Condensate polishers add operating reliability and flexibility

Condensate polishers are resin-based ion exchange systems that are commonly used in power plant condensate systems to remove dissolved contaminants (chlorides and silica) and suspended contaminants (iron or copper oxide particulates). Polishers maintain cycle purity and efficiency by controlling the effects of corrosion transport, condenser cooling water leaks, and condenser air in-leakage. Polishers do not make a system immune to chemistry issues, but they do lessen the impact of chemistry problems and often allow a plant to continue operating with a minor condenser tube leak or air in-leakage problem that might otherwise require an immediate outage.

In addition, condensate polishers are suitable for operation with high-performance chemistry programs such as all-volatile treatment (AVT) and oxygenated treatment (OT), they may accelerate plant start-up by minimizing chemistry holds, and they may allow a more orderly plant shutdown in the case of a significant water contamination.

Two basic types of condensate polishers are commercially available: deep- or mixed-bed and precoat condensate polishers. The two types have very different designs and are intended to address site-specific water quality issues found in the power industry.

Option 1: Deep-bed condensate polishers

A deep-bed polisher is typically employed in applications requiring very pure condensate, where it’s vital to remove every trace of contamination. This polisher contains a mixture of cation and anion resin beads in a bed about 3 to 4 feet deep. The resin mixture can consist of varying cation-to-anion resin ratios, depending on the amount of dissolved contaminants expected, with 2-to-1 and 1-to-1 resin ratios being the most common.

Due to the large volume of resin present, the ion exchange capacity of this type of polisher is high; however, its filtering capability is limited. Large quantities of total suspended solids can cause plugging and high pressure drop issues in deep-bed condensate polishers. Filtered particles may also cause fouling of the resin, particularly the anion resin beads, and loss of polisher efficiency (Figure 1).

1. Going deep. This spherical vessel deep-bed condensate polisher system was installed at a once-through pulverized coal-fired power generating facility. Courtesy: Bechtel Power Corp.

Deep-bed condensate polishers are favored in applications where high levels of total dissolved solids (TDS) are present (such as those using sea or brackish waters), where the plant must continue operation with small condenser leaks, and at plants that have minor air in-leakage control problems.

Nuclear power plants normally require deep-bed condensate polishers because their steam systems are sensitive to even minimal levels of contamination. The extremely low cation conductivity limits (<0.15 µS/cm) associated with operation on OT chemistry also call for deep-bed condensate polishers in supercritical and ultrasupercritical plants. Also, EPRI’s latest AVT guidelines recommend condensate polishers on most high-pressure units, advocating that they maintain steam cation conductivity of <0.15 µS/cm.

When the ion exchange capability of a deep-bed condensate polisher is exhausted, the resin beads are cleaned and regenerated with sulfuric or hydrochloric acid and sodium hydroxide. The regeneration process may be external to the service vessels in an on-site regeneration station, in-situ in the service vessels, or off-site at a subcontractor’s regeneration facility, depending on site-specific issues.

On-site external regeneration is the most common technique used today for deep-bed condensate polishers. The resin is sluiced out of the service vessel using water or water and air before being transferred to an on-site regeneration station. The cation and anion resin beads are separated into different regeneration vessels, dosed with dilute acid and caustic to restore the resin’s ion exchange capability, rinsed to remove the residual chemicals, and then recombined.

Resin can also be regenerated in-situ by segregating the cation and anion resins right in the vessels, although the resulting level of polisher performance is usually lower due to cross-contamination of the resins. For instance, externally regenerated polishers typically have a sodium leakage of 3 µg/l or less, whereas an in-situ regenerated polisher may have a sodium leakage as high as 10 µg/l.

Another deep-bed condensate polisher option, which has been gaining popularity in recent years because of its reduced capital cost, is off-site regeneration. In this case, a service company removes the resin from the site, regenerates the resin at its facility, returns it to the site, and reinstalls the resin. However, costs increase with distance from the service company, as transportation costs are a major factor in the price of this service. Off-site regeneration does eliminate concerns with chemical storage and handling and wastewater neutralization and disposal.

The final option is to rent the polishers. Rental polishers are frequently used during commissioning and start-up, when the plant doesn’t have a permanent condensate polisher. Pressure and flow limitations on rental units normally restrict their use to partial-flow side-stream applications recirculating treated effluent to the condenser hotwell.

Option 2: Precoat condensate polishers

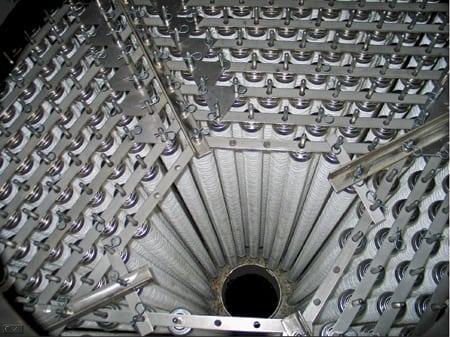

Precoat condensate polishers use a thin coat of powdered ion exchange resin applied to specially designed retaining elements called septa to treat the condensate stream. To create the powdered resin mixture, resin beads are ground to about 200 mesh and mixed with a fibrous fill media. The powdered resin mixture is blended with water to create slurry that is applied to the septa to form a â…›- to ¼-inch precoat layer (Figure 2).

2. Coat of many layers. In this vessel with multiple internal filter elements, slurry of powdered ion exchange resin was applied to condensate polisher filter elements. Courtesy: Graver Water Systems

This thin coat of resin will remove some dissolved contaminants from the condensate, but its capacity is quite limited due to the small quantity of resin used. However, the elements do extremely well at filtering suspended particles from the condensate. Once the precoat condensate polisher is loaded with suspended solids or the ion exchange capacity is exhausted, the spent material is backwashed off the septa to waste and is replaced with a fresh layer. Figure 3 depicts a typical powdered resin application system design for precoat condensate polishers.

3. Slurry delivery system. A simplified flow diagram of a powdered resin mix and coating system. Source: Bechtel Power Corp.

The most common filtration devices used upstream of deep-bed condensate polishers are precoat-type filters, pleated septa filters, and hollow fiber filters. Precoat filters, also called candle filters, are very similar to precoat condensate polishers except that a ground cellulose fiber is coated on the filter elements instead of powdered ion exchange resin. This filtration approach is relatively inexpensive but quite effective when the suspended solids loading in the condensate is low. These filters are also able to remove oil and other insoluble organics from the condensate stream in addition to particulates. Because precoat filters must be recoated each time the differential pressure limit is reached, high particulate loadings can make this type of filter expensive. Effectiveness of the filter can also vary depending on the success of the precoat application.

Filter early and often

A condensate polisher can also be invaluable on combined-cycle plants where the steam turbine original equipment manufacturer (OEM) includes a warranty limit (commonly around 0.2 µS/cm) for the cation conductivity of the low-pressure steam. The cation conductivity of this stream is typically 0.5 to 0.6 µS/cm due to carbon dioxide absorption in the water, which makes the OEM-imposed limit very challenging to meet. A condensate polisher will remove carbon dioxide in the form of carbonates and bicarbonates from the cycle.

Combined cycles used as cycling units have special water treatment challenges: They must balance the EPRI- and OEM-recommended chemistry action levels against guaranteed start-up times. A condensate polisher can be used on these units to reduce the level of contaminants in the steam/water cycle and ensure that chemistry limits do not play a major role in delaying unit start-up times.

Also, any steam plant with a drum pressure greater than 2,400 psia will easily vaporize boiler water contaminants such as sodium and chloride and carry them over to the steam turbine system, rather than leaving them in the boiler drum. This tendency will limit the effectiveness of blowdown as an easy chemistry control practice on drum units and lower the amount of condenser in-leakage that can be tolerated without rapidly increasing blowdown or shutting down the unit. Once-through boiler designs with main steam throttle pressures in excess of 3,600 psia must also use a polisher to maintain system cleanliness.

Air-cooled condensers (ACC) also present unique challenges for the water treatment plant designer. An ACC features a very large surface area to efficiently condense turbine exhaust steam, but the surface area can also upset the steam/water cycle chemistry balance. New ACCs are difficult to thoroughly clean and tend to contribute high levels of contaminates into the condensate during initial commissioning.

Condensate filters are usually included to remove oil and suspended solids from the condensate before the polisher to prevent the loss of efficiency and bed fouling problems. Filters are also recommended when high levels of iron are expected in the condensate return of an export steam system.

Finally, reclaimed wastewater is an attractive option for power plant cooling water systems in regions with limited freshwater for power plant use. The most commonly encountered reclaimed or graywater source is municipal sewage that is treated via a secondary and/or tertiary process. Though the TDS content of graywater is not as high as that of brackish or seawater, the risk of contaminating the steam/water cycle remains significant. A polisher provides protection to allow the unit to initiate a safe and orderly shutdown in case of a leak.

Making the best choice

So far we have surveyed the technology and several technical factors that affect the decision to invest in a condensate polishing system. This discussion raises an interesting question: Is it possible to assess the need for a condensate polisher based simply on high-level plant design data?

We believe the answer is ”yes” and present a decision tree for selecting condensate polishing equipment that we find useful in our work. The decision tree uses a series of primary and secondary technical factors to arrive at a polisher solution (see sidebar). The decision tree is primarily a screening tool; final purchase decisions must be weighed against the specifics of a plant site, makeup water, and first-cost and life-cycle cost considerations.

Bechtel Power has been involved in many condensate polisher evaluations during the past few years. Below, we share five project case histories that illustrate how our condensate polisher selection guide (Figure 4, in sidebar) was used on particular projects. These case histories also illustrate how additional plant design criteria and owner preference will enter into the final selection decision.

Case history #1. Two new 855-MW base-loaded pulverized coal-fired units on a greenfield site in the midwestern U.S. use a once-through supercritical boilers with a 3,700 psia throttle pressure. The units were designed to be commissioned on AVT chemistry and transition to OT chemistry once the cation conductivity of the feedwater was consistently below 0.15 µS/cm and the units had reached a stable operating load. Cold-lime-softened river water was the makeup water source for the plant’s cooling tower. The plant was designed to internally recycle as much of its own wastewater as possible, but it has a permit that allows discharge of some wastewater from the plant to a nearby river.

The selection guide determined that a deep-bed condensate polisher was required. The plant water balance included significant internal wastewater recycling in the wet flue gas desulfurization (FGD) system and as ash-conditioning water. The remainder went to an outfall. External regeneration was selected due to the high-quality condensate required for OT operation. The final design used 3 x 50% service vessels for each of the two units with a common, centrally located regeneration station to minimize capital costs.

Case history #2. A new 450-MW base-loaded pulverized coal-fired unit on a site with two existing units in the southwestern U.S. uses a drum boiler design with a 2,400 psia throttle pressure. The unit was designed to operate on an AVT chemistry program with phosphate injection available for emergency use only. Cold-lime-softened well water is the makeup water source for the plant’s cooling tower. All nonrecyclable wastewater is treated in a zero-liquid-discharge (ZLD) system and disposed of in on-site evaporation ponds.

None of the five primary factors in the selection guide applied to this unit, but secondary factors did: the throttle pressure, a steam cation conductivity limit of 0.2 µS/cm, and a condensate system designed to operate on AVT chemistry. Based on the selection guide, a precoat condensate polisher was selected for this project. The final design provided for 2 x 100% precoat polisher service vessels.

Case history #3. A 2 x 1 combined-cycle power plant with a 1,880 psia throttle pressure located in the UK was designed for a phosphate chemical treatment program. The plant was expected to be routinely cycled and was designed for rapid start-up. The turbine exhaust steam was cooled with an ACC.

None of the selection guide’s primary selection factors came into play, and only two of the secondary factors were present, so no condensate polisher was required. However, based on the owner’s preference, a 1 x 100% precoat condenser polisher was included as part of the plant design. The precoat polisher was selected because of its ability to handle the high levels of iron transport associated with an ACC operating in cycling service. The potential for carbon dioxide in the condensate, due to air in-leakage in the ACC, was another key factor in its selection.

Case history #4. Two new 750-MW base-loaded pulverized coal-fired units on a site with one existing unit in the midwestern U.S. use a once-through 3,700 psia supercritical design. The units were designed to be commissioned on AVT and to transition to OT chemistry once cation conductivity of the feedwater was consistently below 0.15 µS/cm and the units had achieved a stable operating load. Cold-lime-softened well water is the cooling tower makeup water source. The plant uses a ZLD system with all nonrecyclable wastewater disposed of in on-site evaporation ponds. Minimal opportunities for wastewater recycling exist within the facility because a dry FGD system and production of saleable ash were part of the overall plant design.

The selection guide determined that a deep-bed condensate polisher was best for this plant. However, because the plant has a ZLD system and minimizing wastewater was a key project design goal, off-site regeneration of the polisher resin was selected. The final design used 3 x 50% vessels for each of the two units with a common, centrally located resin transfer and storage station to minimize capital costs. The resin storage facilities were designed to store three charges of fresh resin—one spare charge for each new unit plus one extra charge.

Case history #5. Two new 750-MW base-loaded pulverized coal-fired units on a greenfield site in the southwestern U.S. use once-through supercritical boilers operating at 3,690 psia. The units were designed to be commissioned on AVT, with the transition to OT chemistry occurring once cation conductivity of the feedwater was consistently below 0.15 µS/cm and the units had achieved a stable operating load. The plant recycles large amounts of internal wastewater to the wet FGD system and as ash-conditioning water. High-quality well water is available for plant cooling water on a limited basis. Therefore, a hybrid wet-dry cooling system was planned for this facility. The hybrid design includes an ACC as well as a wet mechanical draft cooling tower to minimize water usage while maximizing cooling capability and unit efficiency.

The selection guide pointed to the choice of a deep-bed condensate polisher. Internal water recycling capability indicated that on-site regeneration of the polisher resin would make economic sense. The final design used 3 x 50% service vessels for each of the two units with a common, centrally located regeneration station to minimize capital costs. Because the design included an ACC, pleated septa condensate filters were included upstream of the deep-bed polisher vessels to protect the deep-bed polishers from high levels of particulates during start-up. These filters could be bypassed during normal operation once condensate cleanliness is established.

—Colleen M. Layman ([email protected]) is manager of water treatment engineering, and Lisa L. Bennett ([email protected]) is a water treatment engineer for Bechtel Power Corp.