New Capture Technology Holds Key to Reaching Carbon Emissions Targets

Some naysayers have argued that developing carbon capture technology for use on fossil-fueled power plants is pure folly. But research and pilot tests have continued nonetheless, and various solutions have been proven effective in capturing and utilizing carbon dioxide from flue gases. One method, examined through two UK Department of Energy & Climate Change projects, could be a game-changer.

The UK’s Climate Change Act (2008) is part of the government’s plan to reduce greenhouse gas emissions. It set out ambitious plans to reduce carbon emissions in the UK by at least 80% from 1990 levels by 2050. Five-yearly carbon budgets were put in place to support the transition, but in June 2016 the government set out impressive new targets for the fifth budget period, aiming to reduce emissions by 57% compared to 1990 levels by 2030.

Figures from the London School of Economics suggest that electricity generation currently accounts for more than 25% of the UK’s carbon emissions. It’s clear that achieving the aggressive carbon reduction targets will require a step change across the energy industry.

Most recently, the industry has looked toward renewable energy production to replace traditional electricity production, but what if the carbon produced by the existing generation processes could be captured and neutralized or, better still, turned into useful by-products that could generate new value streams or potential alternative sources of energy?

A New Carbon Capture and Exchange Technology

Several carbon capture and exchange technologies already exist, but to date, many of the processes have proven to be too expensive to develop, build, and operate to deliver a viable solution for the power industry.

Four years ago, a Bristol, England–based company looking to develop an exciting new technology to overcome these challenges approached Crown International for help. It had the technology, but needed Crown’s manufacturing expertise. A partnership was born that day. Following two successful pilot projects for the UK Department of Energy & Climate Change (DECC), the team has demonstrated not only that the technology works, but also that it delivers sufficiently in both environmental and financial terms to make it an attractive option for the industry.

The team’s new carbon capture and exchange technology uses flue gas carbon dioxide (CO2) as a feedstock for conversion into a range of valuable commodities, including formates and industrial alcohols. Data from the two DECC trials suggest that it not only captures 90% of CO2 at 99% purity, but it does so at a net present value (NPV) of just£47 per tonne of CO2 abated, compared to up to£75 per tonne for some existing technologies. (NPV is the present value of a sum of money in contrast to some future value it will have when it has been invested at compound interest.)

As you’d expect from the name, the method utilizes a two-stage carbon capture and exchange process. In stage one, the flue gas is captured from the power plant’s flue stack at temperatures up to 270C. It is then cooled via a bespoke condensing economizer, which recovers heat and water, and also acts as the input gas monitoring point. From there, the gas moves into a wash column, where a continually circulating metal-ion solution acts as the gas capture and carrying medium, removing and transforming any NOx and SOx present.

Once that process is complete, the conversion process gets underway. The remaining CO2 flows into a second-stage wash column where the gas is captured and separated. It then undergoes further processing via a patented methodology in which it is converted into high-grade hydrocarbon gas and/or by-products for on-site reuse or sale.

Opportunities exist to convert the output into harmless carbonates and bicarbonates for direct, safe deposit into the sea or into a diverse set of products, including formic acid, ethylene, methanol, syngas, and with additional feed materials, sulfuric acid. The remaining remediated cooled flue gas is then emitted from the wash column stack, which also acts as the output gas monitoring point. The process does not require elevated temperatures and pressures, nor does it produce any waste products that require disposal.

Modular Design Offers Flexibility

Where the technology really scores is that it uses a modular design (Figures 1 and 2), allowing it to be easily retrofitted onto existing power stations and scaled up or down. It was originally developed to suit industrial locations generating anywhere between 5,000 and 100,000 tonnes of CO2 per year, where other technologies aren’t economically viable.

|

| 1. Flexible deployment. The carbon capture and exchange technology is modular by design and can be scaled up or down, as needed. Courtesy: Crown International |

|

| 2. Organized layout. The carbon capture and exchange cell is shown here inside the shipping container. Courtesy: Crown International |

The fact that it takes just one to two years to install, from design to production, means operators can begin to see a return on their investment within just one year. Combine that with the fact that independent consultants have assessed the technology as offering operating cost reductions of between£840,000 (versus advanced amine processes) and£1,470,000 (versus monoethanolamine); capital expenditure savings of£855,000 NPV; and likely upward carbon levy pressures creating a pressing need for savings, and the financial incentives for adoption are clear. That’s even before a projected value stream of about£22 million per year for the carbon captured and converted, in this particular case into formic acid, is taken into account.

DECC Studies Proved the Concept

The first DECC project was a£5.2 million, three-year carbon capture project, designed to deliver a cost/tonne of CO2 abated significantly lower than current carbon remediation technologies—principally carbon capture and storage amine-based processes. The project was hosted and developed on a site in South Wales. The new technology successfully abated 95% of the CO2 captured from a natural gas boiler–generated flue gas stream, using the approximate 10,000 tonne CO2 per annum capture capacity equipment.

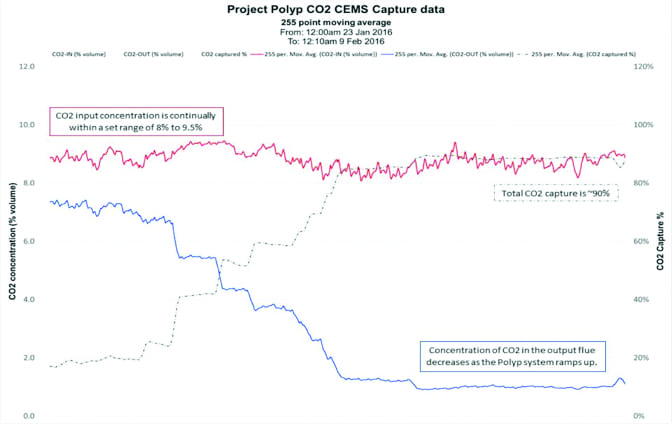

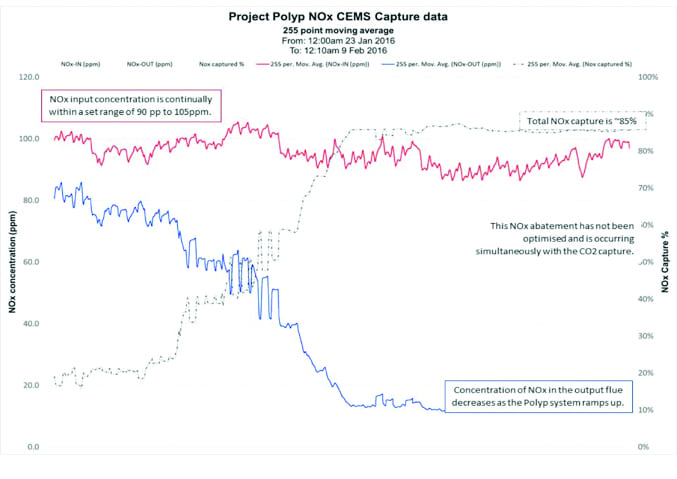

The results shown in Figures 3 and 4 are from the first two weeks of operation. The data clearly demonstrated the system’s ability to capture both CO2 and NOx flue gas emissions in ambient conditions.

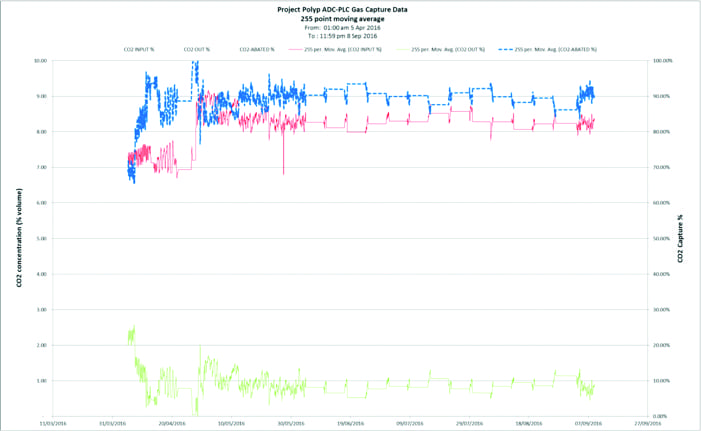

Another essential component of the South Wales project was the need to prove the long-term performance characteristics of the electrochemical cells in removing near 100% of the CO2 from fossil fuel flue gas emissions (Figure 5). This is important as fouling and mineral deposition in the electrochemical cells have traditionally been a stumbling block to developing the technology—an issue the team needed to prove could be overcome using this new proprietary technology.

Carbon Conversion

The second DECC project was a nine-month research and development project to convert CO2 into high-grade formic acid, using a process and at a cost that would make the technology commercially viable. The team’s goal was to develop, build, and demonstrate a complete system that could utilize captured CO2 and, rather than consider it a waste product, create a viable revenue stream while maintaining a low-carbon footprint for the capture and utilization of CO2.

In the DECC project, the system took a CO2 feed from pressurized cylinders, but in a deployment situation it would interface directly with the carbon capture system to utilize the captured flue gas CO2.

The pilot plant demonstrated the ability to convert 100% of CO2 into formic acid. It also demonstrated a production capacity with a product value stream of more than£8 million per annum (for this single site), at significantly lower cost than current methods of production.

By combining these two projects, the team proved the complete carbon capture and exchange technology, using flue gas CO2 as a feedstock for conversion into a range of valuable commodity products, such as formates and industrial alcohols.

Creating Value Streams

As part of the second DECC project, the team carried out a detailed review of the global formic acid market to evaluate the potential value of this by-product revenue stream, which is just one of many possible by-products. Findings from the study suggested that, while concentration within the industry is relatively high (the industry’s top 15 producers account for 88% of industry production), production is expected to increase at a compound annual growth rate of 1.34% from 2017 to 2022.

Margins in the industry, based on factory gate prices and input costs, are typically tight at about 14%, reflecting the high cost base of existing methods of production, but a significant component of this is the reliance on feedstock chemicals as part of the process. Consequently, there is a real opportunity for disruptive technologies that can deliver relatively low setup and operating costs while meeting the relevant compliance regulations, creating a valuable potential revenue stream for companies using efficient new technology.

Most importantly, the role that adopting such innovative technology could play in helping the UK and other countries reach carbon emission targets should not be underestimated. The DECC projects demonstrated that the process could simultaneously capture in excess of 95% of CO2 and 85% of NOx in the pilot sites’ flue gas emissions.

By treating carbon as a raw material feedstock for the production of valuable formates, rather than as an expensive waste material to be disposed of at high financial and environmental cost, the process creates a value stream from the by-products that makes this more environmentally-friendly approach commercially appealing.

Reusing by-products, rather than releasing them into the atmosphere, has the potential to significantly reduce CO2 emissions across the energy generation sector. It’s a promising and versatile process that produces a variety of commercial organic compounds, depending on the individual setup of the conversion cell.

If, as the London School of Economics report states, the electricity sector is responsible for 25% of current carbon emissions, then capturing 95% of CO2 emissions from fossil-fueled power plants would be a significant step forward on its own. But, with the energy generation and industrial sectors combined being responsible for 42% of UK CO2 emissions, adopting this technology across both sectors could represent the step-change the world is looking for.

The key to success of any carbon capture technology lies in making sure it is commercially attractive enough for energy companies to invest time and resources in adopting the solution. The results of the DECC trials suggest the benefits of this particular new technology warrant that investment. ■

—Mark Stacey is managing director of Crown International, a UK-based company with a background in new product design and manufacture that provides components for carbon capture projects.