The world’s first autonomous combined cycle power plant is currently under construction at the Takasago Machinery Works facility in Japan, and it will be operational by 2020, according to Mitsubishi…

Coverage of every aspect of gas-fired power plant design, construction, and O&M, including combined cycles, HRSGs, cogeneration, and LNG.

The world’s first autonomous combined cycle power plant is currently under construction at the Takasago Machinery Works facility in Japan, and it will be operational by 2020, according to Mitsubishi…

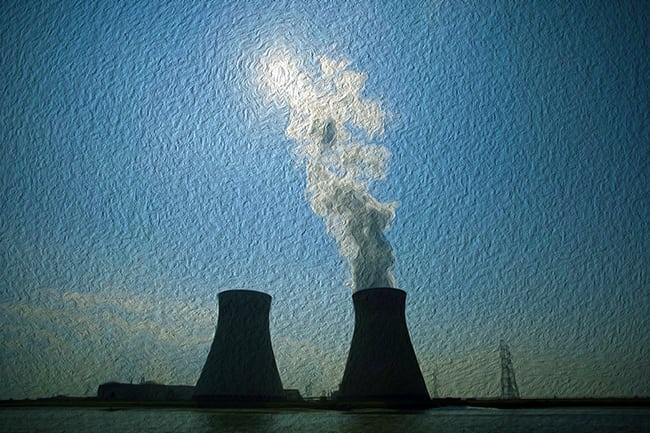

The Netherlands Orders Early Closure of Coal Plants The Dutch government on March 8 told Swedish power producer Vattenfall to stop using coal at the 650-MW Hemweg-8 hard coal-fired unit…

Ever since deregulation came to the power industry, combined cycle plant managers have been trying to benchmark their production metrics and cycling costs against those of their competitors. There has…

Attemperation equipment is necessary to control steam temperatures at many power plants. However, when the equipment functions improperly or the design is flawed, thermal quenching/shock can damage piping. Proper inspections…

Boiler feedwater valves operate under severe service conditions and are subject to premature failure from seat leakage, cavitation, particulates, and frequent cycling. However, once the type and root cause of…

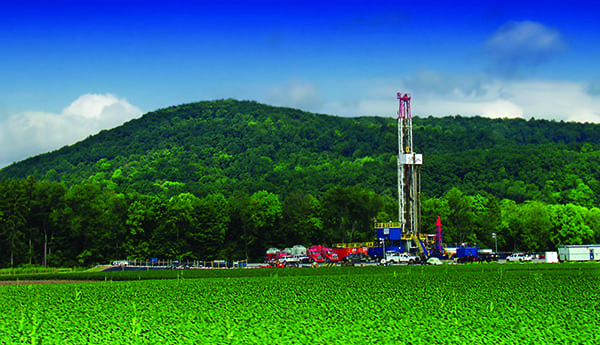

Demand growth for natural gas for power generation may have slowed in the U.S., as renewable resources continue to take market share. With U.S. production continuing to hit record highs,…

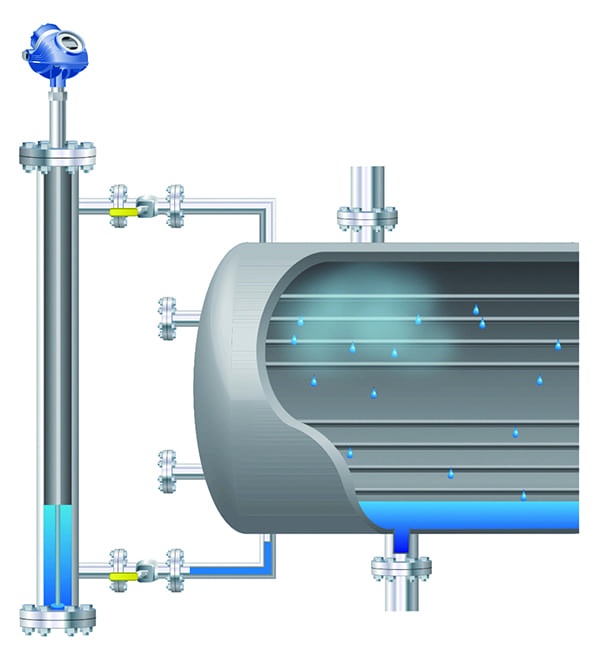

The right level instrumentation is key to keeping boilers on an even keel. Guided-wave radar offers a critical combination of capabilities. If asked to make a short list of factors…

Comparing the costs of differing electric generating technologies has become popular among advocates for particular technologies and those seeking to find the optimal approach to new generation. While getting attention…

The Umm Al Houl combined cycle power plant in Qatar has been inaugurated by Siemens, delivering almost a quarter of the country’s installed power generating capacity and providing up to…

Strategic Partnership Agreement signed Technology collaboration agreement in heavy-duty gas turbines Siemens AG and State Power Investment Corporation Limited (SPIC) signed a comprehensive Strategic Partnership Framework Agreement (SPFA). This follows…