Biofuels help green up gas turbines

It’s a common perception that environmentally friendly practices are inhospitable to company bottom lines. However, the lean, premixed, prevaporized (LPP) combustion of liquid fuels, also known as LPP gas, offers substantial financial savings to power plant operators when a cheaper fuel (relative to natural gas) is used to power gas turbines. In addition, in light of the growing number of carbon emission regulations in many states, this technology has the advantage that it can use renewable fuels, which produce clean power with no net greenhouse gases and earn carbon credits for the generator.

The new LPP System provides an alternative fuel source for gas turbines designed to use natural gas. It creates, in effect, a substitute natural gas. The transition between the use of natural gas and LPP gas is virtually transparent to the gas turbine operator. The physical transition process may be made in minutes while the turbine continues to spin. The turbine may be operated on pure natural gas, pure LPP gas, or any blend of LPP gas and natural gas. To date, development of this technology is so recent that it is not yet being used by any power plants.

“The discussions for the first power plant installation are currently ongoing, with interest from various size facilities all around the country,” Dr. Richard Roby, CEO of LPP Combustion, said in an interview with POWER in April. “The design of the first commercial-scale unit is being finalized in order to have it constructed and operating around the end of 2008. This LPP System is designed for a mobile 5.5-MW gas turbine that will allow the technology to be showcased at a variety of locations using a variety of liquid fuels, including biofuels.”

The real deal: Gas derived from biofuels

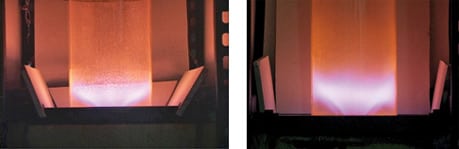

The heating value of LPP gas is tailored to approximately match that of natural gas. The only notable difference between natural gas and LPP gas is the requirement that LPP gas be maintained at a temperature high enough to ensure that none of the liquid fuel condenses before reaching the combustor, according to Dr. Leo Eskin, LPP Combustion’s president. The required fuel temperatures are similar to those already proven for integrated gasification combined-cycle plant operation. Figure 1 presents a comparison of a natural gas flame and a flame produced using the LPP System and biofuels.

1. The same flame. A lean, premixed natural gas flame (left) and lean, premixed, prevaporized biodiesel flame (right) look very similar. Courtesy: LPP Combustion LLC

“For essentially all liquid fuels of interest (including biodiesel, ethanol, kerosene, and ultra-low-sulfur diesel), the criteria pollutant (NOx, CO, or particulates) emissions levels remain equal to that of natural gas; therefore, there is no need for steam or water additions to the LPP System,” Eskin told POWER. “The LPP System is comprised of standard components, such as heat exchangers and compressors, allowing the variable maintenance costs to be minimal and consistent with power industry equipment.”

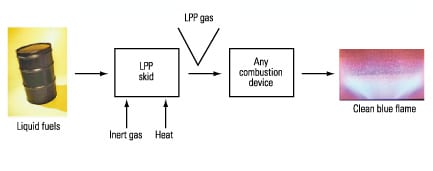

When burning LPP gas derived from ethanol or biodiesel, the combined-cycle net plant output is expected to be reduced by less than 0.5%, when compared to conventional liquid fuel operation burning No. 2 fuel oil (Figure 2), and is expected to be reduced by less than 2.5% when compared to natural gas operation

2. Improved fuel burning. Conventional liquid fuel spray diffusion flame (left) and typical lean, premixed gas (LPP) flame (right). Courtesy: LPP Combustion LLC

Easy integration with existing hardware

There don’t appear to be any technical challenges to the widespread use of the LPP System at U.S. power plants that currently use gas turbines with natural gas-burning capabilities. The new system, with the exception of the fuel vaporizer, utilizes proven components that are commonly found in power generation equipment.

“The LPP System does not affect how the gas turbine functions. In essence, the LPP System is a fuel preparation and delivery system, and it delivers fuel to the turbine just as the existing fuel systems for natural gas or liquid fuels,” Dr. Michael Klassen, LPP Combustion’s chief technical officer, explained to POWER. “By vaporizing the liquid fuel in an inert environment prior to it entering the combustion system, typical problems associated with liquid fuels, such as autoignition and increased wear and maintenance, are avoided. There are no mechanical difficulties associated with using the LPP gas.”

The LPP System is a skid-mounted fuel-conditioning system and can be installed either in an integrated or stand-alone mode, according to Klassen. The vaporized fuel leaving the LPP System is connected to the turbine’s existing fuel system; therefore, no hardware modifications to the turbine are necessary. The skid can be packaged in a variety of configurations, depending on the amount of available space near the turbine.

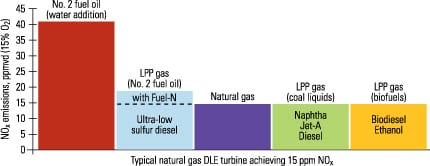

Installing the LPP System at a plant that opts to use LPP gas in addition to natural gas shouldn’t present any major financial challenges. The LPP System falls in approximately the same price range as the back-end pollution control equipment required when burning traditional liquid fuels—equipment that’s not needed with the LPP System because LPP gas produces lower emissions (Figure 3).

3. Simple in concept. The lean, premixed, prevaporized combustion process diagram. Source: LPP Combustion LLC

Big bang for the buck

There are already many situations in which the LPP System is financially competitive with power plants that use natural gas. These include regions where natural gas can be curtailed or is difficult to obtain. Furthermore, the LPP System allows the gas turbine owner to generate renewable electric power when biofuels such as ethanol and biodiesel are used.

“The ability to provide dispatchable renewable energy is highly valued, as many regions are requiring that as part of their energy portfolio,” Michael Ramotowski, LPP Combustion director of operations, said a recent interview. “It is challenging to forward price the cost of biofuels, but we believe it is reasonable to assume that advances in biofuel production methods will make the LPP fuel cost even more financially competitive in the near future.”

A significant feature of the LPP System is the ability it gives plant operators to switch between natural gas and liquid fuels on the fly. This capability is important to plants, because it will allow them to select their fuel based on economic drivers or fuel availability.

“For example, if natural gas availability is curtailed (as happens often in locations such as the U.S. Northeast during winter months), generators can switch to liquid fuels and continue to operate,” Ramotowski said. “This capability also provides the generator a physical hedge on fuel prices, allowing the operator to literally switch fuels, depending on the delivered price. A huge benefit of the LPP process is that the switch in fuel can be accomplished without any sacrifice in pollution level.”

Regulations drive increased biofuel use

Recently, many states have enacted renewable portfolio standards (RPSs) requiring that a specified percentage of electric power generated come from renewable energy sources—such as wind, solar, or biofuels—by a given date. For example, Texas is expected to avoid 3.3 million tons of CO2 emissions annually with its RPS, which requires 2,000 MW of new renewable generation by 2009. (For more information about RPSs, go to the U.S. Department of Energy’s Energy Efficiency and Renewable Energy Distributed Energy Program’s Web site: www.eere.energy.gov/de/renewables_portfolio_standards.html.)

By converting biofuels, such as biodiesel or ethanol, into a synthetic substitute for natural gas, the LPP System can help power plants achieve the same low emissions as they would by burning natural gas, while delivering the additional benefit of having “net zero” carbon emissions. (For a potential downside to using biofuels,see the sidebar.)

“Using biofuels with the LPP System and a gas turbine creates a dispatchable renewable energy generator that is more reliable than solar or wind power technologies and can help states meet their renewable portfolio standards by providing renewable energy on demand,” Ramotowski said. “The LPP System also has the advantage of being able to use existing gas turbine and power grid infrastructure to create a low-cost and clean renewable energy generator.”

In addition to RPSs, there is a growing movement in the U.S. toward enacting cap-and-trade programs for carbon emissions, such as the recent initiatives passed in several different regions of the country. For example, the Regional Greenhouse Gas Initiative (RGGI), which includes 10 states in the Mid-Atlantic and Northeast, is a strong driver for promoting the use of LPP combustion technology using biofuels.

“The first RGGI auction for carbon allowances is this coming September. Forward trades for carbon have already taken place under the RGGI system. Several western states have a similar initiative for a carbon cap-and-trade program but are not as far along as RGGI,” Roby said. “The LPP System using biofuels creates a reliable and dispatchable renewable energy generator that can help states meet both their renewable portfolio standards and carbon cap restrictions.”

Looking down the road

Today there is significant interest in using biofuels in combustion devices to produce renewable energy with no net carbon emissions. However, the traditional method of burning liquid fuels as a spray diffusion flame is highly polluting and creates significant amounts of criteria pollutants such as NOx, CO, and particulates (PM) (Figure 4).

4. Meets the standards. This chart shows NOx emissions performance for a range of fuels using LPP Combustion technology and a nominal 15 ppmv NOx DLE fuel nozzle and conventional spray diffusion nozzle with water addition. Source: LPP Combustion LLC

“Using biofuels with the LPP System creates a synthetic substitute for natural gas that will play an important role in today’s carbon-conscious world by providing no net carbon emissions and the same low-level pollutant emissions for NOx, CO, SOx, and PM as are only currently generated by natural gas,” Ramotowski said.

Biofuels will become increasingly important in the future as the electric power industry starts switching over to more renewable energy sources. The LPP System is an example of a clean method for burning biofuels for renewable power generation.