Coal Ash Mapping Using Electromagnetic Technology

The identification and containment of coal ash has risen to the top of the priority list for plant managers across the U.S. after inadvertent releases of coal ash into unintended areas resulted in adverse environmental impacts and negative publicity. Increased scrutiny and changing regulatory requirements are forcing plant operators to work aggressively to manage coal ash.

Looking for Trouble

In the past, utilities used exploratory excavations, hand augering, and test drilling to determine if coal ash basin containment structures had failed and to identify the extent of coal ash deposits, which do occasionally fall outside of intended boundaries. These traditional methods of coal ash exploration are labor-intensive, time-consuming, and can be inaccurate due to the physical constraints of the process.

However, an innovative new method utilizing frequency domain electromagnetic (FDEM) induction surveys has been employed to scan soil at coal-fired plants to provide improved underground characterization of subsurface strata. The response from plant operators, who have been looking for more efficient and definitive tools to characterize subsurface conditions, especially when unintended coal ash is involved, has been very positive.

The FDEM method is attractive for generators because it is less expensive than traditional physical work and the results are highly reliable. Some studies have determined that using electromagnetic technology rather than traditional subsurface exploration techniques is 85% more economical, and results are available in less than a quarter of the time.

Conductivity and Magnetism Provide Answers

The utilization of the FDEM method at coal ash sites identifies the lateral extent of the potential coal ash flow. Coal ash contains the mineral pyrite (iron disulfide), which is very conductive and magnetic, thus resulting in lateral changes in subsurface conductivity when coal ash is present.

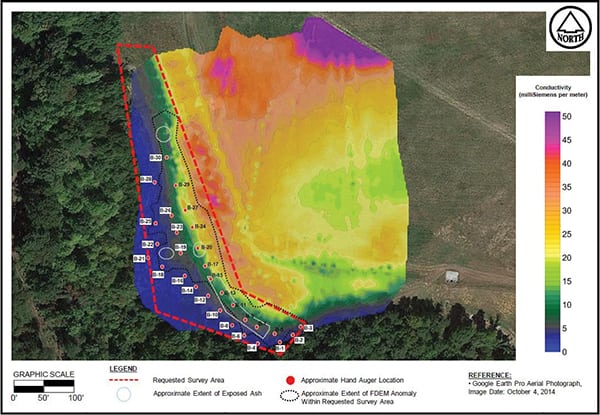

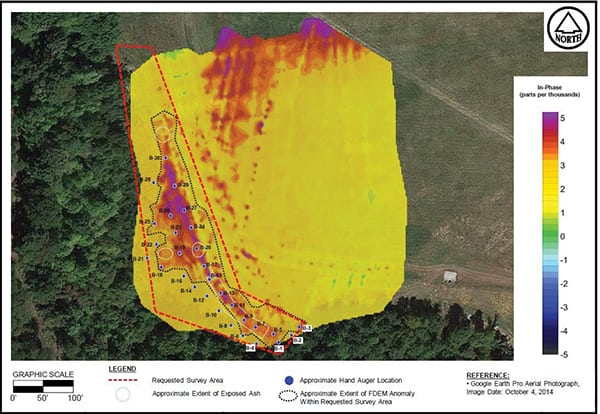

FDEM measurements provide a noninvasive method (Figure 1) for the measurement of subsurface conductivity and magnetic susceptibility. The mapped conductivity and susceptibility contrasts (Figures 2 and 3) delineate the approximate lateral extent of the coal ash.

|

|

2. Painting the picture. Bulk conductivity maps depict, by color, the magnitude and concentration of coal ash. Courtesy: Paul Boyadjian |

|

|

3. Seeing results. In-phase data from the frequency domain electromagnetic survey depicts differing conductivity within the soil. Courtesy: Paul Boyadjian |

During initial trials of the FDEM method, hand augering was conducted both inside and outside of coal ash boundaries to verify results. The plots generated using FDEM were confirmed to be highly accurate.

“Our clients have been very pleased with the results of the FDEM execution as quantitatively verified by the hand augers,” said Todd Eiler, project manager and president of Eiler Services. As a result, the use of hand augers has not been required on subsequent projects.

The FDEM method allows fast data acquisition in a fraction of the time of previous methods. In short, data can be collected as quickly as a person holding a conductivity rod can walk. The depths at which FDEM technology can be deployed are dependent on the length of the conductivity rod, with the standard length being 12 feet. The sole prerequisite is that a walkable, unobstructed route is required to complete the grid pattern.

Enhanced Results

With the success of FDEM, utilities have undertaken other electromagnetic technology applications to characterize subsurface conditions, such as 2-D multichannel analysis of surface waves, electrical resistivity imaging, and seismic refraction. Plant owners may implement multiple complimentary geophysical methods to attain more accurate subsurface data given the sometimes-complex nature of geophysical conditions.

As with most types of technology in this arena, there are limitations associated with each method, and the results need to be considered appropriately. Therefore, using multiple complimentary geophysical methods is sometimes preferred so that a more accurate subsurface model of the site conditions can be developed. Each technology can be used independent of the other or can be combined with others to provide more definitive results when one method alone does not suffice.

The value of FDEM continues to grow as this type of technology is being deployed at sites to identify the location of underground items such as concrete, metal pipes, large boulders, subsurface voids, conduits, and more. These innovative tools are also being deployed to perform geophysical surveys. These surveys allow the subsurface variability to be better understood, improving the accuracy of models prior to any site work or physical excavations.

Furthermore, FDEM applications can be utilized anywhere subsurface conditions are crucial to the success of a project. Given the age of many facilities and the accuracy of existing data, some utilities now mandate the use of ground-penetrating radar prior to excavation. In many cases, this is an overly conservative method yielding less-than-perfect results. Given the major technological advances in electromagnetic exploratory tools and methods, utilities now have a superior option to traditional toolsets.

—Paul Boyadjian, PE, PMP ([email protected]) has served as director of engineering and vice president of engineering at various firms involved in engineering, procurement, and construction projects.