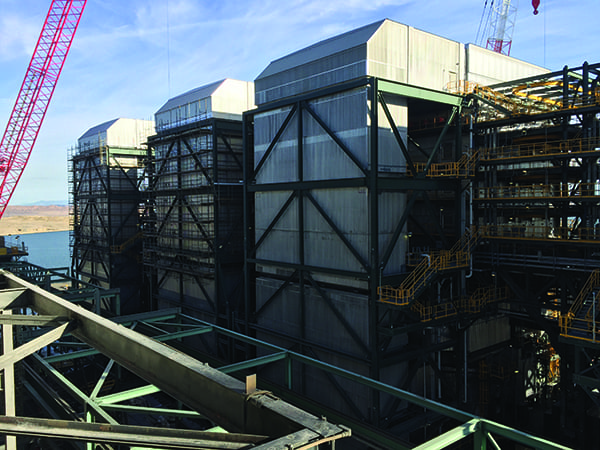

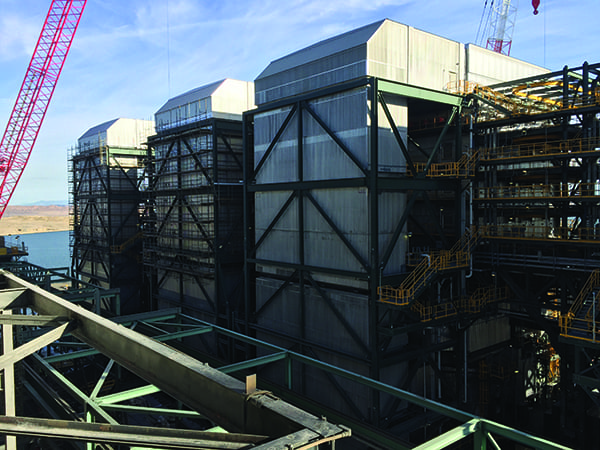

The numbers tell the story of how the addition of selective catalytic reduction (SCR) technology helped an iconic New Mexico coal-fired plant reduce its emissions, keeping the plant in operation…

Technical articles on all aspects of power plant operation, preventive and predictive maintenance, planned and unplanned outages

The numbers tell the story of how the addition of selective catalytic reduction (SCR) technology helped an iconic New Mexico coal-fired plant reduce its emissions, keeping the plant in operation…

Shutdown, turnaround, and outage events are extremely complex, with multiple stakeholders all focused on minimizing the time assets are offline, delivering their scope on budget, and ensuring zero safety incidents.…

Lebanon, Pennsylvania – July 24, 2019 | Marsulex Environmental Technologies (“MET”) has announced the award of a contract for flue gas desulfurization (FGD) systems by an Indian government power company…

BrandTech™ Precast Solutions deliver results to customers 90% faster Kennesaw, Georgia, USA, July 25, 2019 (GLOBE NEWSWIRE) --Industrial Specialists by BrandSafway recently added a hot wire CNC (computer numerical control)…

ABB is partnering with Enel Green Power to deliver innovative predictive maintenance solutions that will lower maintenance costs and transform the performance, reliability and energy efficiency of its hydropower plants…

B&W’s Submerged Grind Conveyor enables realization of operation efficiencies and maintenance costs improvements not available with traditional high-pressure sluice systems Design also helps customers meet proposed Coal Combustion Residual rules…

![Lithium-Ion Batteries: Costs Down, Benefits Up [PODCAST]](https://www.powermag.com/wp-content/uploads/2018/10/power-podcast-art-final.jpeg)

The price of lithium-ion batteries has plummeted over the past decade. Battery pack prices averaged $1,160 per kWh in 2010, according to BloombergNEF, but they dropped to $176 per kWh…

The rapid proliferation of dreissena rostriformis bugensis—the quagga mussel—has major implications for power plant reliability. The U.S. Bureau of Reclamation installed a groundbreaking solution at Parker Dam in Arizona that…

Ultrasonic nondestructive testing, also known as ultrasonic NDT or simply UT, is a method of characterizing the thickness or internal structure of a test piece using high-frequency sound waves. The…

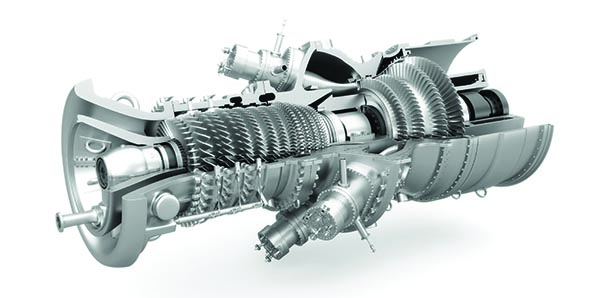

Industrial gas turbine (IGT) manufacturers and maintenance, repair, and overhaul (MRO) personnel are continually seeking new ways to improve the performance and longevity of critical components. High-value components must be…