Don’t Let Leachate Derail Your CCR Landfill Plans

Developing a compliance approach for a new regulation sometimes means overlooking unintended consequences of the chosen compliance method.

Preparing for compliance with the new U.S. Environmental Protection Agency (EPA) regulations on coal combustion residuals (CCR Rule), published in the Federal Register on April 17, 2015, is causing many power producers to make significant changes to their operations. These changes can include eliminating the use of surface impoundments, changing their coal-fired process from “wet” to “dry,” and developing lined disposal landfills to contain the CCR their plants produce.

Although some U.S. states have required landfilling of CCR for some time, it is a new requirement for power producers in many parts of the country. These operators need to be sure that their plans do not get derailed by failing to account for liabilities stemming from unexpected causes. One of these is “leachate”—water from stormwater precipitation that comes in contact with the CCR in the landfill. Water contacting CCR will “pick up” contaminants and must be contained and disposed as wastewater—not stormwater.

The CCR Rule does not specifically define the water that comes in contact with CCR materials as being “leachate;” however, the term is defined in other parts of Subtitle D (40 CFR Part 258) and it is used extensively throughout the CCR Rule. The EPA and many state-equivalent agencies define leachate from municipal solid waste (MSW) landfills as water that has come into contact with the MSW—including contact stormwater and infiltrated water. These agencies also require management of MSW leachate separate from noncontact stormwater, in lined ponds and vessels.

It is likely that these agencies will require the management of leachate from CCR landfills to follow similar guidelines. This is because leachate coming from a CCR landfill has the potential to contaminate surface water and groundwater, including water that collects in wells for human consumption. For these reasons, management of leachate associated with any waste has long been in the cross-hairs of environmental regulators, environmental activist groups, elected leaders, and the general public.

Specifically, the CCR Rule requires that the liner systems for new landfills, or lateral expansions to existing landfills, include a leachate collection and removal system (LCRS, Figure 1) and limits the maximum allowable head of leachate buildup atop of the liner system to less than 30 centimeters (12 inches). This head restriction requires the regular and continuous removal of leachate from the landfill liner system. The CCR Rule, however, provides no further requirements for the management of leachate after it is removed from the landfill.

|

| 1. Installing liner geosynthetics. Courtesy: Golder Associates Inc. |

For CCR landfills, environmental regulators’ biggest concern about leachate from CCR is heavy metals, including arsenic, mercury, and cadmium. This means that utilities will do well to look to methods that have helped municipal landfill operators manage leachate in a way that meets regulations and reduces the quantity generated. Methods for managing CCR landfills, developed in states where these have long been required, can also be helpful.

Next are some of the principles learned in designing, building, and operating leachate management systems for both MSW and CCR landfills.

Less Leachate Produced = Less Leachate to Manage

Leachate management and disposal can be the single largest operational expense at a landfill. One of the key principles of leachate management is to keep the “problem” (and cost) as small as possible. Producing less leachate means lower costs, fewer liabilities, and fewer things to go wrong.

One principle of good landfill management that reduces leachate is to develop the landfill in “cells”—subsections of the landfill, each underlain by a regulatory-required liner system, which often includes an impervious barrier such as a high-density polyethylene (HDPE) layer. Above that barrier layer is the LCRS, often a high-flow drainage layer, which intercepts any infiltration that percolates through the waste, or CCR in this instance.

Each cell has an engineered low point, or “sump,” into which leachate accumulates. A pump, placed into the sump through a riser pipe, removes the leachate for treatment or disposal (Figures 2 to 4). Certainly, there are other configurations for leachate removal, but this is the most common approach.

|

| 2. Leachate collection line being installed in a cell. Courtesy: Golder Associates Inc. |

|

| 3. Sump pump and risers. Courtesy: Golder Associates Inc. |

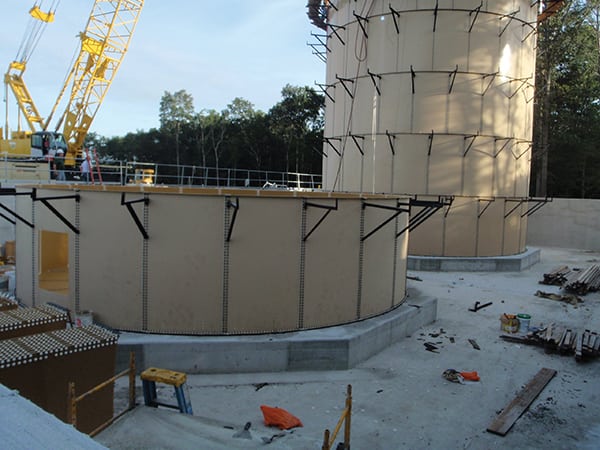

|

| 4. Leachate tanks under construction. Courtesy: Golder Associates Inc. |

Having the landfill developed in cells means that only a limited part of the total area is exposed to precipitation at any one time. This has the effect of reducing the amount of potential leachate that must be treated/disposed.

The size of the cell depends partly on the rate of CCR generation and disposal. Generally, the cells would be sized such that each will have a three- to five-year lifespan. After a cell is full, it is capped with a final closure cap, often including an impervious geomembrane, to minimize or prevent inflow of stormwater that would contribute to ongoing leachate generation (see opening photo).

It’s possible to further reduce the volume of leachate to be treated by dividing each cell into sub-cells, during initial filling when the entire cell “floor” is exposed to rainfall, instantaneously becoming leachate as soon as filling commences.

To see how this helps, visualize a newly started cell, several acres in size, which has only a thin layer of CCR over part of the cell “floor.” Rain or snow falling on the cell would come into contact with the CCR quickly and produce a large volume of liquid that must be considered leachate. The large volume of liquid also carries the risk of overwhelming the pump used to remove leachate for treatment. This could also put the landfill owner in breach of the CCR Rule’s restriction on maximum allowable head atop the liner.

By building berms within the cell to create several subcells, the infilling with CCR can be limited to only a subcell within the larger cell. This means that any precipitation falling on other subcells that do not yet contain CCR can be considered stormwater rather than leachate and can be sent to the facility’s stormwater management system. This greatly reduces the handling costs involved.

In addition, smaller subcells reach a greater depth of CCR more quickly as they are being filled, so that precipitation falling on them has a chance to percolate more slowly through the ash, and the pump is less likely to be overwhelmed by a heavy storm.

There are several other operational considerations that may also be used to reduce the generation of leachate, including the use of temporary soil covers and temporary geosynthetic covers.

Lessons from Municipal Landfill Operations

In developing their landfill operation, many coal-fired power generators will look to engineering firms, contractors, and equipment suppliers who have experience with designing and operating MSW landfills. That can be very helpful, as many of the issues that MSW operators face are similar to those faced by CCR landfills.

But there are differences. One significant difference is the type of constituents detected in the leachate. MSW leachate contains a high degree of dissolved solids from a wide variety of sources, depending on the composition of the waste material. Leachate from CCR landfills has a high proportion of fines—dust-sized particles, particularly from fly ash. These particles have the potential to clog LCRS and sump pumps and can cause abrasion that increases maintenance costs as well as limiting service life of the pump.

For this reason, filtration systems are important in CCR landfills, to keep the fines from entering the LCRS and then the pump. Some geosynthetic manufacturers advertise specialty geocomposite drainage layers recently developed for LCRS use in CCR landfills, but those have not been widely applied in the industry. The author is aware of several geosynthetics manufacturers performing bench-scale testing of these products with CCRs.

Design Leachate Management into Landfill Designs

Because of the potential for leachate to put a landfill operation into regulatory violation, it is important for power producers to plan leachate management steps into their designs, from the start.

This helps to reduce the chances of stop-work orders, financial sanctions, and other negative consequences from disrupting operations. It also helps reduce the chance that regulatory authorities will order expensive changes to landfills after they have been constructed.

Having good technical advice, given by people familiar with the realities of coal-fired generation as well as those of CCR landfill design and operation, can help with the implementation of this complex new CCR Rule. ■

—Veronica Foster, PE ([email protected]) is an associate and senior consultant in the Mount Laurel, N.J., office of Golder Associates Inc.