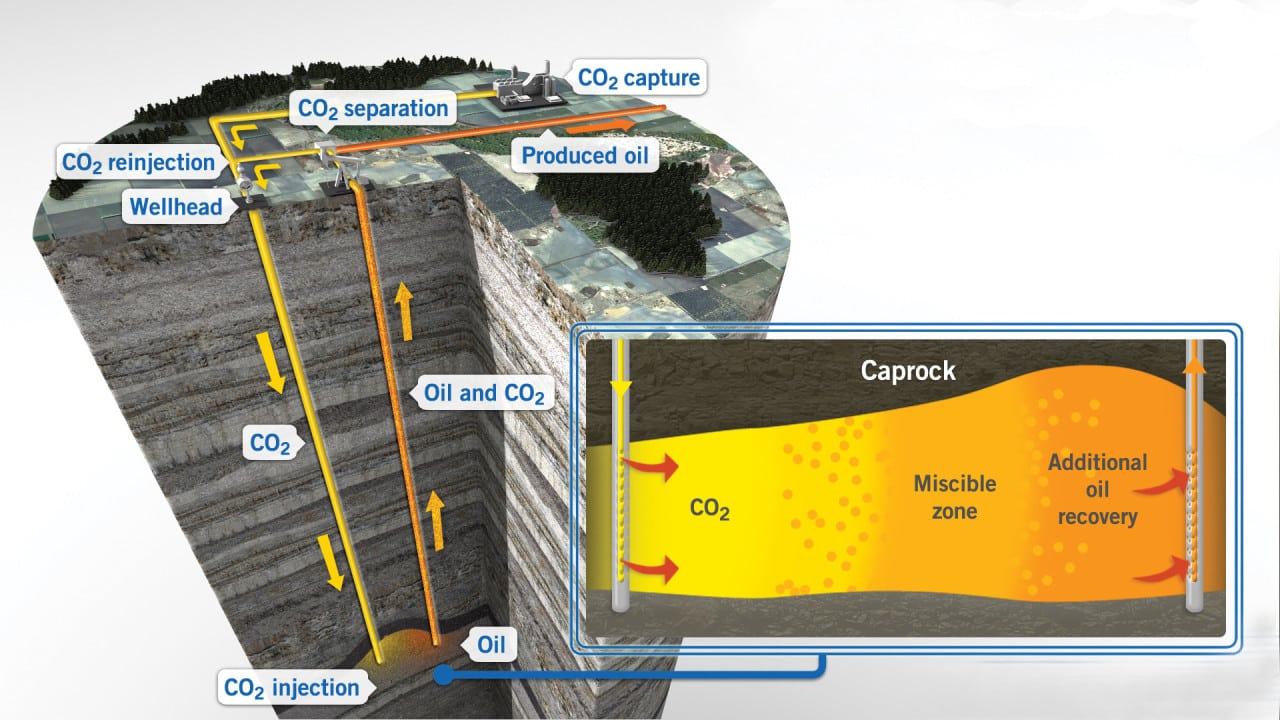

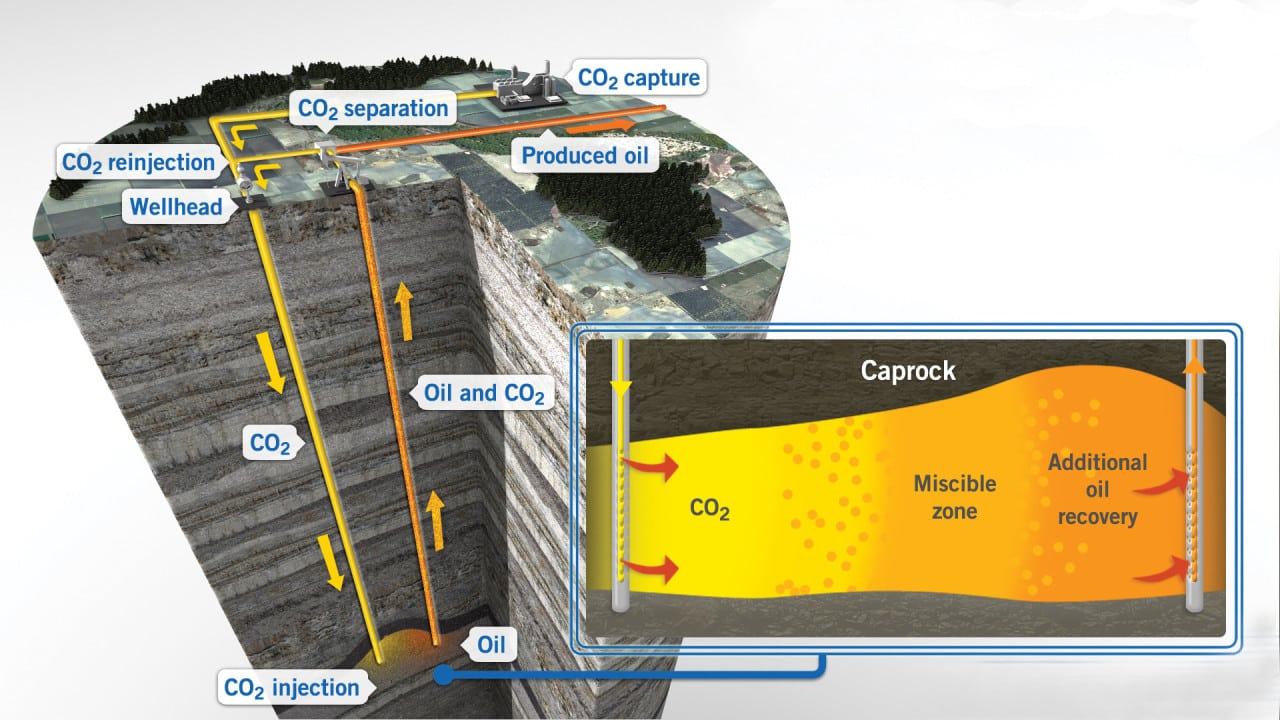

In April’s editorial, “When Technology Tails Wag Power Dogs,” Editor Gail Reitenbach mused about whether the use of captured carbon dioxide (CO2) for enhanced oil recovery (EOR) represents a viable…

Coal power plant design, construction, operation and maintenance, as well as legal and regulatory issues.

In April’s editorial, “When Technology Tails Wag Power Dogs,” Editor Gail Reitenbach mused about whether the use of captured carbon dioxide (CO2) for enhanced oil recovery (EOR) represents a viable…

After 64 years as a landmark in Wilmington, N.C., one of three boiler units at Duke Energy's retired coal-fired L.V. Sutton Plant crumpled in a dusty heap of contorted steel…

The average capacity factor for U.S. natural gas–fired combined cycle power plants (CCPPs) exceeded that for coal-fired plants in 2015 for the first time since the Energy Information Administration (EIA)…

Multiple international news organizations have reported that at least four people were killed, and as many as 100 more were injured, when police opened fire on an estimated 1,500 villagers…

In what has become a regular occurrence with the Kemper County integrated gasification combined cycle power plant, Mississippi Power announced in a filing with the Securities and Exchange Commission on…

Researchers at the Massachusetts Institute of Technology (MIT) have combined two proven technologies to create a new hybrid system that could produce electricity, using coal as a fuel source, at…

Setting the stage for a drawn-out fight with ratepayer groups and other generators, the Public Utilities Commission of Ohio (PUCO) on March 31 approved proposals from FirstEnergy and American Electric…

Saudi Arabia Mulling Privatization of State-Owned Utility. State-controlled Saudi Electricity Co. (SEC) is to be split into four power generation firms by the end of 2016 to increase efficiency, Abdullah…

Vietnam, which has long been a coal exporter, is considering a hiatus in licensing new coal-fired power plants because it says domestic coal reserves won’t be enough to feed generators…