ACES Delta's Giant Utah Salt Cavern Hydrogen Storage Project Gets $504M Conditional DOE Loan Guarantee

The Advanced Clean Energy Storage Project, a much-watched project under development in Delta, Utah, that is shaping up to be the largest renewable hydrogen energy hub in the U.S., has garnered a conditional commitment for a $504.4 million loan guarantee from the Department of Energy’s (DOE’s) federal loan guarantee program.

The conditional loan guarantee commitment issued on April 26 is for the Advanced Clean Energy Storage I, the first phase of a massive undertaking by ACES Delta, which is a joint venture comprising Magnum Development (Magnum), Mitsubishi Power, and Haddington Ventures, to create a new pathway for decarbonization of the Western U.S. grid.

The project envisions producing up to 100 metric tonnes per day of hydrogen from water and renewable energy sources using a 220-MW alkaline electrolyzer bank manufactured by Norwegian firm HydrogenPro—one of the largest deployments of its type to date. That hydrogen will be stored in two gigantic solution-mined caverns sited in the only salt dome in the Western U.S.

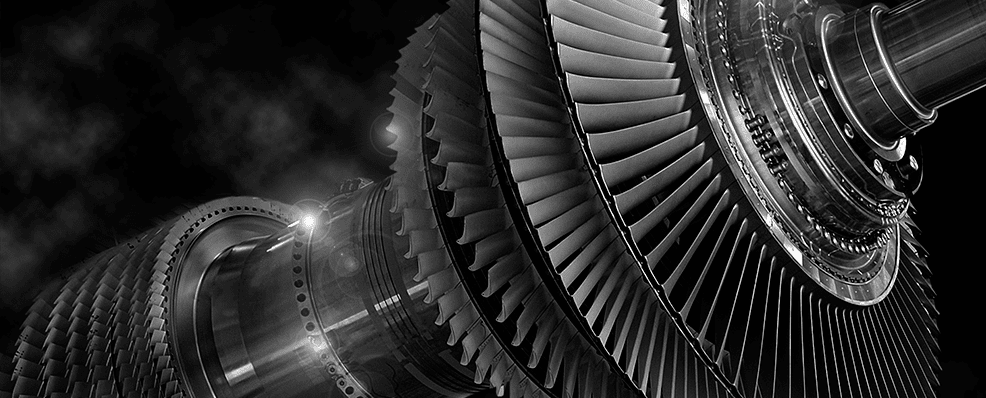

Capable of storing a combined 300 GWh of energy, the storage facility will provide long-term seasonal energy storage to Intermountain Power Plant’s (IPA’s) Intermountain Power Plant (IPP) near Delta, Utah, a coal-fired plant that is slated to be repowered with two Mitsubishi Power advanced M501JAC power trains as an 840-MW combined cycle power plant by 2025.

A Power-to-Power Project

The 1986–opened IPP’s two coal-fired units, a combined 1,800 MW, currently average about 13 TWh each year, power that is delivered over 2.4-GW AC and DC lines to IPA’s 35 municipal utility participants, which are primarily in Utah and Southern California. Catering to state clean energy targets—including California’s 100% clean electricity target by 2045—IPA in 2019 signed a pioneering contract with Lake Mary, Florida–based Mitsubishi Power Americas that commercially guarantees the M501JAC units will be able to combust a mix of 30% hydrogen and 70% natural gas when they come online in 2025. Mitsubishi Power told POWER that progress continues to develop a second-generation combustion system that will enable the JAC units to achieve 100% hydrogen fueling by 2045.

The DOE’s Loan Programs Office (LPO) lauded the project’s selection for its potential to “safely and cost-effectively produce and store hydrogen.” LPO Director Jigar Shah on April 26 noted the selection, which is just one of nearly 80 active applications across a variety of technology sectors submitted to the DOE office since March 2021, supports the Biden administration’s efforts to tamp down renewable hydrogen costs by about $5/kilogram as well as “expand the use of clean hydrogen in the industrial sector and beyond.”

The ACES Delta project becomes the DOE’s third offered conditional loan guarantee under the Biden administration. LPO in December offered a $1 billion conditional loan guarantee to Monolith, a 2012-established firm that has developed a methane pyrolysis process to convert natural gas into hydrogen and high-purity carbon black using renewable energy. On April 18, it offered to conditionally lend up to $107 million to Syrah Technologies to expand its capacity to produce critical materials for lithium-ion batteries at the Syrah Vidalia Facility in Louisiana.

Shah on Tuesday highlighted the ACES Delta project’s potential to reduce curtailment of renewable energy in the Western U.S., as well as reduce criteria air pollutant emissions, such as ozone precursors and particulate matter, as well as greenhouse gases (GHGs). That’s consistent with the primary goal of the Title XVII Program, which was established in the 2005 Energy Policy Act, the DOE noted.

“Financially supporting the Project would help bring hydrogen to market and into greater use, thereby reducing overall national emissions of air pollutants and human-caused GHGs,” it added. However, while the conditional commitment demonstrates the DOE’s intent to finance the project, “several steps remain, and certain conditions must be satisfied before the Department issues a final loan guarantee,” Shah noted on Tuesday.

A Massive and Urgent Undertaking

According to Michael Ducker, senior vice president of Hydrogen Infrastructure for Mitsubishi Power Americas and president of Advanced Clean Energy Storage I, the project (which is referenced by its full name for trademarking reasons) has made rapid progress since its unveiling in May 2019. Since the project was unveiled, ACES Delta has set out to obtain necessary state and local permits and approvals for the project, as well as prepare the project design and cost estimate. The DOE assessed these factors as it made its conditional commitment, Ducker noted.

The ACES Delta project is now in the final stages of debt and equity closing. While Haddington Ventures, the financial advisor for the project and equity sponsor of Magnum Development, is securing $650 million through its Equity Syndication Program, ACES Delta expects financial close of the loan guarantee in the second quarter of 2022, Ducker said.

The hub has also secured all major contracts, including for offtake with IPA, engineering, procurement, and construction (EPC) contractors, as well as major equipment suppliers and operations and maintenance (O&M) providers. Engineering giant Black & Veatch is slated to provide EPC services, while Mitsubishi Power will provide all hydrogen equipment integration, including the 220 MW of electrolyzers, gas separators, rectifiers, medium voltage transformers, and distributed control system. NAES Corp., an O&M service firm, will initially provide the O&M services for the plant and will oversee the current projected team of 20 plant-related personnel. WSP, another engineering giant, will provide EPC management services for the development of the two large salt cavern storage facilities, leveraging decades of experience in its development of more than 200 salt caverns around the world.

Construction Has Begun

These milestones, reached with extraordinary speed for such a massive project, have already allowed ACES Delta to break ground at the project site. “Construction has begun,” Ducker confirmed. “That’s because we’re keeping with the schedule at IPA and the other online date for their power plant, for the hydrogen-capable gas turbines in 2025,” he said.

This year, IPA plans to begin upgrading the IPP with Mitsubishi Power’s M501JAC gas turbines, heat recovery steam generators, and steam turbines in each of the plant’s combined-cycle units. In tandem, Mitsubishi Power’s “multi-cluster” combustor technology that could enable 100% hydrogen combustion at the project’s heavy-duty JAC gas turbines is under validation and will be commercialized at the newly unveiled Takasago Hydrogen Park in Japan. “To sync up schedules with us constructing the caverns and the hydrogen production, we need to start now,” Ducker noted.

Construction of the Advanced Clean Energy Storage project will entail building a hydrogen generation facility, where the electrolyzers will produce and compress hydrogen for delivery and storage in the caverns. The electrolyzers from HydrogenPro (a company in which Mitsubishi Power’s parent company Mitsubishi Heavy Industries (MHI) is an investor) will be housed in above-ground mechanical units with low-profile cooling towers and other associated facilities.

The project also includes the construction of ancillary support facilities, such as the O&M building; an electrical distribution and high-voltage transmission system with a substation and switchyard facilities; water and brine delivery systems with pumps, filtration, and pipelines; standard water treatment facilities to provide demineralized water for the electrolysis modules; demineralized water storage tanks; raw water tanks for process water; firewater storage tanks; cooling towers to support rejection of heat generated during the process; plant instrumentation; and a hydrogen gas delivery system with filtration and dehydration units and quality and flow measurement facilities.

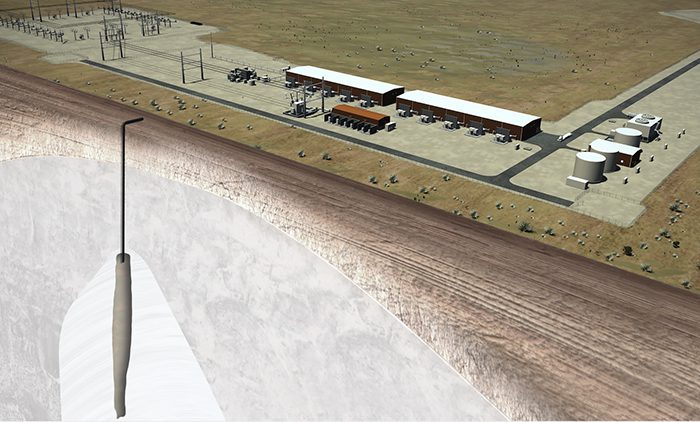

The most time-consuming task within the project construction scope, however, relates to building the two caverns, which are purpose-built and engineered to store hydrogen. The salt dome sprawls over 4,800 acres directly adjacent to the IPP power plant near Delta, Utah. The two storage caverns envisioned as part of the first phase of the Advanced Clean Energy Storage Project will be built about a mile away from the electrolyzers.

“In accordance with the geo-mechanical design, the dimensions of each cavern are anticipated to be approximately 220 feet in diameter and approximately 1,200 feet in height. The tops of the caverns will range in depth between 3,500 and 4,100 feet below the ground surface (bgs), and the bases of the caverns will range in depth from 4,700 to 5,300 feet bgs,” the LPO’s environmental assessment (EA) for the Advanced Clean Energy Storage Project says.

“A salt cavern takes roughly two years to construct,” Ducker said. “The best way to think about that site is as a big block of salt. What we do is drill into that salt with conventional drilling practices,” he explained. “It’s literally just drilling a well down, and then we inject water. Water dissolves salt, and then based on where we put the ‘stringer,’ you basically keep dissolving the salt, bringing that water out, putting new fresh water in.” The caverns will require large evaporation ponds that will contain brine solution. But the technique, while slow, is deliberate, Ducker noted. It “entails no exotic materials,” he said. It’s “literally just time and water.”

The LPO’s EA suggests the project is designed with features that include “equipment and material selection appropriate for the hydrogen gas generation and handling process.” These include minimum distances between certain hydrogen generation and handling equipment, the installation of a facility-wide leak detection and emergency shutdown system, and emergency and fire response and suppression measures. A Safety in Design (SID) analysis and preliminary Process Hazard Analysis (PHA) were also completed for the project’s front-end engineering design. “The analyses were completed to determine the applicable regulatory requirements for

preventative design features and measures and active and passive fire protection systems to incorporate

into the facility design,” the EA says. A final PHA will also be completed as part of the final facility design.

Hydrogen Hub Part of a Larger Vision

Completion of the first phase of the Advanced Clean Energy Storage project will inform future phases, as well as provide more insight on future infrastructure needs for a potential expansion. “We really see this as the first phase of our hub, and so over time, we’re looking to add additional projects,” Ducker said. “Some may be for power applications and long-duration storage, like we’ve got for [the first phase]. They may be for other heavy industries.”

Ducker said that while ACES Delta has focused on “getting this first piece done,” developers have envisioned what the whole site could look like through the next several decades. A “2050 vision” plan, for example, projects that up to 70 caverns, each of which could store up to 5,500 metric tonnes of hydrogen, “would be necessary to help support the arbitrage and storage that’s across all verticals, not just power,” he said. “It’s looking at heavy industries and everything else.” The site itself can support up to 100 caverns,” he noted, which could “adequately support” the entire 2050 needs for hydrogen in the West.

Millard County, a sparsely populated basin and range area within the Sevier Desert in western Utah, is notably cultivating an energy project cluster that could ultimately support the Advanced Clean Energy Storage hydrogen hub’s role in a wider scale effort to decarbonize the West, or provide crucial regional reliability. Magnum, for example, has received approval from the Federal Energy Regulatory Commission (FERC) for a gas storage project that would include the construction and operation of a natural gas storage facility, along with a 62-mile-long natural gas header pipeline. A construction schedule is as of yet undetermined, however.

FERC notably also recently prepared a final environmental impact statement for another pipeline project, the Delta Lateral Project, Kern River Gas Transportation Co.’s proposed 36-mile-long pipeline, which could deliver a firm 140,000 dekatherms of natural gas per day from Opal, Wyoming to the IPP. IPP has said it will use the new pipeline to provide the natural gas that it will initially use to generate power. Finally, Energy Capital’s 300-MW ECG Utah Solar 1 Project, is slated to be completed by 2024, potentially transmitting power to the IPP.

But according to Ducker, the ACES Delta project shines for its unique potential, which is to serve as a crucial demonstration for technology integration, with a minimal technology risk, of an end-to-end solution to produce, store, and convert renewable hydrogen for the Western U.S. The project’s regional significance has been heralded by the Western Green Hydrogen Initiative, a network of 11 western states and two Canadian provinces (along with Florida, Ohio, and Louisiana), whose mission is to scale renewable hydrogen production and use while avoiding costly transmission build-out.

The overall project, whose costs have been estimated at $1 billion, will offer a valuable service, Ducker added. “We really don’t look at this as on a dollar-per-kilogram basis because it’s just like with batteries,” he said. “When you’re looking at lithium-ion batteries, you don’t think about it as a fuel, you think about it as storage,” he noted. “So when we look at the overall project, at least as ACES has assessed it, we see the ability for the overall decarbonization goals at a 20% lower cost of electricity than if hydrogen long-duration energy storage weren’t in the mix.”

The project, Ducker predicted, will be competitive. “When we look at the production costs—if we break out just the production piece or salt cavern piece—it is competitive with today’s technologies, and what’s been put out there already,” he said.

—Sonal Patel is a POWER senior associate editor (@sonalcpatel, @POWERmagazine).

Updated (April 29): Adds details about project safety features.