricity generation and distribution. Courtesy: US Synthetic |

“Life isn’t easy in a tiny Himalayan community that doesn’t have reliable power,” explains Lynn Tessier, engineering advisor with Advantage Products Inc. “Small rural schools, for example, are limited in their ability to educate students because of the lack of consistent electricity. The schools in these remote villages typically only provide education up to grade seven, and beyond that the children must go to a bigger city, like Katmandu, for additional schooling. And, as is often the case, once the children experience the world at these bigger schools, they don’t return to the village to help improve living conditions or educate the next generation.”

Hydrokinetic Generation System Changes Lives

To combat the scarcity of reliable power, US Synthetic, Advantage Products Inc., New Energy Corp., World Wildlife Fund (WWF), and Himalaya Currents Inc. have teamed up to develop a local, sustainable, clean energy system that can provide Himalayan villages with continuous power. The project relies on an in-stream hydrokinetic power generation system that is submerged in a flume in a nearby river. The 5-kW EnCurrent power generation system (Figure 2) converts kinetic energy in the river’s water current into electrical power. The pollution-free electricity is then transmitted to the village.

|

| 2. A hydrokinetic turbine generator. Using the current of a river, the turbine and direct drive generator can provide continuous power in a free flow environment. Courtesy: US Synthetic |

As a humanitarian project, Advantage Products is donating the EnCurrent power generation system developed by New Energy. New Energy, for its part, is providing project support and flume and weir design. US Synthetic is donating an environmentally friendly, grease-free polycrystalline diamond (PCD) bearing. Funding to transport and install the equipment is being provided by Himalaya Currents. WWF is providing project coordination with local government and communities, permit applications for the project, and travel coordination for the project team. Local community members from the village are also helping out with the project—gathering rock and constructing wire mesh gabions to form the flume and weir in the river and installing the EnCurrent generator.

“The life-changing possibilities of this project are exciting!” explains Jair Gonzalez, general manager for US Synthetic Bearings. “It’s fun to think that our technology might literally keep the lights on in a classroom or help a child learn something new online.”

New Bearing Design Improves Reliability

The project utilizes the flow of the river to keep the hydrokinetic turbine rotors constantly spinning—supplying power 24 hours a day, seven days a week. The generator’s simple design provides clean and continuous power with an extremely small environmental footprint. The industry’s first above-water direct drive generator coupled with the water-lubricated, long-lasting PCD bearings used in the underwater turbine rotor eliminates environmental contaminates like grease or oil.

As snow melts year round in the high Himalayas and flows down into the expansive river system, villagers have access to significant and consistent potential energy. Hydroelectric power generation is more reliable and, in many locations, more easily accessed than other renewable energy sources like wind or solar. The rivers in the Himalayas offer one of the largest, untapped renewable energy sources in the world. The EnCurrent generator is ideally suited to capture potential energy in these remote areas.

Geographically, most remote villages in the region are built in deep mountain valleys that experience limited sunlight. The shadows made by these towering mountains limit the efficiency and effectiveness of solar power (especially when panels are installed within or near the village). Installing solar panels on mountaintops or ridgelines where sunlight is more abundant, presents other problems in construction, system maintenance, and energy transmission.

Like solar power, wind power would present logistical problems—requiring mountaintop or ridgeline construction that would require transmission line construction. In both cases, providing 24-hour power would require a much larger system and an equally large battery storage bank. Batteries also present a significant environmental hazard, are expensive, offer limited life, and present significant transportation challenges in remote areas.

The first EnCurrent system will be installed at the remote mountain village of Ringmo. Ringmo is located on the shores of Lake Phoksundo in the Shey Phoksundo National Park, high in the Dolpa region in Nepal. A suitable location along the river was chosen in April 2013. Ringmo residents were very enthusiastic about the possibility of having electricity for their village (Figure 3).

|

| 3. Ringmo villagers. Residents meet to learn details about the project. Courtesy: US Synthetic |

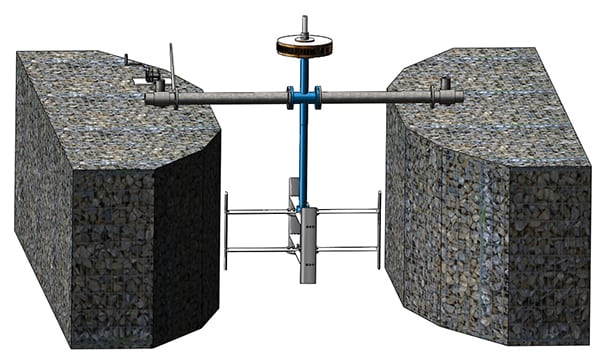

“Villagers were so excited that as soon as they were shown the sketches of the gabion (Figure 4) and weir design (Figure 5), they wanted to go down to the river and begin construction immediately,” says Tessier.

|

| 4. Model image of the gabion with a hydrokinetic turbine installed. The caged rocks form the foundation for the turbine. Courtesy: US Synthetic |

Overcoming Challenging Conditions

“A significant problem with this project is the remoteness of the location. The first location for installation is a three-day walk from the nearest airstrip and a six-day walk from the nearest road. Getting equipment in and out is difficult. And, doing it by helicopter is incredibly expensive,” explains Clayton Bear, president, New Energy Corp. “Because we will have to haul the equipment in by porter or pony caravans, we quickly recognized the need to make our system as simple and lightweight as possible. So, we scrapped the gearbox and focused on a simple above-water direct drive hydrokinetic generator using a submerged water-lubricated PCD bearing for the turbine rotor. This design breaks the system down into small enough components that can be carried by porters and assembled on site with hand tools.”

The biggest challenges facing the hydrokinetic system are underwater abrasion and wear on the turbine’s rotor. As water moves downstream in Himalayan rivers, it picks up more and more debris and sediment—turning the water brown from all of the mud, gravel, and sand churning up from the river bottom. The melting ice from Himalayan glaciers is laden with abrasive sediment. These abrasive particles can quickly destroy standard sealed bearings and wear components on traditional turbine rotors; however, New Energy designed the project’s underwater turbine rotor to work with PCD bearings from US Synthetic.

PCD bearings are ideally suited for operation in harsh process fluid environments where abrasive particles can cause accelerated wear. US Synthetic diamond bearings are designed to be the perfect match for the harshest, most demanding conditions and environments. “In our initial testing, we threw sand and gravel into the PCD bearing to see how it would perform. It seemed to like it—just ground up the particles with no problem. In some ways, it actually worked better,” Bear quipped.

The system was scheduled to ship to Nepal in mid-March 2014, as this issue was being produced. The people of Ringmo plan to install the system in April and May 2014. Once completed, the project will generate 24-hour power, easily handling fluctuating energy loads without losing a lot of energy in the transmission process. PCD bearings will make the generator virtually maintenance free. And, the small, environmentally friendly hydrokinetic system will provide power for needed light and satellite connections to the rest of the world for an isolated, ecologically sensitive area of the planet (Figure 6).

The first installation builds on the concept of localized power. It utilizes clean energy technology and available resources without contaminating the environment in the process. The initial load for the village was estimated to be in the neighborhood of 2 kW, but there is already talk among the villagers of additional uses for the electricity. More units could be installed on the river downstream from the initial system.

There are tens of thousands of locations around the globe, similar to this one in Nepal, that do not have access to continuous, reliable electricity. Thanks to the new technology utilized in this innovative system, that may change in the near future. ■

—Edited by Aaron Larson, a POWER associate editor (@AaronL_Power, @POWERmagazine).