Global Monitor (July/August 2006)

Russia’s new nuclear navy

According to the Russian nuclear agency RIA Novosti, the state-owned nuclear power monopoly Rosenergoatom and the Sevmash shipyard in the Arctic port of Severodvinsk have signed a contract to build the world’s first floating nuclear power plant (Figure 1). A spokesman for Sevmash shipyard says the $336 million reactor will begin construction in 2007 and be commissioned in October 2010.

1. Floating paradox. A digital artist’s conception of the world’s first floating nuclear power plant. Courtesy: Sevmash

Sergei Obozov, head of Rosenergoatom, said that this reactor will provide heating and electricity to Sevmash. But he added that ship-mounted plants like it would be ideal for supplying energy to sparsely populated regions on Siberia’s north coast, on the Kamchatka Peninsula, and in Russia’s far eastern regions, many of which lack a central electricity source. Obozov added that Russian authorities were looking at 11 other possible sites for such reactors and claimed that customers from abroad were already interested in the technology. Russia’s existing 31 reactors at 10 conventional sites account for about 17% of the country’s power generation.

Sergey Kiriyenko, head of the Federal Agency for Nuclear Power (FANP), said that Russia possessed "unique experience . . . on using small and medium-power nuclear reactors." When asked about security, Kiriyenko replied that the reactor won’t be vulnerable because Sevmash —which builds atomic submarines—is sufficiently well guarded.

As for safety, "There will be no floating Chernobyl," Kiriyenko predicted, according to the ITAR-Tass news agency. "It’s no secret that the question has arisen repeatedly: ‘Is such a thing at all possible?’ " Kiriyenko was quoted by his ministry’s press service. "But today the government’s position is such . . . that we are obliged to use our experience. . . . No one else in the world has the experience we’ve accumulated over the years on our atomic fleet of safely operating small-capacity reactors." Unfortunately, not all of that experience has been good.

So far, Sevmash has been less than forthcoming with the project’s specs. But sources say that each ship—measuring 450 feet long and displacing 21,000 tons—will have two small reactors with a total capacity of 70 MW and that the reactors’ thermal energy can be sent up to 180 miles away. The plant’s design life-span is 40 years, with refueling every two to three years. The project is said to have a 12-year payback.

Meanwhile, Sevmash has been busy building two Borey-class nuclear submarines to be equipped with Bulava missiles. The first sub, the Yury Dolgoruky, will be commissioned this year and the second, the Alexander Nevsky, in 2007.

Russia’s old nuclear navy

The Federal Agency for Nuclear Power (FANP) and Russia’s Foundation for Environmental Safety of Power Engineering (FESPE) would do well to at least give their publicists the same script. As FANP was touting Russia’s unique experience with floating nukes (see previous story), FESPE was signing a contract with Fluor Ltd. and British Nuclear Group’s (BNG) Project Services subsidiary to assist with the decommissioning of retired Soviet nuclear subs and with management of their spent fuel and other radioactive waste near the Barents Sea ports of Murmansk and Archangelsk. According to a press release, Fluor Ltd.—the UK operating arm of Fluor Corp. (Irving, Texas)—and London-based BNG are excited to gain a "crucial strategic foothold in . . . an emerging market that is expected to be worth billions of pounds."

Working with Rosatom—the Federal Agency for Atomic Energy—Fluor and BNG will develop a program for cleaning up the former Soviet navy’s nuclear legacy. Until 1990, the Soviet navy routinely dumped radioactive waste in Far Eastern and Arctic waters. There were 13 dumping areas in Arctic seas and 10 off Russian’s east coast, according to Russian environmentalists. Furthermore, the Russian navy simply sank 57 vessels filled with nuclear waste. Sixteen decommissioned reactors were also sent to the deep, including six with unloaded fuel.

Since the collapse of the Soviet Union in 1991, Russia has decommissioned almost 200 nuclear submarines. About 80 still have fuel in their reactors waiting to be dismantled (Figure 2). The press release failed to mention whether the scope of work of the Fluor/BNG contract includes the future of decommissioning the new floating nuclear plants.

2. Take a number. Aerial view of the Zvezdochka shipyard in Severodvinsk, Russia, where a dozen decommissioned nuclear submarines are waiting for their reactors to be defueled and (hopefully) properly interned. Courtesy: Canadian Ministry of Foreign Affairs, Global Partnership Program

First LMS100 fired up by Basin Electric

GE Energy’s first LMS100 simple-cycle gas turbine (see POWER, March 2004, for full details) to enter commercial service did so on July 1 at Basin Electric Power Cooperative’s 95-MW Groton Generation Station in South Dakota (Figure 3).

3. First of its kind. Basin Electric Power Cooperative was the first customer to bring a GE LMS100 gas turbine on-line, at its Groton Generation Station on July 1. Courtesy: GE Energy

At press time, the LMS100 had met the following commissioning requirements: reaching full power after a 12-minute start-up, synchronous condenser operation, and demonstrating guaranteed output, heat rate, and emission levels. The unit also proved capable of achieving full power from a cold metal start within 10 minutes.

Construction of the $69 million plant at the Basin Electric site began in August 2005; the gas turbine-generator set was delivered in November. First fire was achieved in April and full-load operation in May. By early July, the LMS100 had accumulated 138 operating hours of operation and 48 starts.

Basin Electric’s LMS100 unit is fueled by natural gas from the Northern Border Pipeline. The Groton plant was connected to an existing substation operated by the Western Area Power Administration. Electricity will be transmitted to rural electrical systems, which transmit power to cooperatives in northeast South Dakota.

Groton Generation Station will mostly be dispatched as a summer and winter peaker, but it also can be used to stabilize the grid by delivering voltage rather than current. In this operating mode, a clutch between the LMS100’s turbine and generator automatically activates, allowing the turbine to coast down after the generator is brought up to speed. The generator then acts as a large motor or synchronous condenser, explained Dick Shaffer, Basin Electric’s mechanical engineering supervisor and coordinator of the Groton project.

GE has hit the bull’s eye with the LMS100 design. A dispatcher’s dream, the unit can be configured to deliver power in 100-MW blocks (at 44% thermal efficiency, in water-injected simple-cycle mode). At 50% load, the efficiency slips only to 40%. With specs and a design like that, expect to see many more LMS100s springing up around the country in the next few years.

More Jenbacher gensets to Hungary

With many Central and Eastern European cities seeking to modernize their district heating systems, these are salad days for GE Energy’s Jenbacher gas engine business. Jenbacher—based in Jenbach, Austria—has just delivered eight cogeneration units to a large combined heat and power project in a booming industrial city in Hungary (Figure 4).

4. Hungary for power. GE Energy’s Jenbacher gas engine business recently delivered eight natural gas-fueled units to a new combined heat and power plant in the industrial Hungarian city of Székesfehérvár near Budapest. The plant will feed the local public grid and the city’s district heating system. Courtesy: GE Energy

Energott Kft, the project’s general contractor, received eight natural gas-fueled JMS 620 GS-N.LC engine-gensets capable of putting 24.4 MW of electricity on the local grid and generating 22.4 MW of thermal power. The plant, whose commissioning began at the end of June, is owned and operated by Power Plant Developer, Investor Ltd., a Hungarian firm. The engines have been installed at two sites in the city to shorten the distance that heat must travel within the district heating system and to reduce thermal distribution losses.

With about 120 Jenbacher gas engines already operating in Hungary (the smallest rated at 330 kW), GE has established a strong presence in the country—as well as in Romania, Slovakia, and Croatia.

A baseload-size wind farm?

Press releases detailing the latest in a seemingly endless stream of small wind projects don’t really get much attention in POWER’s editorial offices any more. It’s not that we dislike wind power, which has won its rightful place in the grand resource planning scheme of things. But from an editor’s point of view, the next windmill looks just like the last.

Big wind projects do float our boat, however. A good example is the much-discussed 420-MW Cape Wind project off of Cape Cod in Nantucket Sound. America’s first proposed offshore wind project is still probably a year away from completing the latest round of environmental reviews that have tied it up for years and cost its developers over $20 million to date. The project will eventually get the green light, as it should, in spite of the efforts of Senator Edward M. Kennedy (D-MA) and others out to kill it (POWER, June 2006, p. 4).

If big is good, then bigger is better. Toronto-based Trillium Power Energy Corp. recently surprised the industry by proposing to build what it calls Trillium Power Wind 1 some 10 miles out in Lake Ontario, off the coast of Ontario’s Prince Edward County. The project—which still needs environmental approvals and a long-term power-purchase agreement (PPA)—will consist of 142 wind turbines, each with a capacity of 5 MW or 6 MW, depending on what’s available when needed. According to Trillium President and CEO John Kourtoff, if 5-MW turbines are employed, the project’s capacity would be 710 MW; if 6-MW turbines are used, it would be 852 MW. Now you’ve got our undivided attention.

Kourtoff said the project and its site have several attractive characteristics that should expedite approvals: a long history of wind speed measurements, ready access to transmission, and a good technical and financial team. He declined to predict how soon his company might be able to secure a PPA and needed environmental permits but said that, once those were in place, it would take about two years to install the turbines and connect them to the grid. If Kourtoff has his way, Trillium Power Wind 1 could be making power while Cape Wind is still jumping through legislative hoops.

The U.S. could learn something from its neighbor to the north. The Ontario government, unlike ours, has created a positive environment for wind and other renewable energy development. First it committed to put 1,350 MW of renewable capacity on-line by 2007 and 2,700 MW by 2010. Then it followed up with solicitations for the capacity. According to Kourtoff, "[The] regulatory climate for the development of renewable energy in Ontario is the best that it has ever been."

EEI bestows Edison Awards

To recognize their pursuit of excellence in customer service and operations, and their commitment to technological innovation, Edison Electric Institute (EEI) has named Progress Energy and Xcel Energy the 2006 recipients of the prestigious Edison Award. The award, given since 1922, pays tribute to U.S. and foreign shareholder-owned utilities for making outstanding contributions to the electric power industry.

At its annual convention (Figure 5), EEI also named Korea Electric Power Corp. the winner of this year’s international Edison Award. The honor recognizes technological achievements made by the utility in completing two major electricity delivery projects, including building a first-of-its-kind transmission line between an island-bound generating station and mainland Korea.

5. Honoring our heroes. America’s electric utility industry association staged a moving tribute to the line workers who helped restore service following last year’s devastating hurricanes. Forty-five line workers from 30 operating companies, representing the thousands who worked around the clock last year to end outages caused by major weather events, drew a prolonged standing ovation at the opening session of the Edison Electric Institute’s 2006 convention, held in June in Washington, D.C. Courtesy: Edison Electric Institute

5. Honoring our heroes. America’s electric utility industry association staged a moving tribute to the line workers who helped restore service following last year’s devastating hurricanes. Forty-five line workers from 30 operating companies, representing the thousands who worked around the clock last year to end outages caused by major weather events, drew a prolonged standing ovation at the opening session of the Edison Electric Institute’s 2006 convention, held in June in Washington, D.C. Courtesy: Edison Electric Institute

Progress Energy. During 2005, Raleigh-based Progress Energy’s focus on customer satisfaction and operational excellence became a rallying cry for its employees, and an extraordinary year was the result. Over several years, Progress has built a culture of "People, Performance and Excellence," in which employees take responsibility for their own performance and understand how their jobs directly impact the reliability of service to 3 million customers. Last year, Progress became the first utility to receive the J.D. Power and Associates Founder’s Award for excellence in customer service.

The company also operated its nuclear and fossil-fueled plants in a fashion that maximized their availability and minimized production costs. Progress Energy’s nuclear fleet consistently ranks among the best in the industry; two plants—Harris and H.B. Robinson—set production records last year. In 2005, the company’s fossil fleet was equally impressive, with the Roxboro Plant in Person County, N.C., being named the best-performing large plant in the U.S. by the Electric Utility Cost Group. Progress Energy also took the top four spots among small (under 500 MW) fossil plants.

Xcel Energy. Last year, Minneapolis-based Xcel Energy began fully implementing a first-of-its-kind program, Utility Innovations. A partnership of Xcel’s leading technology vendors, the program seeks to more fully leverage IT to drive efficiencies in business operations, cost structure, and energy delivery while increasing customer satisfaction. Xcel Energy scrapped the traditional customer-vendor relationship in favor of having technology providers work together to test and validate new technology and integrate existing technology in untried ways.

Among Xcel Energy’s Utility Innovation initiatives were a first-ever agreement with the National Renewable Energy Laboratory to develop software for evaluating siting options for off-grid and grid-connected commercial rooftop photovoltaic systems in Colorado. Another initiative led to the development of a new software system for analyzing historical and real-time data with an eye toward predicting generation equipment failures and improving plant efficiency.

Xcel Energy also was honored for its environmental achievements in 2005. They included adopting of one of the nation’s largest voluntary emissions reduction programs and committing to become one of the largest providers of wind power in the U.S.

Korea Electric Power Corp. Technological innovation and expertise were the common denominators of Korea Electric Power Corp.’s outstanding achievements last year. As its nation’s sole electric utility, KEPCO has successfully supported Korea’s rapid economic growth by keeping pace with the electricity demand of its 17 million customers. The company finished construction of the 345-kV Younghung transmission line, a project designed to improve the reliability of service to the Seoul metropolitan area. The project required the building of twin marine transmission lines stretching 39 kilometers to deliver power from a Younghung Island–bound generating station to the mainland. (Younghung Thermal Power Plant was one of POWER’s Top Plants of 2005; see p. 78 of last year’s July/August issue for a profile.)

POWERnotes

News items of interest to industry professionals

Supplying PRB units. Babcock & Wilcox Co.

Babcock & Wilcox Beijing Co., B&W’s joint venture company in China, will fabricate most of the pressure parts. B&W’s Diamond Power International Inc. subsidiary will supply the sootblowers. Delivery of materials is scheduled to begin in 2007. The first of the eight units is slated to be on-line in the fall of 2009, with the rest following sequentially through mid-2010.

Russian CHP. In mid-June, Wärtsilä Corp. of Finland was awarded a contract valued at 10 million euros to deliver a 17-MW combined heat and power plant to the city of Eisk in southern Russia by spring of next year. The plant will consist of two Wärtsilä 20V34SG gas engine-driven gensets with heat-recovery systems. It will be the first customized commercially operating pilot power plant optimized by Wärtsilä for Russian municipalities.

Going strong in Europe. In July, Siemens Power Generation (Orlando, Fla.) received an order valued at 450 million euros for an 800-MW turnkey combined-cycle power plant to be sited in Irsching, Germany. The order was placed by Gemeinschaftskraftwerk Irsching GmbH, a joint venture in which E.ON Kraftwerke GmbH of Hanover has a 60% stake. N-ERGIE AG of Nuremberg and Mainova AG of Frankfurt hold the remaining 25% and 15%, respectively.

Siemens PG will be building the new gas-fired plant—to be called Irsching 5—on the site of an existing power station. The company is supplying the gas and steam turbines and their generators, the heat-recovery steam generator (HRSG), and all electrical and control systems. Irsching 5 is scheduled to enter service at the end of 2008.

Also in July, Siemens PG laid the cornerstone of another 800-MW combined-cycle plant it is constructing for E.ON, this one in the northern Italian town of Livorno-Ferraris, between Turin and Milan.

Meanwhile, Siemens is building what will be the largest biomass-fired power plant in the UK. Sited in Lockerbie, Scotland, the plant will be owned and operated by E.ON’s UK affiliate.

GE/Iberinco partnership flourishing. Atlanta-based GE Energy is supplying a Frame 9FB gas turbine-generator for the expansion of Riga II, the largest thermal plant in Latvia. The Riga plant supplies hot water for district heating in the capital city as well as electricity used in Latvia and beyond. The lead contractor on the expansion project is Iberinco, the engineering and construction affiliate of the Madrid-based Spanish utility Iberdrola.

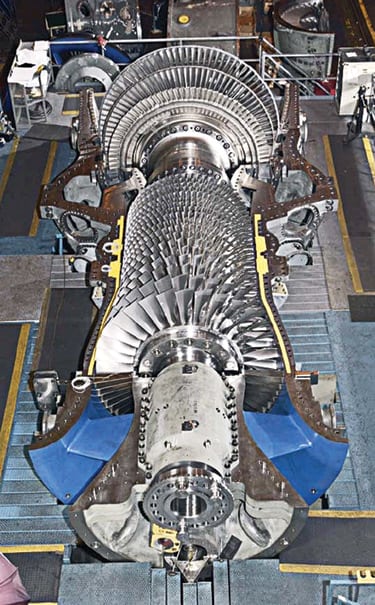

The Frame 9FB (Figure 6) will help power a new combined-cycle block that will increase the plant’s electrical capacity by 420 MW and its thermal output by 270 MW. The turbine and generator will be manufactured at GE’s facilities in Belfort, France, and Schenectady, N.Y., respectively. Both are scheduled to be shipped to Riga in December 2006. The new power block is slated to go on-line in June 2008.

6. 9FB on the half-shell. The rotor of a GE Frame 9FB gas turbine during assembly. GE has received orders for three of the 50-Hz units for power projects in Spain and Latvia. Courtesy: GE Energy

GE Energy and Iberinco previously worked together on Group III of the Arcos de la Frontera combined-cycle plant in Cádiz, Spain, which went commercial in August 2005. The Arcos project marked the commercial debut of GE’s 50-Hz 9FB gas turbine, within a 209FB combined-cycle block. Since then, Iberdrola has chosen the 209FB system for two other new Spanish plants: Escombreras (now under construction in Murcia and expected to enter commercial service this November) and Castellón 4 (north of Valencia).

To be rated at 858 MW, the Castellón plant will use natural gas as its primary fuel and oil as backup. It is expected to achieve a net thermal efficiency of greater than 58%. The scope of GE’s contract includes delivery of two Frame 9FBs, one GE D11 steam turbine, three 330H electrical generators, and two HRSGs. The gas turbines will be equipped with GE’s advanced 2.6+ dry low-NOx combustion systems, keeping emissions of the pollutant under 25 ppm.

$100 million-plus contract.

Atlanta-based Mitsui Babcock (USA) LLC has been awarded a $100 million contract for the steam generator and auxiliary equipment for the Trimble County 2 power project in Kentucky to be built for Louisville Gas and Electric Co. and Kentucky Utilities by Bechtel Power Corp. The 750-MW pulverized coal-fired facility, on the property of the existing Trimble County plant, will operate at supercritical steam conditions, maximizing its efficiency and reducing its CO2 emissions.

Mitsui Babcock’s contract, valued at more than $100 million, will be managed by Bechtel, Trimble 2’s engineering/procurement/construction contractor. Work is about to begin on the project, which is scheduled to be finished in 2010.

Barbara Lefebvre, managing director of power projects at Mitsui Babcock, emphasized that the plant, which will burn a blend of subbituminous and bituminous coals, will be equipped with world-class environmental controls. "For example," she said, "the steam generator will be fitted with our advanced low-NOx burners, and its fuel flexibility also will help lower pollutant emissions."

Geothermal bubbling along. According to the Geothermal Energy Association (GEA), its favorite generation technology is booming in the U.S. Completion of the 45 projects now in various stages of development in western states (including Alaska and Hawaii) will nearly double America’s installed geothermal power capacity, which was 2,828 MW at the end of 2005.

"New state and federal initiatives to promote geothermal energy are paying off," explained Karl Gawell, GEA’s executive director. "State renewable portfolio standards and the federal production tax credit are together driving U.S. geothermal power development."

According to Gawell, the biggest catalyst of the activity was last summer’s passage of the Energy Policy Act. EPAct made new geothermal plants eligible for the full federal production tax credit, which previously was available only to wind projects. It also authorized and directed increased funding for research by the Department of Energy and gave the Bureau of Land Management new legal guidance and secure funding to address its backlog of geothermal leases and permits.

Correction

An article in our April 2006 issue ("Steam turbine upgrading: Low-hanging fruit") has a section on p. 36 describing the Unit 3 steam turbine overhaul completed by KeySpan Corp. at its Northport Power Station on Long Island. KeySpan has asked us to provide some amplifying comments.

KeySpan engineers note that the rationale for the overhaul was degraded performance (peak capacity and heat rate) due to internal seal leakage. Before the overhaul, the unit was load-limited by 15 MW, with the main boiler feed pump at maximum speed. We incorrectly stated that the pump is rated at 15 MW.

The article also stated that "main steam temperature also was limited—by increasing hot reheat temperatures and by the steady falloff in first-stage pressures since the unit’s last overhaul." Clearly, the falloff in first-stage pressure is directly related to seal leakage, but only indirectly to limiting steam temperatures.

Finally, the post-upgrade performance improvement was noted as "465 Btu/kWh (net)—almost twice the predicted 257 Btu/kWh gain." The performance improvement was indeed 465 Btu/kWh (net), but some 317 Btu/kWh of it was attributed to the turbine, even greater than the predicted 257 Btu/kWh gain from that unit.

(Barberton, Ohio) has been chosen to supply eight identical pairs of supercritical boilers and selective catalytic reduction (SCR) systems for Powder River Basin coal-fired units that TXU Corp. proposes building in east Texas. The eight boilers, each with a capacity of 858 MW, will be B&W supercritical Spiral Wound Universal Pressure designs. B&W’s scope includes the SCRs, boiler pressure parts, and auxiliary equipment such as pulverizers, sootblowers, fans and drives, and flues and ducts.