3-D Laser Scanning of Nuclear Plant Piping Systems Reduces Radiation Exposure

It’s no secret that high-radiation areas are scattered throughout nuclear power plant facilities. The challenge is getting work done in those areas while keeping exposure to workers as low as possible. On one project, a novel 3-D laser scanning system was utilized to effectively map piping systems and determine where high-point vents should be installed, while reducing time in high-radiation areas and the subsequent dose to workers.

Nuclear power has long been a clean, dependable source of energy throughout the world. However, as power plants age, reliability concerns grow.

Many components make up the infrastructure of a nuclear power plant, and unsurprisingly, some of the systems are contaminated with radioactive material. Management at nuclear facilities place great importance on reducing radiation and contamination exposure to personnel, equipment, and the surrounding environment.

One of the biggest sources of this radiation and contamination comes from the vast network of pipes throughout the plant. In a pressurized water reactor (PWR), the primary coolant (water) is transported through a closed system of pipes and other components. The radioactive water is pumped under high pressure to the reactor core where it is heated by the energy released through fission of uranium atoms. The heated water then flows through the pipes to a steam generator, where thermal energy is transferred to the secondary system, generating steam that flows to turbines, spinning electric generators. If there were to be a failure anywhere in the piping system, it could force a plant offline for repairs.

Maintenance Requires an Innovative Solution

At one Midwestern PWR, there was a concern that some of these critical piping systems were experiencing wear from corrosive agents, which could result in leaks. The problem had the potential to subject personnel to dangerous and unexpected situations.

Because the corrosion in question was occurring on the inside of pipes, it was obviously an unseen problem during visual inspections. One of the potential sources of the corrosion was determined to be gases trapped in the pipes. Gases often accumulate in system high points. Inside a pipe, an unintended high point can become a resting spot for gases and a potential area of concern for catastrophic corrosive breakdown.

The concern was so significant that the plant decided to take measurements on several of its pipe runs to assess the problem. Once the high points were identified, vents would be installed to allow trapped gases to be released, when necessary.

As simple as it sounds, the effort was not without tremendous risks because many of the systems were difficult to access and had high-radiation levels. At the time, the only known way to measure these systems was with manual hand tools. The involved process would have resulted in many personnel being exposed to high levels of radiation, potential contamination, and other risks such as using ladders and scaffolding.

Hand measuring can be an effective tool for dimensional inspection, but in this case it was not sufficient. Any high point, as small as it might be, offered a place for gases to collect and cause corrosion. Typical conventional surveying with a tape measure, ladders, and scaffolding was determined to be an undesirable method for this facility. The inaccuracy and potential for human errors with hand measurements could very well result in subtle elevation changes being missed. The contractor responsible for the project immediately recognized the risk and directed its client to Exact Metrology Inc. for assistance.

After conferring with project management, reviewing the site conditions, and understanding the critical elements of the project, four metrology professionals from Exact Metrology were deployed to the facility. While donning full anti-contamination protective suits, the personnel scanned piping in more than two-dozen rooms throughout the power plant, utilizing Leica high-definition scanning (HDS) equipment (Figure 1).

3-D Laser Scanning Benefits

The Leica scanners are capable of capturing full-volume, 360-degree, 3-D point clouds (Figure 2) in about three minutes. Some rooms only required a single setup, which resulted in minimal exposure times in the potentially hazardous nuclear environment.

|

| 2. Tracing pipes. This image shows a 3-D pipe run scanned at a Midwestern nuclear power plant. Reactor containment walls were removed in the virtual environment. Courtesy: Exact Metrology Inc. |

Once a scan was initiated, the data acquisition was completely automated, allowing the metrologist to retreat to low-dose areas while critical data continued to be captured by the device. Once scanning was completed, the multiple scan setups were stitched together to form one large point cloud (Figure 3). This allowed the users to extract data from any section of the pipe run and from any perspective.

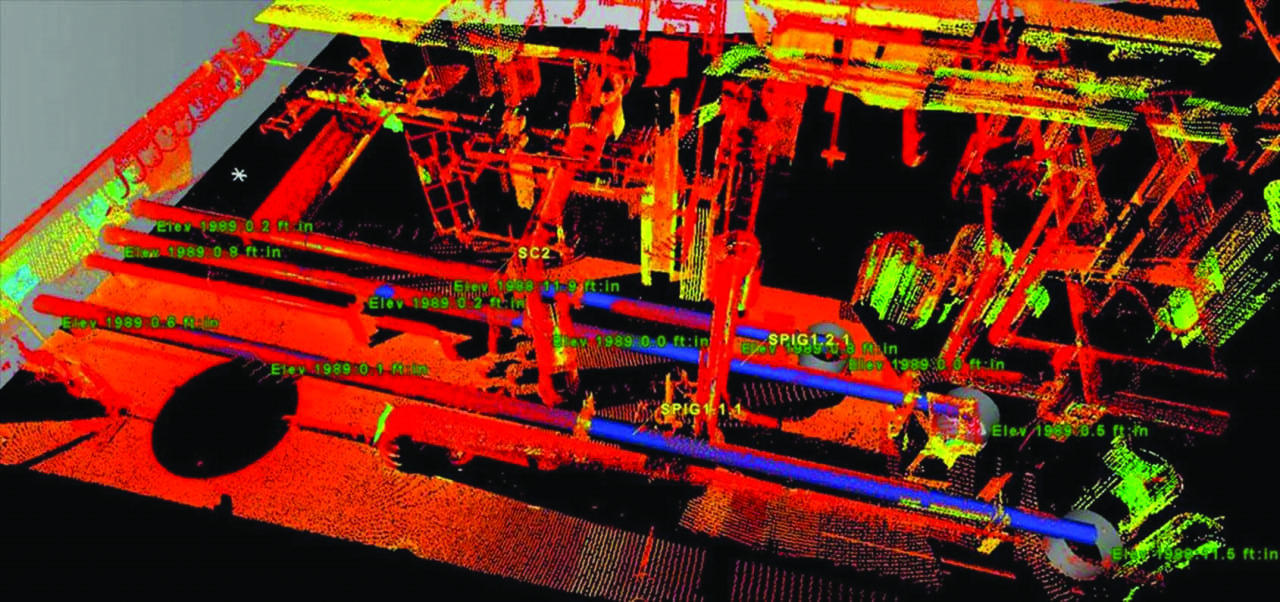

|

| 3. Getting the full picture. This image shows an isometric view of several pipe runs with high-point elevations denoted in several places. Courtesy: Exact Metrology Inc. |

Complex software algorithms then provided a function to extract all pipe sizes, centerlines, and positions, even when only parts of the pipes were scanned. As an added benefit, the dense point cloud obtained was able to reveal areas of crystallization, which indicated that leaks in the pipes had already developed.

The advantages of using 3-D scanning versus the traditional tape measure and ladder were numerous. The elimination of human error, greater accuracy, and speed were some obvious upsides. Operator safety, especially in high-radiation and high-contamination areas, was greatly increased due to the speed and operational characteristics of the scanners, which allowed operators to spend minimal time in dangerous rooms.

The scanners allowed operators to take measurements from the ground, avoiding the danger associated with ladders, scaffolding, and harnesses. Scanning from ground level also avoided the need for some work permits—which would have been required to climb ladders above a certain level—fall protection, air monitoring in higher elevations, and contact with possible contaminated surfaces above.

Another advantage of 3-D imaging over other methods is that it allows additional measurements to be taken after-the-fact. With standard measuring, once technicians have left a site, if a measurement was missed or additional measurements were determined to be necessary, they would have to return to re-measure. If the plant was back online, re-entry might not be possible.

However, with 3-D scanning the data is picture quality. By viewing the file on a computer, technicians can revisit the facility virtually, using the point cloud, and extract the required data without an additional site visit.

Once scanning was completed, 3-D computer-aided design models were generated and computer snapshots were recorded with elevation descriptors marked on each side of the pipe runs. The report showed a graphical description of the model pipes with the elevation provided in a PDF form.

The reports were sent to facility engineers to determine where to install vents on the pipe runs. The test results were found to be useful and the plant was able to take action to correct the problem. Due to the proprietary nature of the nuclear power plant facility, no further results were made available.

The folks in health physics were probably some of the happiest about the project. The dose levels that the crew received were substantially lower than ALARA (as low as reasonably achievable) goals set at the beginning of the task. ■

—Greg Hoeting is a high-definition surveying application specialist for Exact Metrology (www.exactmetrology.com).