Global Monitor (August 2007)

PG&E mounts tidal power project

Pacific Gas and Electric Co. (PG&E), the city and county of San Francisco, and Golden Gate Energy Co. have agreed to undertake a comprehensive study of harnessing San Francisco Bay tides to generate power.

Specifically, PG&E is committing up to $1.5 million to fund research by "third-party experts." San Francisco is putting up as much as $346,000 for "feasibility studies and stakeholder outreach." Golden Gate Energy, a Florida company that holds a Federal Energy Regulatory Commission license to bring tidal turbines to the bay, says it will cooperate with the project.

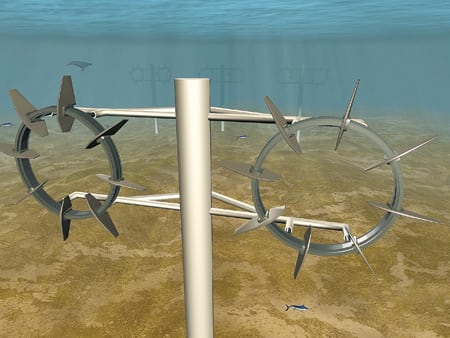

In addition to being renewable and emissions-free, tidal power is reliable and predictable because tides rise and fall with the phases of the moon. PG&E says that siting tidal turbines (Figure 1) would not raise issues of land-use and visual impacts—as do other forms of renewable energy, including wind and solar. A 2006 EPRI study identified San Francisco Bay as one of the world’s most promising sites for tidal power technology.

1. Spin cycle. An artist’s conception shows one possible way to capture the dependable power of tides in the Golden Gate area. Courtesy: PG&E

"Exploring the potential for harnessing the tide in the Golden Gate to deliver new supplies of clean power to our customers is one of the most exciting renewable energy possibilities being explored anywhere in the world today," said outgoing PG&E CEO Tom King. San Francisco Mayor Gavin Newsome said, "We all agree that it is imperative that we develop new alternative energy sources like tidal energy."

Key drivers of the research program are California’s aggressive renewable portfolio standard (RPS) program and the state government’s push to reduce greenhouse gas emissions. PG&E says it is now adding more than 300 MW annually in renewable resources. This year, the San Francisco–based company has already signed contracts to buy 274 MW of wind, solar, geothermal, and other qualified renewables under the state’s RPS program.

PG&E says the initial phases of the tidal current study will begin this summer and take about a year to complete. "If findings in the initial rounds of research affirm the feasibility and promise of tidal power," the utility said, "future plans could ultimately lead to the development of a full-scale commercial project."

The San Francisco utility says it is now getting some 13% of its energy from renewables that qualify under the California RPS program: solar, wind, biomass, geothermal, and small hydro. Counting large hydro and nuclear, more than half of the electricity that PG&E delivers to its customers comes from generation that emits no or little carbon dioxide. PG&E is also looking at the possibility of harvesting electric power from Pacific Ocean waves off the coasts of Mendocino and Humboldt Counties.

GE F-class turbine breaks record

General Electric Co. reports that its installed fleet of F-technology gas turbines has now accumulated more than 20 million hours of commercial operation in power plants around the world.

What’s more, says GE Energy, the company is expecting to ship its 1,000th F-class machine this summer. Steve Bolze, GE Energy’s power generation chief, said the F-class turbine (Figure 2) "has become an industry benchmark for efficient and reliable electricity production" over the past 20 years. A company press release adds that the machines "were the first gas turbines in their class to reach 40% turndown while maintaining single-digit NOx and CO emissions."

2. F, for first. General Electric’s long-lived, high-performing Frame 7 gas turbine has repeatedly raised the bar for efficiency since its introduction in 1987. Courtesy: General Electric Co.

GE introduced F technology in 1987, just as use of natural gas to generate electricity was beginning a worldwide boom. The first unit was shipped in 1988 and entered commercial service in 1990 at Dominion Virginia Power’s Chesterfield site in Virginia. In 1989, Tokyo Electric Power picked F-class turbines for a 2,800-MW expansion of its Yokohama power station.

In 1994, notes GE, a 7FA unit at Korea Electric Power Corp. became "the first gas turbine in the world to reach 55% thermal efficiency in commercial combined-cycle operation." In late 1995 and early 1996, a Frame 7FA at Sithe Energies’ Independence plant in Oswego, N.Y., recorded 100% availability and reliability over 108 days of continuous operation.

Moving into the 21st century, in 2002, GE Frame 7s surpassed 5 million fired hours in worldwide service. In 2004 and 2005, China’s Gas Turbine Power Plants Construction Project picked GE to supply 20 F-class machines for the first two phases of its plan to meet growing electricity demand while limiting pollution. In late 2006 and 2007, Saudi Arabia said it would buy 35 F-technology gas turbines for power projects in the oil-rich kingdom.

According to data from GE’s Operational Reliability Analysis Program, the 7F is the most reliable F-class turbine and the first to achieve 99.1% reliability. According to GE, the newest member of the F family, the Frame 9FB, "has achieved combined-cycle efficiency exceeding 58%." Mated with GE’s high-efficiency advanced technology (HEAT) steam turbine in a combined-cycle operation configuration, the 9FB "can produce more than 412 MW, a significant increase over the 9FA’s combined-cycle output of approximately 390 MW."

Iowa welcomes ethanol-fed hog

That familiar, ear-splitting, pulsating rumble and roar you hear is the power of corn.

Paul Teutul Sr. and his sons, Paul Jr. and Mikey—the stars of the cable TV hit "American Chopper" and the proprietors of Orange County Choppers—have converted a stock Harley-Davidson motorcycle to run on E85 fuel (85% corn-based ethanol and 15% gasoline). The "corn chopper" is part of an Iowa Farm Bureau (IFB) program called "Join the Ride Iowa" that seeks to boost development of renewable energy from the U.S. corn belt.

Craig Lang, president of the IFB, an independent farmers’ organization, said his group got involved in the project "because Iowa is the epicenter of renewable energy activity through our leadership in ethanol, soy biodiesel, wind, and livestock production." More than any other state, Iowa understands agriculture and we knew if anyone could showcase that, it would be the Teutuls."

The striking motorcycle (Figure 3) has some unusual elements designed to feature renewable energy:

- Wheel spinners that "run to the scale of a genuine wind turbine," reflecting the state’s burgeoning wind industry.

- Front fenders with sculpted ears of corn, and rear fenders embedded with soybeans. Iowa is America’s leading producer of corn, beans, ethanol, and biodiesel.

- Custom leather seats that include images of livestock, another important part of the state’s agricultural economy and the consumers of the by-products of ethanol production.

3. Corn chopper. Orange County Choppers impresario Paul Teutul Sr. revs up the motorcycle he built for the Iowa Farm Bureau to promote biofuels. In the background, on the left, are sons Paul Jr. and Mikey. Courtesy: Iowa Farm Bureau

Paul Teutul Jr. said, "We had no idea Iowa had so many cutting-edge renewable energy efforts under way until we came to the state for inspiration" during the motorcycle’s design. He added that Iowans "are literally using every component of agriculture" to change energy use in the U.S. The IFB news release did not quote Paul Sr., probably because most of his remarks would have been unprintable.

Iowans and others will have a chance to win the corn chopper this summer by buying $10 raffle tickets. Gross proceeds from the raffle will go to the American Lung Association of Iowa to support its consumer education program promoting E85.

Orange County Choppers isn’t just another small California custom motorcycle shop; it’s a big business. The company has five dealers in New York, Michigan, Texas, Colorado, and Florida, and is actively recruiting more.

NYPA upgrades pumped-storage plant

The New York Power Authority (NYPA) has upgraded one of the four units at its 1,000-MW Blenheim-Gilboa pumped-storage plant to meet summer peak loads. The effort is part of a multiyear plant life-extension project.

The newly refurbished generating unit (Figure 4) resumed operation in late May after having been out of service since September 2006. A second unit will be shut down for upgrading this September and is slated to return to service in June 2008. The plan is to refurbish all four units by 2010.

4. Heavy lifting. This 190,000-pound turbine was installed as part of the staged refurbishment of the New York Power Authority’s 1,000-MW Blenheim-Gilboa pumped storage project in the Catskill Mountains. Courtesy: NYPA

Blenheim-Gilboa began operations in 1973. Its turbines generate power by drawing water from two high reservoirs when needed, typically during hot summer weekdays. When demand ebbs, at night and on weekends, the turbines pump water back up to the reservoirs. "A key goal of this first stage of the project was to return the first refurbished generating unit to service before this summer, and we achieved it," said Allen Schriver, NYPA regional manager for central New York.

Each of the two reservoirs can hold about five billion gallons of water. The top reservoir is atop Brown Mountain, and the lower one is 1,200 feet below. According to NYPA, the plant can start generating power within two minutes of a call for it.

According to a NYPA press release, the $135 million upgrade of the first unit "will allow Blenheim-Gilboa to produce more power from the same amount of water while extending the facility’s record for reliable service for decades ahead."

Last December, NYPA inked a 15-year deal to upgrade its Niagara Power Project near Niagara Falls. Earlier, the state-owned public power agency started a life-extension project at its St. Lawrence-Franklin D. Roosevelt project in Massena, N.Y., on the Canadian border. That project, said NYPA, should be completed by 2013.

Created when Franklin D. Roosevelt was governor of New York, Manhattan-based NYPA is the largest state-owned electric utility, with 18 power plants and more than 1,400 miles of transmission lines. Hydro plants account for about 75% of NYPA’s generating capacity. NYPA was the model for the federally owned Tennessee Valley Authority, which Roosevelt created when he was president.

Bush blesses Browns Ferry 1 restart

President George W. Bush was in Decatur, Ala., this spring to celebrate the restart of Tennessee Valley Authority’s (TVA’s) Browns Ferry 1 nuclear power plant. It had been mothballed for 22 years.

Bush (Figure 5) toured the refurbished (at a cost of $1.8 billion) 1,200-MW GE boiling water reactor, which TVA closed in 1985 along with two other Browns Ferry units. The systemwide nuclear shutdown was driven in part by investigations by House Energy and Commerce Committee Chairman John Dingell (D-Mich.). TVA delayed bringing Browns Ferry 1 back on-line sooner because, at 34, it is the oldest nuke on its system. Other, younger nuclear units at Browns Ferry and Sequoyah had been restarted earlier.

5. Bush at Browns Ferry. President George W. Bush, right, in the control room of TVA’s Browns Ferry 1 nuclear unit. It reentered service this spring better than new after spending 25 years in mothballs and getting a $1.8-billion, five-year refurbishment. Courtesy: U.S. Department of Energy

Soon after Browns Ferry 1 went on-line in 1973, TVA broke ground on the 1,167-MW Watts Bar 1 pressurized water reactor, which entered commercial operation in 1996. Watts Bar was the last new nuclear plant to be commissioned in the U.S. TVA is now considering resuming construction on Watts Bar 2.

The Browns Ferry 1 restart program began in 2002. Over the past five years, the original unit—state-of-the-art in 1973 but now considered primitive—was essentially rebuilt as a modern unit that barely resembles its predecessor.

Bush used his visit to Alabama to push for reprocessing spent nuclear fuel, an issue largely tangential to the plant’s restart. "We ought to do something about reprocessing," he said. "We ought to bring new technologies to bear to help us all deal with spent fuel." The president then boosted his "global nuclear energy partnership" or GNEP program, which so far has elicited languorous, bipartisan yawns in Congress.

The Nuclear Energy Institute (NEI), as the lobbying group for the nuclear power business, predictably ate up Bush’s appearance at Browns Ferry. Skip Bowman, NEI CEO, said Bush’s visit to Alabama "is a fitting tribute to the thousands of men and women whose hard word and dedication over the past five years made refurbishment of Browns Ferry 1 a reality."

Bush also took the opportunity to push his political agenda on energy and slam the energy bill advancing in the Senate, which now is controlled by Democrats. "The current plan being debated in the Senate," he said, "falls far short of the ambitious goal I laid out." He described his goal as "realistic" and called on Congress to "get [my bill] to my desk so we can all say we’ve done a good job of representing the people."

But the Bush bill is controversial, including a limited version that recently passed the Senate. Both Republicans and Democrats have criticized it as nibbling at the edges of energy policy.

Shearon Harris looks to live on

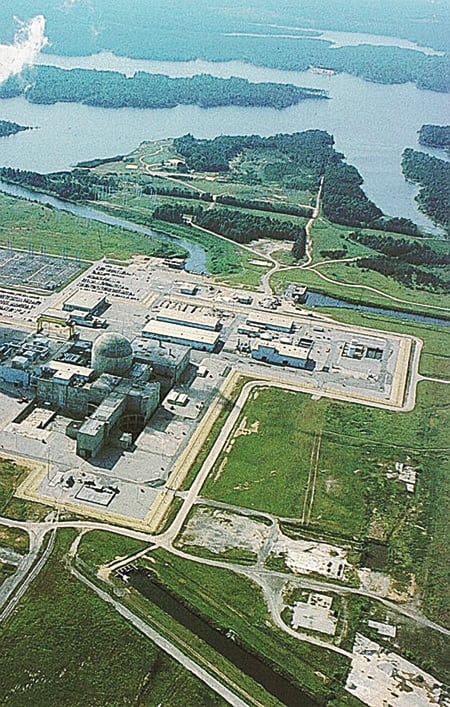

The U.S. Nuclear Regulatory Commission (NRC) last month rejected a petition by locals opposed to extending the operating license of Progress Energy’s 900-MW Shearon Harris nuclear power plant (Figure 6) for another 20 years.

6. Opponents of Shearon Harris defeated. The NRC has rejected locals’ claims that extending the license of Progress Energy’s 900-MW Shearon Harris pressurized-water reactor for 20 years is not in the public interest. Courtesy: Progress Energy

The single-unit pressurized-water plant in New Hill, N.C., began operating in 1987 under a 20-year license. The Progress Energy subsidiary Carolina Power & Light has applied for a 20-year extension of the license, in line with NRC rules.

Last April, the NRC set a schedule for reviewing the license renewal application that included public hearings in July run by the independent Atomic Safety and Licensing Board (ASLB). According to press accounts, those hearings generated little opposition to the relicensing. If opponents of the license extension fail to persuade the ASLB, they can appeal its decision in federal court.

This June, the NRC dismissed claims by critics dating back to 1989 that the plant is particularly vulnerable to fire. They wanted Progress, which is based in Raleigh, N.C., to be fined $130,000 or have its nuclear operating license revoked. The NRC disagreed, and the opponents appealed to the ASLB. At press time, the ASLB had not issued an opinion.

The NRC has yet to rule on the license renewal, but the betting among nuclear power insiders is that Progress will get it because extensions have become almost automatic at the NRC.

On a related issue, workers at Shearon Harris and two other Progress Energy nuclear plants—Brunswick, near Southport, N.C., and Robinson, near Hartsville, S.C.—resoundingly rejected representation by the International Brotherhood of Electrical Workers (IBEW). According to press accounts, nonmanagement employees at the three plants voted 499-157 against joining the union.

The IBEW, which says it represents nonmanagement workers at about 75% of the nation’s nuclear plants, mounted a major organizing drive, starting at the Brunswick plant, in 2006. The campaign spread to Harris and Robinson this year. The union petitioned the National Labor Relations Board for a vote at the end of May, apparently confident that it would win.

Unions aren’t particularly popular in the Carolinas. The Raleigh News and Observer noted at the end of June that "Progress Energy hasn’t had a unionized employee on its payroll in the Carolinas in nearly three decades."

In a press release, Bill Johnson, chief operating officer of Progress Energy, said, "I am more confident than ever in the people and the future of Progress Energy." According to the Raleigh newspaper, North Carolina and South Carolina have the lowest rates (3.3%) of union membership in the country. Under federal law, the IBEW cannot begin another organizing drive at the three plants for one year.

Nevada bets on solar thermal

A parabolic solar thermal power plant in the Nevada desert began generating electricity for the state’s grid this June. The 64-MW project, say its German and Spanish developers, "is the first large solar thermal plant to be built in 15 years."

The developers’ claim is technically accurate. But the project, as the developers acknowledge, is smaller than the Luz parabolic concentrator projects of the 1980s that sold power to Southern California Edison under contracts designed to implement the 1978 Public Utilities Regulatory Policies Act.

"Nevada Solar One" (Figure 7) covers 250 acres of the Nevada desert with arrays of solar parabolic concentrating troughs (Figure 7) that focus the heat energy of the sun on power-producing turbines. The plant’s output will be sold to Nevada Power and Sierra Pacific Power under long-term power-purchase agreements.

7. Dishing up the sun. These parabolic concentrators in the Nevada desert have begun producing 64 MW of sun power for Sierra Pacific Resources’ two Nevada utilities. They are similar to those used by earlier Luz solar thermal generation projects in California. Courtesy: Schott North America

Udo Ungeheuer, head of the solar power promoter Schott AG—a German glass maker that provided the concentrator technology—said at the end of June in Dusseldorf that the EU "should work towards establishing the necessary basic parameters so Europe can one day be supplied with power from solar thermal power plants based along the Mediterranean."

According to Ungeheuer, the parabolic trough technology "has already proven itself, and the costs of generating electricity will soon be competitive." Acciona Solar Power Inc., a subsidiary of Spain’s Acciona group, built the plant and will operate it.

Similar to the Luz projects in California, the Nevada project has trough-shaped mirrors that concentrate sunlight onto absorber tubes along the focal length of the mirrors. The working fluid in the tubes is first heated to nearly 750F and then is pumped to a heat exchanger plant that transfers the energy to water used to make steam. The steam turns a steam turbine-generator. On cloudy days, a gas-fired generator is used to maintain the plant’s output.

Climate models questioned

Current global climate circulation models, used to predict climate change, don’t accurately reflect the roles of the Northern and Southern Hemispheres, according to a recent research article in Science magazine, the journal of the American Association for the Advancement of Science.

Conventional wisdom, according to an article in the June 22 edition of the magazine, holds that the Northern Hemisphere and the tropics are a strong sink and source, respectively, of CO2.

Not necessarily so, says a study by a group of climate scientists led by Britton Stephens of the National Center for Atmospheric Research in Boulder, Colo. Their report in Science finds that measurements of the vertical distribution of CO2 in the atmosphere (Figure 8) are "inconsistent with atmospheric models that estimate a large transfer of terrestrial carbon from tropical to northern latitudes." In other words, the tropics are sequestering more carbon than the models predict.

8. Layering the atmosphere. New research, using vertical distributions of carbon dioxide in the atmosphere measured by aircraft at 12 global sites, suggests that global circulation models do not do a good job of assessing the "sources and sinks" relationship of the Northern and Southern Hemispheres. Courtesy: Britton Stephens

The implication, that models of very complex nonlinear systems have limitations, is a point that climate change skeptics have been raising for more than a decade. The article states, "Our ability to diagnose the fate of anthropogenic carbon emissions depends critically on interpreting spatial and temporal gradients of CO2 concentrations."

An earlier questioning of the climate models’ accuracy on sources and sinks came in a May 17 article in Science’s online service; it suggested that the uptake of CO2 by the Southern Ocean has slowed more than the models predict. Lead author Dr. Corrine Le Quéré of the Max Planck Institute in Germany noted that carbon sinks "are highly variable and sensitive to climate, yet they are poorly constrained by observations." In other words, the models make assumptions that aren’t necessary based on empirical data.

What does all this mean? Nothing definitive, apparently, but just a cautionary tale about the limitations of computer modeling when it comes to very complex, nonlinear systems.

POWER digest

News items of interest to power industry professionals.

On-line monitoring of catalyst life. The U.S. Department of Energy (DOE) has announced the availability of a tool for in-situ testing of the activity level of catalysts used by selective catalytic reduction (SCR) systems to control plants’ NOx emissions. In a press release, the DOE claimed that the Knoxcheck Online system will help "plant operators to more cost-effectively comply with NOx emission regulations, including the new Clean Air Interstate Rule."

Fossil Energy Research Corp. (www.ferco.com) developed the technology, which can monitor catalyst activity in an SCR system without having to shut it down to obtain samples from different layers—the traditional approach. The Knoxcheck system was tested at full scale on one unit of Southern Company’s Gorgas plant, and the results were "similar to those obtained from traditional laboratory testing of catalyst activity," according to the DOE.

The DOE added that linking the results from Knoxcheck to data from EPRI’s CatReact catalyst management software "helped Southern Company make proactive decisions about the operation of the SCR system and [evaluate the] overall NOx compliance on the unit."

Keeping track of remaining catalyst life is crucial to the economic operation of SCR systems because catalysts are a big part of such systems’ overall cost. The ability of a catalyst to convert NOx to benign chemicals degrades over time because its surface is prone to pluggage by flyash. In SCR systems with multiple layers of catalyst, each layer can degrade at a different rate.

Alstom and E.ON plan carbon capture demo. Alstom and E.ON are launching a 5-MW demonstration of CO2 capture at a power plant in southern Sweden. The demonstration, at the Karlshamm plant, will use Alstom’s chilled-ammonia technology and is expected to begin in 2008.

According to an Alstom press release, research suggests that the technology can remove up to 90% of the carbon dioxide in flue gas. The company also says that using chilled ammonia for this purpose consumes far less energy than competitive technologies. Alstom says its studies predict a 10% energy loss, vs. a nearly 30% loss for other post-combustion CO2 capture techniques.

The Alstom-E.ON deal is reminiscent of an agreement between Alstom and American Electric Power for a test at a West Virginia coal-fired power plant that also has a 2008 start date. If the AEP test works, the Ohio-based utility holding company will build a full-scale plant in Oklahoma in 2011. Wisconsin Electric Power is also working with Alstom on a carbon capture demonstration at the former’s Pleasant Prairie plant.

Siemens completes offshore UK wind project. Siemens Power Generation says it has finished installing 25 3.6-MW wind turbines at the Burbo Offshore wind farm in Liverpool Bay. The project will be operated by SeaScape Energy Ltd., and its power will be sold into the UK grid. SeaScape is owned by the Danish utility DONG Energy A/S.

Siemens said it got the job done in one and one-half months, "well ahead of schedule." The project is expected to enter commercial service by the end of the year. For its onshore operations in support of the project, Siemens leased 45,000 square meters in North Wales. The German power giant says it assembled the 65-meter-high steel turbine towers upright and then tested all of the turbines’ internal components and the plant’s electrical systems before loading the towers onto a specially designed vessel that took them 7.5 miles offshore.

On each trip, the vessel carried the housings, hubs, and blades of three turbines. According to Siemens, the average time it took to erect one turbine, weighing almost 500 tons, was less than half a day.

The Burbo wind farm was the first offshore wind project for Siemens and the first in a series of projects that have ordered the company’s 3.6-MW turbine. The next delivery, of smaller units, will be to the Swedish utility Vattenfall. It hopes to have 48 Siemens 2.3-MW turbines with a total capacity of 110 MW generating power offshore of Malmö by the end of this year.